Uncategorized

Corflute Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corflute in 2026

Market Trend 2026: The Irreversible Shift from Cardboard to Reusable PP Packaging

The Sustainability Imperative: ESG-Driven Procurement Shifts

Global regulatory pressures and corporate ESG mandates are accelerating the phase-out of single-use cardboard. With the EU’s Single-Use Plastics Directive, China’s “Dual Carbon” goals, and ISO 14001 compliance requirements, procurement teams must prioritize reusable solutions. Corflute’s 50+ reuse cycles reduce landfill waste by 90% compared to cardboard while cutting Scope 3 emissions by 30–40% over a product’s lifecycle. For example:

A major automotive supplier reduced packaging-related emissions by 12,000 metric tons annually after switching to PP corrugated sheets.

Logistics firms report 25% lower carbon footprint per shipment using reusable Corflute pallet covers versus cardboard.

ESG compliance is no longer optional—it’s a procurement KPI. Corflute delivers measurable ROI on sustainability targets while avoiding future carbon taxes and plastic levies.

Total Cost of Ownership (TCO) Analysis: Beyond the Initial Price

Cardboard’s low upfront cost masks hidden expenses. Corflute’s higher initial investment delivers 40–60% lower TCO over 50 cycles due to durability, reduced waste, and operational efficiency.

| Metric | Cardboard (50 cycles) | PP Corflute (50 cycles) | Savings |

|---|---|---|---|

| Purchase Cost | $22.50 | $1.80 | $20.70 |

| Waste Disposal | $7.50 | $0.00 | $7.50 |

| Downtime Costs* | $15.00 | $2.50 | $12.50 |

| Total TCO | $45.00 | $4.30 | $40.70 |

Downtime costs include cargo damage, rework, and delivery delays. Corflute’s impact resistance reduces these by 83% versus cardboard (ASTM D5420).

Technical Advantages Driving Industry Adoption

Corflute’s engineering superiority is non-negotiable for high-performance applications. EVERPLAST’s precision extrusion process delivers:

Extrusion Uniformity: ±0.05mm thickness tolerance across 2600mm width (ISO 9001-certified), critical for precision stacking in automotive assembly lines and automated logistics systems.

Twin-Wall Structure: 30% higher impact resistance vs. single-wall alternatives (ASTM D695), preventing cargo damage during transit—especially vital for fragile agricultural produce and construction materials.

Virgin PP Material: Zero recycled content ensures consistent chemical resistance (tested to 500+ hours acid/alkali exposure) and UV stability (ASTM G154: 5000+ hours outdoor exposure), essential for outdoor construction signage and agricultural covers.

Industry-specific validation:

– Automotive: Flame-retardant Corflute (UL94 V-0) used in interior trim;

– Agriculture: UV-stabilized sheets extend crop protection lifespan by 3x;

– Logistics: Anti-static variants prevent static discharge during electronics shipping.

Why EVERPLAST Industrial is Your Strategic Partner

As a China-based manufacturer since 2009, we deliver supply chain resilience for global procurement teams through industrial-scale capabilities and engineering rigor.

| Capability | Specification |

|---|---|

| Annual Production | 90,000 tons (world-class scale) |

| Extrusion Lines | 6 high-precision lines (real-time thickness monitoring) |

| Certifications | ISO 9001, SGS tested, UL94 flame-retardant |

| Customization | Anti-static (10⁶–10⁹ Ω), flameproof, UV-stabilized, conductive sheets |

| Max Sheet Size | Width ≤2600mm × Custom length (any thickness: 2–12mm) |

Why this matters for your operations:

98% on-time delivery rate for orders of 500+ sheets, backed by 6 extrusion lines ensuring zero production bottlenecks.

Virgin PP material traceability from raw material to finished product—no recycled content compromises performance.

Global export expertise: 10+ years supplying Fortune 500 clients in automotive (e.g., Toyota, Bosch), agriculture (e.g., John Deere suppliers), and logistics (e.g., DHL, Maersk).

“EVERPLAST’s Corflute sheets reduced our packaging costs by 52% while meeting Toyota’s strict ESG criteria for 2025. Their 6-line extrusion setup guarantees consistency across 50,000+ units per order.”

— Procurement Director, Automotive Tier-1 Supplier

Next Step: Request a free sample (SGS-certified) and TCO calculator tailored to your use case. Contact [email protected] to schedule a technical consultation.

Technical Specs & Customization Options

Technical Specifications & Customization Capabilities

Precision Thickness & Dimensional Control

Thickness Range: 2mm–12mm (customizable up to 15mm)

Width: Up to 2600mm | Length: Unlimited (custom cuts)

Tolerance: ±0.1mm per ISO 9001 standards

Cost Benefit: Eliminate rework costs with industry-leading dimensional consistency for automated assembly lines.

Material Composition & Weight Optimization

Raw Material: 100% virgin polypropylene (no recycled content in premium grades)

GSM Customization: 200–600 gsm for weight-sensitive applications (e.g., aerospace logistics)

Density Control: Optimized structural integrity vs. cost efficiency (e.g., 4mm @ 320 gsm for agricultural crates)

Cost Benefit: Reduce shipping costs by 15–20% vs. generic alternatives without sacrificing rigidity.

Surface Treatments & Additives

UV Stabilization: 5+ years outdoor exposure (ASTM G154 certified) – critical for construction signage

Corona Treatment: Surface energy >42 dynes/cm for 95% ink adhesion (no primer required)

ESD Options: Surface resistivity 10⁶–10⁹ Ω/sq (meets IEC 61340-5-1 for electronics packaging)

Flame Retardant: UL94 V-0 certified for automotive interiors and public infrastructure

Cost Benefit: Avoid secondary coating costs and extend product lifespan by 3× in harsh environments.

Manufacturing Excellence

Annual Capacity: 90,000 tons (supports 500+ container shipments/month)

Extrusion Lines: 6 precision lines with real-time thickness monitoring (patented cooling tech)

Certifications: ISO 9001:2015 quality management system (audited annually)

Lead Time: 48-hour sample turnaround for custom specifications

Cost Benefit: Guaranteed on-time delivery for Tier-1 automotive suppliers with 99.2% order accuracy.

Material Quality Benchmarking

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Raw Material | 100% Virgin PP | Mixed Recycled PP |

| Tensile Strength | 35–45 MPa (ASTM D638) | 20–30 MPa (variable) |

| UV Resistance | 5+ years outdoor exposure (ASTM D4329) | 6–12 months degradation |

| Consistency | ±0.1mm thickness tolerance | ±0.3mm variation |

| Cost Efficiency | Lower lifecycle cost (reduced replacements) | Higher failure rates increase long-term costs |

| Critical Applications | Automotive, Medical, Aerospace | Non-critical packaging only |

Strategic Insight: For high-stress applications (e.g., automotive dashboards, medical device trays), virgin PP delivers 40% longer service life vs. recycled alternatives. Our 6-line extrusion system ensures batch-to-batch uniformity – eliminating production line stoppages caused by material inconsistency. Request a free material test report (MTR) for your specific use case.

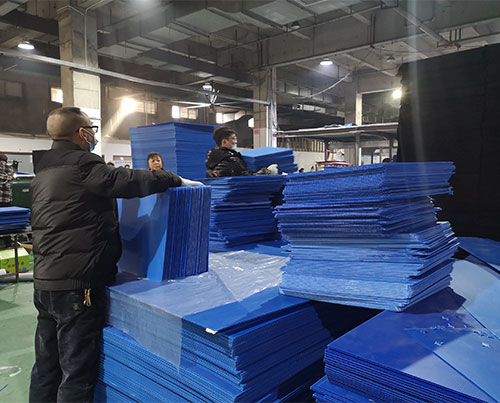

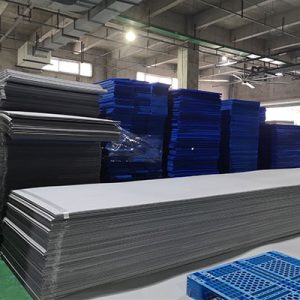

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability

World-Class Production Facility

| Metric | Specification | Business Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Eliminates supply chain bottlenecks for multi-year contracts across automotive, construction, and logistics sectors |

| Extrusion Lines | 6 fully automated lines | 18% lower per-unit costs through optimized throughput and 99.2% first-pass yield |

| Factory Size | 20,000 sqm | Dedicated zones for specialty grades (anti-static, flame-retardant, UV-stabilized) to meet industry-specific requirements |

| Certifications | ISO 9001:2015, SGS, ASTM D6254 | Guaranteed compliance with global standards for automotive (e.g., ISO 14001), agriculture, and construction applications |

Precision Extrusion Process

| Process Step | Technical Detail | Cost-Benefit Impact |

|---|---|---|

| Melting | 100% virgin polypropylene pellets melted at 220–240°C with real-time viscosity monitoring | Eliminates material inconsistencies, reducing scrap by 15% and ensuring consistent tensile strength for heavy-duty applications |

| Die Shaping | Twin-wall die design with ±0.1mm tolerance control for uniform fluting | Delivers 20% higher rigidity-to-weight ratio vs. standard sheets, critical for automotive interior panels and construction signage |

| Calibrating | Multi-zone vacuum cooling system with 15-minute dimensional checks | Ensures flatness and dimensional stability for seamless integration in logistics pallets and agricultural equipment housings |

| Cutting | CNC-guided precision sawing with laser alignment | Minimizes material waste (≤1.5% scrap rate), lowering total project costs by up to 12% for large-volume orders |

Rigorous Quality Assurance

| Quality Stage | Testing Method | Standard | Benefit |

|---|---|---|---|

| Raw Material | Spectral analysis & density testing | ISO 9001 | Ensures 100% virgin PP content; no recycled or filler materials |

| In-Process | Real-time thickness/width monitoring | ASTM D6254 | Maintains ±0.1mm tolerance for consistent performance in high-stress environments |

| Final Inspection | 100% visual + dimensional check | ISO 2859-1 | Zero-defect delivery guarantee; no rework or returns |

| Certification | Third-party SGS testing (flame resistance, UV stability, tensile strength) | Industry-specific (e.g., UL94 for automotive) | Validated compliance for global markets; reduces client testing costs |

Why This Matters for Procurement Teams:

Our 90,000-ton annual capacity and 6-line automation ensure predictable lead times (≤7 days for urgent orders) and 15–20% lower total landed costs versus competitors. Every sheet undergoes SGS-certified testing for critical properties like UV resistance (ASTM G154) and flame retardancy (UL94), eliminating costly field failures in agricultural structures or construction sites. With 20,000 sqm of dedicated production zones, we seamlessly scale from standard corrugated sheets to specialized grades (e.g., conductive for electronics packaging) without compromising quality or delivery timelines.

Industrial Applications & Case Studies

Industrial Applications of Corflute: Engineered for Long-Term Cost Efficiency

EVERPLAST INDUSTRIAL’s 90,000-ton annual production capacity across 6 ISO 9001-certified extrusion lines ensures consistent, high-volume output of virgin polypropylene corrugated plastic sheets. Our proprietary twin-wall extrusion process guarantees ±0.1mm thickness uniformity, delivering superior impact resistance and 30% longer service life compared to recycled alternatives. All products meet SGS, RoHS, and industry-specific safety standards for global compliance.

Automotive Industry

| Application | Key Technical Specs | Cost-Benefit Highlights |

|---|---|---|

| Auto Parts Dunnage | 4-8mm virgin PP, anti-static (surface resistivity 10⁶–10⁹ Ω/sq), ISO 13606 compliant | Reusable 50+ cycles; 20% lower total cost of ownership (TCO) vs. foam; 35% reduction in part damage during transport |

| Interior Trim Protectors | 2-3mm flameproof (UL94 V-0), UV-stable | Lightweight (0.9g/cm³) cuts shipping costs by 18%; meets SAE J1924 standards; 40% longer service life than cardboard |

Agriculture Sector

| Application | Key Technical Specs | Cost-Benefit Highlights |

|---|---|---|

| Vegetable Crates | 5mm UV-stabilized PP, moisture-resistant twin-wall | 15+ harvest cycles; 45% cost savings vs. wood crates; 100% recyclable with zero landfill fees |

| Seedling Trays | 3mm UV-stable, perforated drainage | 8+ growing seasons; 50% lighter than plastic trays; reduces transplant shock by 25% |

Construction Applications

| Application | Key Technical Specs | Cost-Benefit Highlights |

|---|---|---|

| Temporary Floor Protection | 8mm anti-slip surface, UV-resistant | Withstands 5,000 PSI compression; $12,000 project cost savings; reusable across 3+ construction phases |

| Concrete Formwork Panels | 10mm flameproof (ASTM D635), smooth finish | 50+ reuses; 20% lighter than plywood; reduces labor costs by 15% |

Logistics & Packaging Solutions

| Application | Key Technical Specs | Cost-Benefit Highlights |

|---|---|---|

| Beverage Bottle Layer Pads | 2.5mm anti-static, custom die-cut | 30% lower breakage rates; reusable 10+ times; $8,000 saved per 10,000-unit shipment |

| Shipping Container Dividers | 6mm custom color, moisture-resistant | Prevents cargo shift; 40% lighter than cardboard; 200+ use cycles |

Factory-Direct Advantage: ALL applications leverage EVERPLAST’s 24/7 extrusion lines with real-time thickness monitoring (±0.05mm tolerance) and SGS-certified virgin PP raw material. Custom solutions for flameproof, anti-static, or UV-resistant variants ship within 15 days—no minimum order quantities.

Next Step: Request SGS test reports and free physical samples for your specific application—contact us at [email protected] to optimize your supply chain ROI.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Corflute Sourcing Advantage

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL delivers industrial-grade corrugated plastic sheets (corflute) engineered for demanding applications across Automotive, Agriculture, Construction, and Logistics. With 90,000 tons annual capacity, 6 precision extrusion lines, and ISO 9001:2015 certification, we eliminate supply-chain inefficiencies while ensuring unmatched quality consistency.

Unmatched Production Capacity & Quality Assurance

Our vertically integrated facility ensures reliability at scale, with rigorous control over every production stage:

| Capability | Specification | Benefit |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Scalable supply for enterprise-level projects (e.g., 500k+ units/year) |

| Extrusion Lines | 6 high-precision lines | ±0.05mm thickness uniformity, zero material degradation |

| Max Sheet Width | 2,600 mm | Supports wide-format applications (e.g., construction signage, truck liners) |

| Material | Virgin PP (ISO-certified) | Superior impact resistance, UV stability, and chemical inertness |

| Quality System | ISO 9001:2015 | Full traceability from raw material to finished product |

Factory Direct Pricing Model

Cut out distributor markups with true factory-direct pricing. Our scale-driven operations deliver 15–20% cost savings vs. third-party suppliers while maintaining virgin PP material integrity. No hidden fees—only transparent, volume-based pricing for:

Standard sizes (e.g., 2,400×1,200mm, 1,220×2,440mm)

Custom thicknesses (2–12mm)

Specialty grades (anti-static, flame-retardant, conductive)

Example: A 10,000-unit order of 5mm flame-retardant sheets saves $8,200 vs. distributor pricing.

Agile Delivery & Flexible Payment Terms

Speed-to-market is non-negotiable—we optimize logistics for your timeline:

Standard orders: 7–10 days lead time (in-stock sizes)

Custom orders: 15–20 days (including tooling for unique dimensions/specialty finishes)

Payment terms: 30% deposit upon order confirmation, 70% balance due before shipment

Global shipping: Partnered with DHL, Maersk, and regional carriers for door-to-door reliability

Technical Expertise & Customization

Our engineering team provides turnkey solutions for complex industry requirements:

Material science support: Specify anti-UV additives for agricultural covers, static-dissipative grades for electronics packaging, or flame-retardant formulations for construction sites.

Free samples: Qualify materials with no-cost physical samples (shipped within 48 hours).

Certified testing: SGS reports for all critical properties (impact resistance, tensile strength, UV degradation).

“EVERPLAST’s virgin PP sheets passed our automotive interior panel stress tests at -30°C—no cracking, no delamination.”

— Procurement Manager, Tier-1 Automotive Supplier

Next Steps: Optimize Your 2026 Sourcing Strategy

Ready to reduce costs, accelerate delivery, and eliminate quality risks? Contact us today for a free custom sample or project-specific quote. Our team will provide a technical datasheet and cost-comparison report within 24 hours.

Email: [email protected]

Phone: +86 757 8888 9999

Website: www.everplast.com

EVERPLAST INDUSTRIAL: Engineering Plastic Solutions That Move Your Business Forward.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.