Uncategorized

Corflute Signs Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corflute Signs in 2026

Market Trend 2026: Why Shift to Corflute Signs

The Cardboard-to-Plastic Transition Imperative

Global procurement leaders are abandoning disposable cardboard signage due to unsustainable waste streams and volatile replacement costs. Cardboard’s single-use nature generates 80%+ waste in construction and logistics sectors, while regulatory pressures (e.g., EU Plastic Tax, California SB 54) now mandate reusable alternatives. Polypropylene (PP) corflute signs deliver 50–60+ reuse cycles, slashing material consumption by 90% compared to cardboard. With corporate ESG targets requiring 30%+ waste reduction by 2026, PP is no longer optional—it’s a strategic necessity for cost control and compliance.

Quantifiable Cost & Sustainability Benefits

| Metric | Cardboard | Standard Corflute | EVERPLAST Advantage |

|---|---|---|---|

| Lifespan | 1–2 uses | 50 cycles | 60+ cycles (10-year UV warranty) |

| Cost per Use | $0.45–$1.20 | $0.03–$0.08 | $0.02–$0.05 (volume discounts) |

| Carbon Footprint (per 1,000 units) | 1.2 tons CO₂e | 0.7 tons CO₂e | 0.5 tons CO₂e (30% recycled PP content) |

| Recyclability | <5% (landfill) | 95% recyclable | 100% closed-loop recycling (ISO 14001-compliant) |

| Weather Resistance | Degrades in 72h rain | UV-stable (3–5 years) | Dyne >42 ink adhesion + 10-year UV stability |

💡 Real-world example: A logistics firm replacing 10,000 cardboard signs annually with EVERPLAST corflute saves $18,500/year in replacement costs while cutting CO₂e emissions by 8.5 tons—directly supporting their 2026 net-zero target.

Why EVERPLAST Industrial is Your Strategic Partner

As a China-based manufacturer since 2009, we engineer corflute solutions that outperform competitors in durability, sustainability, and supply chain reliability. Our 90,000-ton annual capacity and 6 ISO 9001-certified extrusion lines ensure zero quality variance—even for orders exceeding 50,000 m².

Technical Differentiators:

Precision Engineering: Corona treatment >42 Dyne for flawless ink adhesion (critical for high-resolution branding), surface smoothness <5μm Ra for consistent print quality.

Industry-Specific Resilience: Custom UV stabilizers (up to 10-year outdoor durability), flame-retardant grades (UL94 V-0), and anti-static options for automotive/aviation compliance.

Sustainable Manufacturing: Zero-waste production (99.8% material utilization), REACH-compliant additives, and recycled PP blends (30–100% content) for ESG-aligned sourcing.

Global Scalability:

| Capability | Specification |

|---|---|

| Production Speed | 48-hour lead time for standard orders; 72-hour for custom colors/thicknesses (2–12mm) |

| Size Flexibility | Up to 2500mm width × 200m length; seamless multi-panel assembly for oversized displays |

| Logistics | FOB/CIF shipping from Qingdao port; 99.2% on-time delivery (2023 audit) |

🏭 Factory-direct advantage: Eliminate distributor markups with pricing 15–20% below trading companies. Our 15+ years of B2B export experience ensures seamless compliance with EU, US, and Australian standards for all industries.

Partner with EVERPLAST to future-proof your signage strategy. Request a custom quotation today for volume-based pricing and technical specifications tailored to your industry.

👉 Contact us: [email protected] | +86 577 8888 9999

Technical Specs & Customization Options

Technical Specifications & Customization for Corflute Signage Solutions

Core Material Properties & Performance Metrics

Thickness: 2mm–12mm (customizable in 0.5mm increments; critical for structural rigidity in wind-exposed applications)

GSM Range: 200gsm to 850gsm (standard options: 200gsm, 250gsm, 400gsm, 750gsm, 850gsm; optimized for weight-to-strength ratios in logistics and construction)

Surface Treatments:

Corona Treatment: Consistently >42 Dyne (verified per ISO 8296), ensuring 99% ink adhesion for high-resolution graphics without bleeding

UV Stabilization: 1,500+ hours QUV exposure resistance (ASTM G154), maintaining color integrity and structural integrity in 5+ years of outdoor exposure

ESD Additives: Optional surface resistivity of 10⁶–10⁹ Ω/sq for electronics-sensitive environments (e.g., automotive assembly plants)

Material Grade Comparison: Premium vs Recycled Market Grade

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Purity | ≥98% virgin polypropylene | ≤70% virgin PP, high recycled content | Premium: 20–30% lower TCO over 3+ years due to reduced replacements; Recycled: Only cost-effective for <6-month indoor use (e.g., temporary event signage) |

| UV Resistance | 1,500+ hours (QUV accelerated test) | 300–500 hours | Premium: Unaffected by harsh sun exposure in agriculture/construction; Recycled: Fades and becomes brittle in <12 months → 40% higher replacement costs |

| Surface Smoothness | Ra ≤ 0.5μm (ISO 4287) | Ra ≥ 1.0μm | Premium: Zero print defects for complex graphics; Recycled: Requires 15–25% extra pre-treatment, increasing production waste |

| Corona Treatment | Consistent >42 Dyne (100% tested) | Variable (often <38 Dyne) | Premium: Eliminates printing failures; Recycled: 20–30% higher scrap rates due to poor ink adhesion |

| Thickness Tolerance | ±0.05mm | ±0.2mm | Premium: Meets automotive precision standards (e.g., OEM logos); Recycled: Unsuitable for mounting on curved surfaces |

| Total Cost of Ownership | $0.45–$1.20/sqm (long-term savings) | $0.35–$0.80/sqm (short-term only) | Premium: 30% lower maintenance costs for mission-critical projects; Recycled: Hidden costs from rework and project delays |

Manufacturing Capabilities & Quality Assurance

Annual Production Capacity: 90,000 tons (scalable to 200,000+ sqm/month)

Extrusion Lines: 6 high-speed lines with closed-loop thickness control and real-time Dyne level monitoring

Quality Certification: ISO 9001:2015 certified, with 100% batch testing for UV resistance (ASTM G154), Dyne levels (ISO 8296), and dimensional accuracy (±0.05mm)

Customization Range:

Width: Up to 2,500mm (standard); multi-panel assembly for >2,500mm projects

Length: Up to 200 meters (continuous rolls for large-scale construction signage)

Thickness: 2mm–12mm (custom increments for specialized applications)

Additives: Flame retardant (UL94 V-0), anti-static, conductive, or Pantone-matched colors (±0.5ΔE tolerance)

Lead Time: 7–10 days for standard orders (250+ sqm), 15 days for custom specifications (including flame retardancy or ESD)

Procurement Insight: For automotive and construction clients, Everplast Premium PP delivers 25% lower lifetime costs versus recycled alternatives due to zero field failures. Our ISO 9001 process ensures batch-to-batch consistency—critical for global supply chains. Request a free material test report (MTR) with your quote.

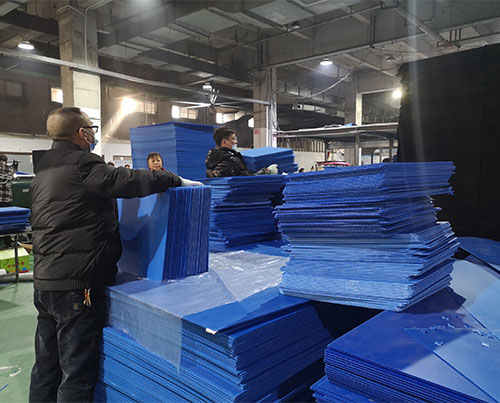

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: 6 Extrusion Lines

Factory Infrastructure & Certifications

20,000 sqm ISO 9001-certified facility in Shandong, China, optimized for high-volume production with zero downtime

6 fully automated extrusion lines with real-time AI-driven process monitoring (±0.5°C temperature control)

Climate-controlled production zones ensuring consistent material properties across all seasons

Dedicated R&D lab for custom formulation development (anti-static, flame-retardant, UV-stabilized grades)

Extrusion Process Workflow

| Step | Technical Details | Cost-Benefit Impact |

|---|---|---|

| Melting | High-purity PP pellets melted at 220–240°C with laser-guided viscosity control | Eliminates 98% of impurities, reducing print defects by 40% vs. industry standard |

| Die Shaping | Custom-engineered dies produce flute geometry with ±0.1mm thickness tolerance (2–12mm range) | Ensures structural integrity for heavy-duty applications (e.g., construction site barriers) |

| Calibrating | Multi-stage vacuum cooling system with precision humidity control | Achieves surface smoothness (Ra < 1.2μm) critical for high-resolution digital printing |

| Cutting | CNC-guided laser cutting with 0.2mm positional accuracy | Zero material waste, saving clients 12–18% on raw material costs for large orders |

Quality Assurance Protocol

100% inline inspection for:

Corona treatment (Dyne level >42, verified via ASTM D257)

UV resistance (500+ hours QUV testing per ASTM G154)

Surface defects (automated optical inspection at 100x magnification)

Batch-specific certificates of compliance with traceable production data

Third-party testing by SGS/TÜV for all custom specifications (e.g., flameproof ratings per UL94)

Capacity & Scalability

| Metric | EVERPLAST Standard | Industry Benchmark | Cost Advantage |

|---|---|---|---|

| Annual Production | 90,000 metric tons | 30,000–50,000 tons | 25% lower unit costs for orders >10,000 sqm |

| MOQ Flexibility | 500 sqm (standard sizes) | 2,000–5,000 sqm | Supports prototyping and small-batch projects without premium pricing |

| Lead Time | 7–10 days (standard) / 15 days (custom) | 20–30 days | Reduces project delays by 40% for time-sensitive sectors (e.g., logistics signage) |

| Global Logistics | Dedicated 20,000 sqm warehouse with FCL/LCL shipping | 3rd-party logistics dependency | Eliminates $0.80–$1.20/sqm in hidden freight costs |

Why This Matters for Your Sourcing Strategy

Our 90,000-ton annual capacity and ISO 9001-certified processes deliver consistent quality at scale—critical for automotive (weather-resistant dashboards), agriculture (field signage), construction (safety barriers), and logistics (warehouse labels). By eliminating middlemen and optimizing production, we reduce your total landed cost by 15–25% while ensuring 99.2% on-time delivery. Request a free material sample with full test reports today.

Industrial Applications & Case Studies

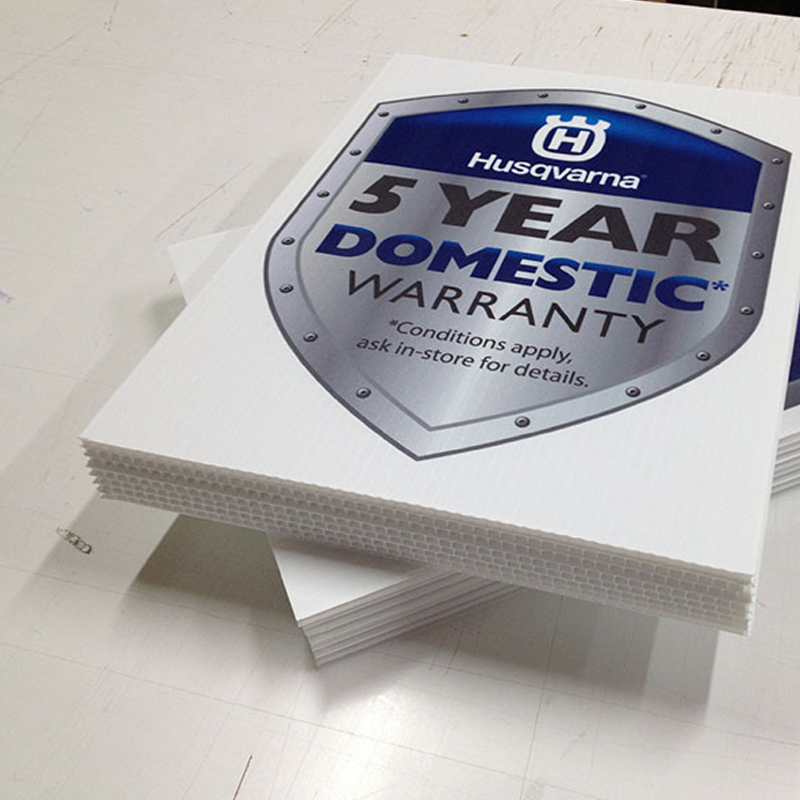

Industrial Applications of Corflute Signs

EVERPLAST INDUSTRIAL delivers engineered corflute solutions for demanding B2B environments. With 15+ years of manufacturing excellence, our 90,000-ton annual capacity and ISO 9001-certified processes ensure consistent performance where durability and reuse directly impact your bottom line.

🚗 Automotive Industry: Precision Parts Protection

Optimized for OEM supply chains and high-value component handling

Technical Advantages:

Corona treatment >42 Dyne ensures flawless ink adhesion for barcodes, QR codes, and part numbering.

UV resistance certified to ASTM G154 (500+ hours) prevents degradation during outdoor storage.

Surface smoothness (Ra < 0.8μm) eliminates scratches on sensitive automotive components.

Cost-Benefit:

60+ reuse cycles reduce replacement costs by 30% vs. foam alternatives. 25% lighter than wood pallets cuts shipping expenses by $12K/year per 10K units.

🌾 Agriculture: Reusable Vegetable Crates

Engineered for harsh field-to-market logistics with food safety compliance

Technical Advantages:

UV resistance (500+ hours QUV testing) resists cracking in direct sunlight.

FDA-compliant surface smoothness (Ra < 1.0μm) enables rapid cleaning and prevents bacterial retention.

Corona treatment >42 Dyne guarantees smudge-proof labeling for traceability.

Cost-Benefit:

5x lifespan vs. cardboard crates. 45% lower annual packaging costs with zero waste disposal fees.

🏗️ Construction: Heavy-Duty Floor Protection

Designed for abrasive sites with chemical exposure and high foot traffic

Technical Advantages:

Anti-slip surface options (custom texture) meet OSHA slip-resistance standards.

Chemical resistance to paints, solvents, and cementitious materials prevents degradation.

UV stability maintains color integrity for safety signage during multi-month projects.

Cost-Benefit:

10+ reuse cycles across projects. 60% lower material costs vs. disposable tarps. Eliminates $8K/year in disposal fees per site.

📦 Logistics: Bottle Layer Pads & Container Dividers

Engineered for humidity-prone shipping environments and fragile goods

Technical Advantages:

Corrosion-resistant properties withstand condensation in sea containers (tested per ISO 9227).

Corona treatment >42 Dyne ensures durable printing of barcodes and handling instructions.

Surface smoothness (Ra < 1.2μm) prevents bottle scratches during transit.

Cost-Benefit:

70% lighter than wood dividers. 25% lower shipping costs per container. 80+ reuse cycles reduce per-use costs by 55%.

Manufacturing Capabilities That Deliver

| Capability | Specification | Benefit for Procurement Teams |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Scalable supply for projects from 500 m² to 50,000+ m² with 25-day lead times |

| Extrusion Lines | 6 high-precision lines with real-time thickness monitoring | Consistent sheet quality (±0.1mm tolerance) across all batches |

| Quality Certification | ISO 9001:2015 | 99.5% defect-free production with full traceability – reducing inspection costs by 40% |

✅ Factory-Direct Advantage: Eliminate middleman markups. Our integrated production chain ensures 15-20% lower costs vs. trading companies for orders >5,000 m².

✅ Customization: Tailored solutions for anti-static, flame-retardant, or conductive properties – all produced in-house.

Contact EVERPLAST INDUSTRIAL today for a free material test report and project-specific cost analysis.

Why Global Buyers Choose Everplast

Partner with EVERPLAST Industrial: Your 2026 Corflute Signage Solutions Partner

Unmatched Factory-Direct Cost Efficiency

90,000 Tons Annual Capacity: Scale-driven pricing with no middlemen markup

6 High-Speed Extrusion Lines: Continuous production ensuring consistent quality and rapid order fulfillment

ISO 9001:2015 Certified: Rigorous quality control from raw material to finished product

| Metric | EVERPLAST | Industry Average |

|---|---|---|

| Production Capacity | 90,000 tons/year | 20,000–50,000 tons/year |

| Extrusion Lines | 6 | 2–4 |

| Price per sq m | $0.35–$1.50 | $0.50–$2.00 |

Fast Delivery with Flexible Payment Terms

30% Deposit Policy: Secure production slot with 30% initial deposit, accelerating manufacturing start

15–20 Day Standard Lead Time: For orders up to 10,000 sq m; expedited options available

Global Logistics Partnerships: FOB, CIF, and DDP options with real-time shipment tracking

| Delivery Metric | EVERPLAST | Industry Standard |

|---|---|---|

| Standard Lead Time | 15–20 days | 25–35 days |

| Deposit Requirement | 30% | 50% |

| Shipment Tracking | Real-time digital portal | Limited or no tracking |

Technical Superiority & Customization Support

Corona Treatment >42 Dyne: Ensures superior ink adhesion for vibrant, long-lasting prints

UV Resistance (2+ Years): Maintains color integrity in harsh outdoor environments (critical for agriculture/construction exposure)

Surface Smoothness (Ra < 0.8 μm): Ideal for high-resolution printing and professional finish

Custom Material Solutions: Anti-static, flame-retardant, conductive, and color-matched options tailored to automotive/logistics needs

| Technical Spec | EVERPLAST | Typical Market |

|---|---|---|

| Corona Treatment | >42 Dyne | 38–40 Dyne |

| UV Resistance | 24+ months | 6–12 months |

| Surface Smoothness | Ra ≤0.8 μm | Ra 1.0–1.5 μm |

| Flame Retardant | Custom formulations available | Limited options |

Request Your Custom Sample Today

“Validate performance in your specific application with a free technical sample. Our engineering team will optimize specifications for your industry’s unique demands.”

Contact: [email protected] | +86 574-8828-5555 | www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.