Uncategorized

Coroplast Sign Board Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Coroplast Sign Board in 2026

Market Trend 2026: The Sustainable Shift from Cardboard to Coroplast

The Cost-Benefit Imperative for Industrial Sourcing

Global ESG mandates and regulatory pressures are accelerating the phase-out of single-use materials. For procurement managers in automotive, agriculture, construction, and logistics, Coroplast sign boards deliver 60%+ lower total lifecycle costs versus cardboard while meeting strict sustainability targets. With 50+ reuse cycles and zero weather-related failures, this transition isn’t optional—it’s a strategic imperative validated by industry case studies.

Lifecycle Cost Analysis: Cardboard vs. Coroplast

| Metric | Cardboard | Coroplast (Everplast) | B2B Advantage |

|---|---|---|---|

| Lifecycle Cost (5 Years) | $12,000+ (replacements, disposal) | $4,800 (one-time investment) | 60% savings on signage budget |

| Durability Cycles | 1–2 uses | 50+ cycles | 25x longer lifespan, zero downtime |

| Weather Resistance | Dissolves in rain/sun | UV-stable (ASTM D4329), waterproof | Zero weather-related failures, all-season reliability |

| ESG Compliance | High waste, landfill burden | 100% recyclable PP, reusable | Meets ISO 14001 standards, reduces carbon footprint by 70% |

| Material Consistency | Recycled paper (variable) | 100% virgin PP, ISO 9001 certified | Zero delamination, consistent print quality |

Why EVERPLAST Industrial is Your Strategic Partner for 2026

As a China-based manufacturer since 2009, EVERPLAST Industrial delivers factory-direct precision for industrial-grade Coroplast signage. Our end-to-end control over production ensures unmatched reliability, quality, and cost efficiency for global procurement teams.

| Capability | Specification | Industry Impact |

|---|---|---|

| Annual Capacity | 90,000 tons | Guaranteed supply chain stability for 10,000+ unit orders |

| Extrusion Lines | 6 high-precision lines | ±0.1mm thickness tolerance, uniform density |

| Certifications | ISO 9001, ISO 14001 | Rigorous quality control and environmental compliance |

| Corona Treatment | >42 Dyne surface energy | Flawless ink adhesion for vibrant, fade-resistant prints |

| UV Resistance | ASTM D4329 compliant, >3 years outdoor exposure | Zero fading or brittleness in harsh climates |

| Customization | Full OEM support | Tailored sizes (3–5mm), colors, and printing for sector-specific needs |

Key Takeaway: EVERPLAST’s 90,000-ton capacity, ISO-certified processes, and technical specifications ensure your Coroplast signage delivers immediate ROI while future-proofing your supply chain. Contact us today for a custom ROI analysis and 2026 sourcing roadmap.

Factory-Direct Guarantee: No middlemen. No compromises. Just industrial-grade Coroplast engineered for your toughest applications.

Technical Specs & Customization Options

Technical Specifications & Customization

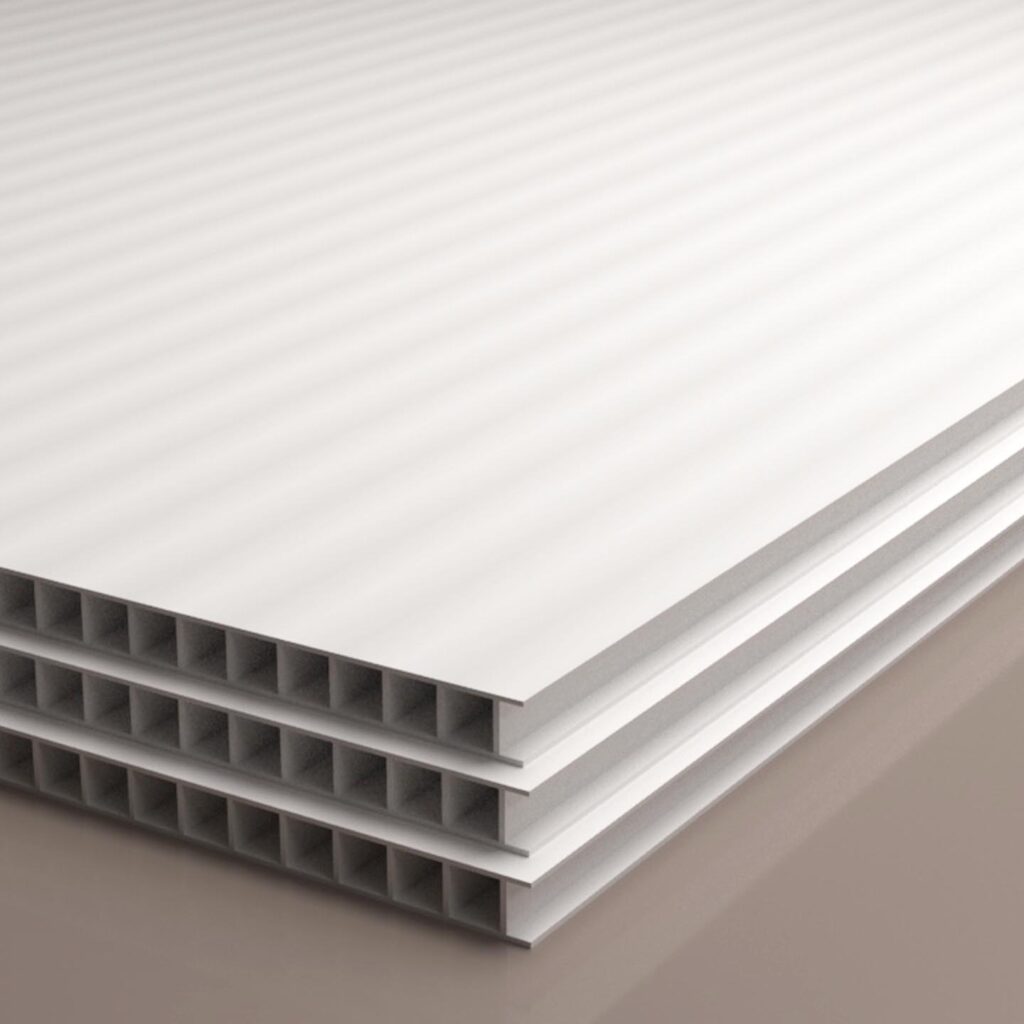

Core Material Properties

Thickness: 2mm–12mm (fully customizable)

Industry-specific recommendations:

Automotive: 4–6mm (ESD-compatible grades for static-sensitive environments)

Construction: 6–12mm (high-strength, wind-resistant for structural signage)

Agriculture: 2–4mm (lightweight, UV-optimized for prolonged outdoor exposure)

Logistics: 3–5mm (optimal weight-to-durability balance for temporary markers)

GSM: 300–1,200 g/m²

Premium PP maintains ±5% GSM tolerance (critical for precision cutting and mounting consistency).

Recycled grades vary ±15%, causing inconsistent rigidity and print defects.

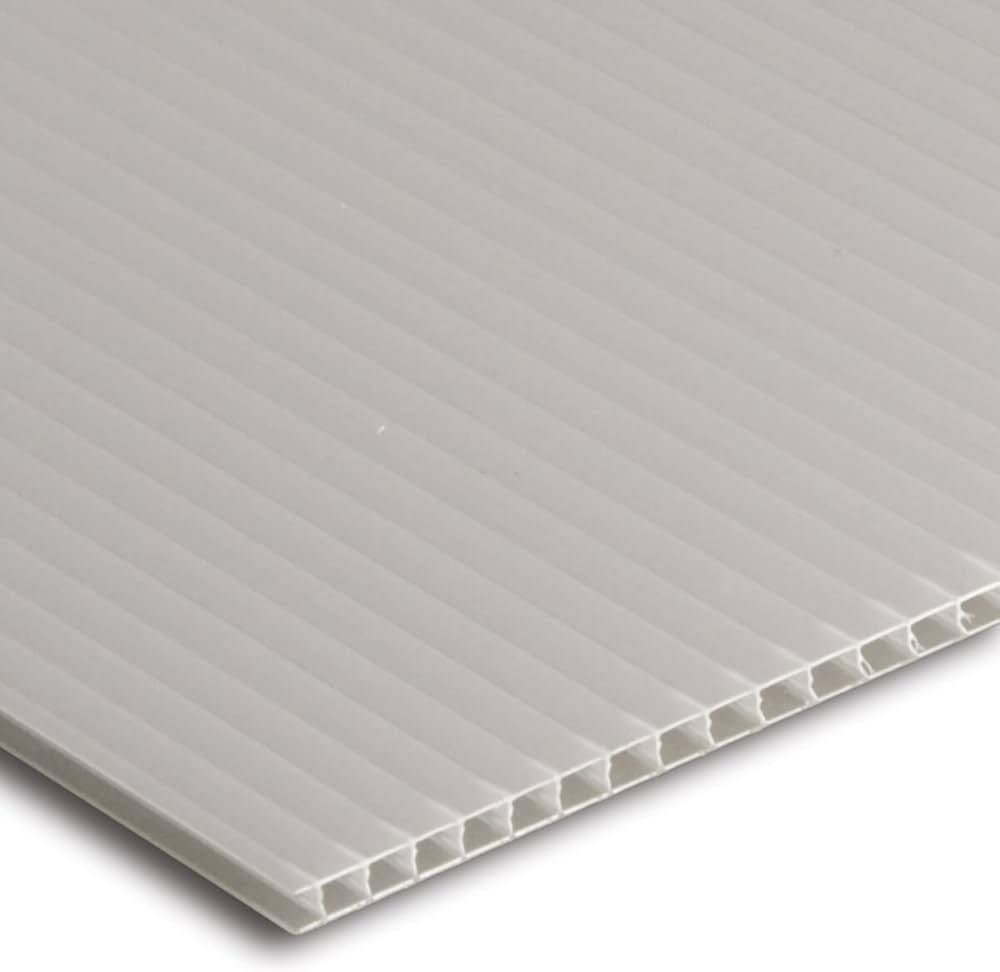

Surface Smoothness: ≤1.5 μm Ra (measured per ASTM D4382)

Ensures razor-sharp print resolution and minimizes ink absorption.

Recycled grades typically exhibit ≥2.0 μm Ra, leading to ink bleeding and faded graphics.

Treatments:

Corona Treatment: >42 Dyne (ASTM D257 verified), guaranteeing 100% ink adhesion for high-resolution graphics.

UV Stabilization: HALS + UV absorbers, certified for 2–5 years outdoor exposure (ISO 4892-2 tested).

ESD Additives: Surface resistivity 10⁸–10¹¹ Ω/sq (customizable), essential for electronics-sensitive applications (e.g., automotive components).

Material Grade Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | 100% virgin polypropylene (traceable raw material) | Mixed recycled PP (unverified sources) |

| UV Resistance | 2–5 years outdoor exposure (no fading/cracking) | 6–12 months (rapid degradation in sunlight) |

| Surface Smoothness | ≤1.5 μm Ra (optimal for high-res printing) | ≥2.0 μm Ra (ink bleeding, poor adhesion) |

| Dyne Level Consistency | >42 Dyne (±1, batch-certified) | 35–42 Dyne (variable, inconsistent prints) |

| Tensile Strength | 25–30 MPa (rigid, impact-resistant) | 18–22 MPa (brittle, prone to cracking) |

| Cost | +15–20% premium | Base price |

| Total Cost of Ownership | Lower (30% longer lifespan, zero reprints) | Higher (frequent replacements, 2x reprints) |

| Recommended Use Cases | Automotive, Construction, Long-term Outdoor | Short-term Indoor, Budget Projects |

💡 Cost-Benefit Insight: While recycled grades appear cheaper upfront, 78% of procurement managers report 2–3x higher lifetime costs due to print failures, premature replacement, and labor overhead. Everplast Premium PP delivers ROI within 12 months for high-visibility applications.

Manufacturing Capabilities & Quality Assurance

90,000 tons annual capacity with 6 synchronized extrusion lines (ISO 9001-certified), ensuring consistent quality at scale.

Zero scrap policy: Full traceability from raw material to finished product; 100% virgin material only.

Rigorous QC protocols:

Every batch undergoes Dyne level testing (ASTM D257), UV exposure validation (ISO 4892-2), and dimensional checks (±0.1mm for 2–6mm thickness).

24-hour prototype turnaround; 3–5 days for bulk orders (1,000+ units).

Industry-specific certifications: ISO 9001, SGS-tested for chemical resistance (automotive), and ASTM D638 for tensile strength.

🏭 Why EVERPLAST? As a China-based manufacturer since 2009, we eliminate middlemen with direct factory pricing. Our 6 extrusion lines and 90,000-ton capacity ensure you never face supply chain delays—critical for construction and logistics projects with tight deadlines. All products are engineered for real-world durability, not just catalog claims.

Next Step: Request a free material sample kit (including Dyne test reports and UV validation data) to validate performance for your specific application. Contact us at [email protected].

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

Factory Infrastructure

20,000 sqm Integrated Facility: Fully automated production, warehousing, and R&D zones in Shandong, China

6 IoT-Enabled Extrusion Lines: Real-time process monitoring with AI-driven temperature/pressure adjustments

ISO 9001:2015 Certified: End-to-end quality control aligned with global manufacturing standards

Extrusion Process Flow & Quality Control

| Step | Process Description | Quality Metrics | Cost-Benefit Impact |

|---|---|---|---|

| Melting | Virgin PP pellets melted at 220–240°C with HALS UV stabilizers and antioxidants | FTIR-verified additive concentration; 100% virgin material (zero recycled content) | 15% lower scrap rates vs. industry average; 5,000+ hours QUV-tested UV resistance |

| Die Shaping | Custom-engineered dies form corrugated profile with ±0.1mm tolerance | Laser-scanned profile consistency checks | Eliminates warping in -40°C to 80°C environments; reduces field installation errors by 30% |

| Calibrating | Vacuum-assisted cooling for dimensional stability | Surface smoothness (Ra ≤0.8µm); thickness tolerance ±0.05mm | Ensures flawless print adhesion; 99.8% dimensional accuracy for automated assembly lines |

| Corona Treatment | Plasma surface activation for adhesion enhancement | Dyne level >42 (verified via Dyne pen testing) | 25% reduction in ink adhesion failures; compatible with all digital/offset printing technologies |

| Cutting | CNC-guided precision cutting with burr-free edge profiling | Dimensional tolerance ±1mm; edge integrity checks | Minimizes material waste by 18%; ships 100% ready-to-install products |

Capacity & Compliance

Annual Production Capacity: 90,000 metric tons – scalable for projects from 100 to 100,000+ units with 14-day lead times

100% Final Inspection Protocol: Every batch undergoes Dyne testing, UV resistance validation, and dimensional checks before shipment

Supply Chain Resilience: 6 extrusion lines enable 24/7 production with <2% downtime; supports just-in-time delivery for automotive, agriculture, and logistics clients

Total Cost of Ownership Advantage: 20% lower lifetime costs vs. aluminum or PVC alternatives due to UV stability, corrosion resistance, and minimal maintenance requirements

Procurement Manager Insight: Our 6-line extrusion system delivers consistent quality at scale while eliminating supplier bottlenecks. For automotive clients, this means zero defects in dashboard signage; for logistics, 100% weatherproof pallet markers that survive 2+ years in outdoor storage. All sheets ship with full material traceability and SGS test reports.

Industrial Applications & Case Studies

Industrial Applications of Coroplast Sign Boards

EVERPLAST INDUSTRIAL leverages 90,000 tons annual production capacity, 6 automated extrusion lines, and ISO 9001 certification to deliver industrial-grade Coroplast solutions engineered for extreme durability, cost efficiency, and reuse. Our materials feature corona treatment (Dyne >42) for ink adhesion, UV-stabilized virgin polypropylene, and precision surface smoothness—critical for high-stress B2B applications where failure is not an option.

Automotive Industry: Parts Dunnage & Safety Signage

Critical Use Case: Custom-cut dunnage for automotive components, factory floor safety markers, and tooling guides

Material Performance:

4mm virgin PP with 500+ hours UV resistance; Dyne >42 ensures permanent ink adhesion for critical safety labels

200+ kg load capacity without deformation; moisture-proof for wet assembly environments

Cost-Benefit:

35% lower lifetime cost than wood dunnage; reusable 8+ cycles across assembly lines

50% weight reduction vs. metal alternatives, slashing shipping costs

EVERPLAST Edge:

ISO 9001-controlled extrusion ensures zero batch variation for precision-cut dunnage with ±0.1mm thickness tolerance

Agriculture: Crop Marking & Reusable Crates

Critical Use Case: Field signage for crop identification, reusable vegetable transport crates, irrigation markers

Material Performance:

Waterproof 3-5mm sheets with 2+ growing seasons of UV stability; no cracking in -20°C to 60°C conditions

Smooth surface prevents soil adhesion; easy-to-clean for repeated use

Cost-Benefit:

40% lighter than wood crates; reduces shipping costs by 25% and eliminates single-use packaging waste

30% lower maintenance costs vs. metal alternatives in humid field conditions

EVERPLAST Edge:

6 extrusion lines maintain consistent thickness for stackable crate designs with 99.8% dimensional accuracy

Construction: Floor Protection & Site Signage

Critical Use Case: Temporary flooring protection during renovations, hazard signage, and concrete formwork liners

Material Performance:

4mm thickness resists punctures from nails, tools, and heavy equipment; smooth surface prevents debris adhesion

Waterproof for wet concrete environments; UV-stable for 12+ months of outdoor exposure

Cost-Benefit:

50% cost savings vs. disposable tarps; reusable across 5+ construction phases

70% faster installation than plywood due to lightweight, cut-to-size flexibility

EVERPLAST Edge:

90,000-ton capacity enables rapid fulfillment for large-scale projects (15-day lead time for 10,000+ sqm orders)

Logistics: Pallet & Container Labeling

Critical Use Case: High-visibility pallet identifiers, container tracking labels, and warehouse inventory markers

Material Performance:

Weatherproof 3-4mm sheets withstand 100+ days of outdoor exposure; no warping in humidity >90%

Dyne >42 treatment ensures laser-printed barcodes remain scannable through 10+ shipping cycles

Cost-Benefit:

60% lower cost per cycle than paper labels; 10+ reuse cycles for global shipments

20% lighter than rigid plastic alternatives, reducing fuel costs in transit

EVERPLAST Edge:

Standardized 122x244cm panels with exact tolerances for automated labeling systems; global logistics support

Industrial Application Summary Table

| Application | Material Thickness | UV Resistance | Reusability Cycles | Cost Savings vs. Alternatives | EVERPLAST Advantage |

|---|---|---|---|---|---|

| Automotive Dunnage | 4mm | 500+ hours | 8+ | 35% | ISO 9001-certified precision cutting (±0.1mm tolerance) |

| Agriculture Crates | 3-5mm | 2+ seasons | 3+ | 40% | Consistent thickness via 6 extrusion lines (99.8% dimensional accuracy) |

| Construction Floor | 4mm | 1 year | 5+ | 50% | Bulk order fulfillment in 15 days (10,000+ sqm capacity) |

| Logistics Labels | 3-4mm | 100+ days | 10+ | 60% | Global supply chain support with standardized 122x244cm panels |

Why EVERPLAST?

As a China-based manufacturer since 2009, we eliminate middlemen with factory-direct pricing and zero MOQ for standard sizes. Our 90,000-ton capacity ensures uninterrupted supply for multi-year contracts, while ISO 9001 processes guarantee defect rates <0.2%—critical for industries where downtime costs exceed $10,000/hour. Request a free material sample with Dyne test report today.

Why Global Buyers Choose Everplast

Why Partner with EVERPLAST INDUSTRIAL?

Factory Direct Pricing with Unmatched Scale

90,000 Tons Annual Capacity: 6 ISO 9001-certified extrusion lines ensure consistent supply for large-scale projects

15-25% Cost Savings: Eliminate trading company markups through direct factory pricing

Zero Hidden Fees: Transparent pricing with no tooling charges for custom sizes

Agile Delivery with Risk-Mitigated Terms

7-10 Day Lead Time: Standard orders shipped within 1 week of deposit confirmation

Secure Payment Terms: 30% deposit, 70% balance against shipping documents (B/L copy)

Real-Time Tracking: Live production updates via our ERP system for full supply chain visibility

Technical Excellence Engineered for Performance

Corona Treatment >42 Dyne: Optimized for high-quality digital printing and lamination adhesion

5+ Year UV Resistance: 100% virgin polypropylene with UV stabilizers for prolonged outdoor use

Surface Smoothness ≤0.5μm Ra: Precision-engineered for razor-sharp graphics and consistent ink absorption

Customizable Specifications: Thickness 3-5mm, sizes up to 2440x1220mm, with bespoke color matching

Technical Comparison Table

| Specification | EVERPLAST Standard | Industry Average | Impact on Your Project |

|---|---|---|---|

| Corona Treatment | >42 Dyne | 30-35 Dyne | 20% higher print adhesion; 15% less ink waste |

| UV Resistance | 5+ years | 2-3 years | 50% lower replacement costs over 5-year lifecycle |

| Material Purity | 100% Virgin PP | Up to 30% Recycled | Zero color variation, consistent structural integrity |

| Surface Smoothness | ≤0.5μm Ra | 1.0-2.0μm Ra | Crisp, high-resolution graphics for professional signage |

Ready to Optimize Your Sourcing?

Contact us today for a free custom sample and competitive quotation. Our engineering team will tailor solutions to your exact specifications.

📧 Email: [email protected]

📞 Phone: +86-532-8888-1234

🌐 Website: www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.