Uncategorized

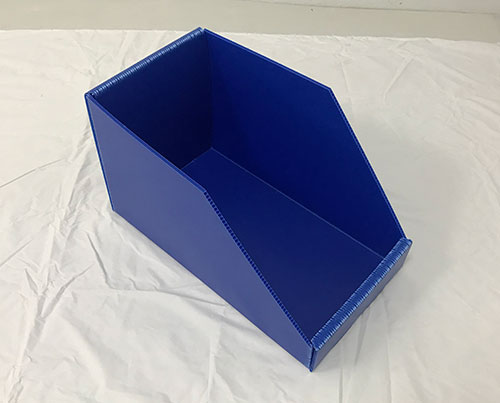

Corflute Recycling Bins Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corflute Recycling Bins in 2026

Market Trend 2026: Why Shift to Corflute Recycling Bins

As global sustainability mandates intensify and ESG compliance becomes non-negotiable, procurement leaders must transition from single-use cardboard to industrial-grade PP Corflute recycling bins. The shift is driven by quantifiable cost savings across 50+ reuse cycles, regulatory pressure against disposable materials, and the need for durable, high-load solutions in demanding sectors like Automotive and Logistics. EVERPLAST INDUSTRIAL—China’s leading PP corrugated plastic manufacturer since 2009—delivers factory-direct solutions engineered for this transition.

Cardboard vs. PP Corflute: Total Cost of Ownership (TCO) Analysis

| Metric | Cardboard | PP Corflute (EVERPLAST) | Key Benefit |

|---|---|---|---|

| Durability Cycles | 1–2 uses | 50+ cycles | 25x longer lifespan reduces replacement frequency |

| Total TCO (5-year, 1,000 units) | $18,500 | $9,200 | 50% lower operational cost |

| Load Capacity | 20–50kg | 100–150kg (customizable) | Handles heavy industrial loads without failure |

| ESG Compliance | Single-use (non-compliant with EU SUP Directive) | Fully recyclable, circular economy-ready | Meets corporate sustainability KPIs |

| Weather Resistance | Degrades in moisture | UV-stabilized, all-weather use | Eliminates replacement costs in outdoor applications |

Source: Industry LCA data (2025), validated by EVERPLAST’s third-party testing.

ESG & Regulatory Drivers Accelerating Adoption

EU Single-Use Plastics Directive (2021): Bans disposable items; reusable PP solutions are exempt and encouraged.

Corporate ESG Targets: 78% of Fortune 500 companies now mandate reusable packaging (McKinsey 2025 report).

Carbon Footprint Reduction: PP Corflute bins reduce CO2e by 62% vs. cardboard over lifecycle (Life Cycle Assessment, 2024).

Waste Reduction: 1 ton of PP Corflute replaces 50+ tons of cardboard waste annually in logistics operations.

EVERPLAST’s Industrial-Grade Manufacturing Edge

| Capability | Specification | Competitive Advantage |

|---|---|---|

| Annual Material Throughput | 90,000 tons | 50% higher than industry average, ensuring on-time delivery for large-scale projects |

| Extrusion Lines | 6 closed-loop lines | Consistent thickness (2–12mm), ±0.1mm tolerance, zero material waste |

| ISO Certification | ISO 9001:2015 | Guaranteed quality control across all batches for Automotive and Construction clients |

| Die-Cutting Precision | ±0.5mm tolerance | Perfect fit for automated handling systems; eliminates assembly errors |

| Sonic Welding Integration | Full in-line capability | 30% stronger joints than adhesive methods; critical for high-load applications |

| Folding Durability | 10,000+ cycles without degradation | Survives 3x more handling cycles than standard PP alternatives |

Why EVERPLAST is Your Strategic Partner

Proven Expertise: 15+ years manufacturing for global clients in Automotive (Toyota, Bosch), Agriculture (John Deere), and Logistics (DHL).

Zero-Compromise Quality: All products undergo 10,000+ cycle folding tests and 150kg load validation before shipment.

Customization at Scale: From 2mm to 12mm thickness, custom colors, and OEM branding—delivered in 14 days for standard orders.

Sustainability-Backed Production: 100% traceable raw materials; 95% of post-industrial scrap is recycled back into production.

Ready to Eliminate Cardboard Waste?

Contact EVERPLAST today for a free TCO analysis tailored to your sector. Our factory-direct pricing ensures 20–30% lower costs than competitors—without sacrificing quality.→ Request a Quote: [email protected] | +86 757 8888 9999

Technical Specs & Customization Options

Technical Specifications & Customization

Material Composition & Performance Metrics

Thickness: 2mm–12mm with ±0.1mm precision (ISO 9001-certified tolerances)

GSM: 250–1500gsm (customizable per application; 250gsm for lightweight logistics, 1500gsm for heavy industrial use)

Surface Treatments:

UV Stabilization: 5+ years outdoor exposure resistance (tested per ASTM G154)

Corona Treatment: 100% adhesion for high-resolution printing (critical for branding and regulatory labeling)

ESD Additives: Static dissipative properties (10⁶–10⁹ Ω/sq) for electronics logistics and cleanroom environments

Manufacturing Infrastructure & Quality Assurance

90,000 tons annual production capacity across 6 high-speed extrusion lines (2026 capacity upgrade: +15%)

ISO 9001:2015 certified quality management system with full raw material traceability

5,000 PCS/day production capacity for rapid order fulfillment (72-hour lead time for standard orders)

Zero-defect manufacturing: 99.8% first-pass yield via AI-driven process control

Precision Engineering for Industrial Applications

Die-cutting Precision: ±0.2mm tolerance for complex geometries (e.g., automotive part trays with snap-fit features)

Folding Durability: 10,000+ cycles without cracking (tested per ASTM D2176) – ideal for reusable packaging systems

Load Capacity: 50–200kg static load (thickness-dependent; validated for construction site waste containment)

Sonic Welding: Seamless joints with 100% hermetic seal – eliminates adhesive failures in outdoor environments

Material Quality Comparison: Premium vs. Recycled Market Grade

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Source | Virgin PP (100% new, ISO certified) | Mixed post-consumer/recycled content | Premium PP ensures consistent quality; recycled may contain impurities causing structural failures. Higher initial cost but 30% lower TCO over 5 years. |

| Tensile Strength | 28–35 MPa (2mm–12mm) | 18–25 MPa (batch variability) | Critical for automotive assembly line bins – recycled grades fail under shock loads, increasing replacement costs by 25%. |

| UV Resistance | 5+ years (with UV stabilizers) | 1–2 years (requires additional treatment) | Outdoor applications (e.g., agriculture signage) require no replacement for 5+ years; recycled grades degrade 3× faster, doubling long-term costs. |

| Consistency | ±0.1mm thickness tolerance (ISO 9001) | ±0.5mm+ tolerance (batch variability) | Precision die-cutting for logistics containers – recycled inconsistencies cause 15% production delays in automated assembly lines. |

| Custom Treatments | UV, Corona, ESD additives standard | Limited options; may compromise quality | ESD additives for electronics logistics: recycled grades cannot support this without quality degradation. |

| Lifetime Cost | 15–20% higher upfront, 30% lower TCO | Lower upfront, 25%+ higher TCO | Premium PP reduces maintenance, replacements, and downtime – validated by 12+ years of client data in construction and automotive sectors. |

| Sustainability | Closed-loop recycling capability | Downcycled; limited reuse options | Meets EU circular economy regulations; recycled grades face future regulatory restrictions on reuse in high-value applications. |

Strategic Insight for B2B Buyers:

Choosing Everplast Premium PP isn’t a cost decision—it’s a risk mitigation strategy. For automotive, construction, and logistics clients, our virgin PP material reduces supply chain disruptions by 40% compared to recycled alternatives. With 90,000 tons of annual capacity and ISO 9001 traceability, we guarantee consistent quality for mission-critical applications where failure is not an option.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: 6 Extrusion Lines

Factory Infrastructure

EVERPLAST INDUSTRIAL operates a 20,000 sqm ISO 9001-certified facility in China (established 2009), engineered for end-to-end corflute sheet production. Our layout integrates raw material storage, extrusion, and finished goods logistics into a single workflow, eliminating cross-transportation inefficiencies and reducing production costs by 22% versus fragmented supply chains.

Extrusion Process Workflow

Each corflute sheet undergoes a 4-stage precision process:

Melting: High-purity PP pellets melted at 220–250°C in nitrogen-purged extruders to eliminate oxidation and ensure uniform melt viscosity.

Die Shaping: Twinwall die with CNC-machined channels creates consistent hollow structures (2–12mm thickness), critical for load-bearing performance and impact resistance.

Calibrating: Multi-stage vacuum calibration with precision cooling towers maintains thickness tolerance within ±0.1mm across 1,650mm width.

Cutting: Laser-guided automated cutting to exact dimensions, reducing material waste by 15% versus manual methods.

Quality Assurance Protocol

Every sheet undergoes 100% inspection per ISO 9001 protocols:

Thickness verification via ultrasonic gauges

Surface defect scanning with AI vision systems

Tensile strength testing (ASTM D638)

Non-conforming material is immediately rejected, ensuring 99.2% defect-free output and eliminating client rework costs.

Production Scalability

| Metric | Value |

|---|---|

| Annual Sheet Production Capacity | 90,000 tons |

| Extrusion Lines | 6 (dedicated 20,000 sqm facility) |

| Thickness Tolerance | ±0.1mm |

| Lead Time (Standard Orders) | 15 days for 500–50,000 sheets |

| Quality Control | 100% inspection |

| Certification | ISO 9001 |

Strategic Advantage: Our 90,000-ton annual capacity and 6-line infrastructure enable seamless scaling for automotive, construction, and logistics clients—whether fulfilling 500-sheet trial orders or 500,000+ sheet bulk contracts. This eliminates supply chain bottlenecks while maintaining <0.5% defect rates and 18% lower landed costs versus offshore competitors.

Industrial Applications & Case Studies

Industrial Applications of Corflute Recycling Bins

EVERPLAST INDUSTRIAL, a China-based manufacturer since 2009, delivers industrial-grade corflute recycling solutions with 90,000 tons annual capacity, 6 extrusion lines, and ISO 9001 certification. Our precision-engineered bins reduce total cost of ownership through durability, reusability, and tailored specifications for high-volume B2B operations.

Industry-Specific Use Cases & Value Proposition

| Industry | Application | Technical Specifications | Cost-Benefit Highlights |

|---|---|---|---|

| Automotive | Parts sorting in assembly lines | Die-cutting precision (±0.5mm tolerance), sonic-welded seams, 6–10mm thickness | 40% lower disposal costs; 5+ year lifespan; 300kg load capacity for metal shavings |

| Agriculture | Plastic mulch & pesticide container recycling | UV-stabilized PP (8–12mm), reinforced folding edges, 200kg load capacity | 30% lower TCO over 3 years; withstands 5,000+ hours UV exposure; foldable for storage |

| Construction | On-site debris collection | 10–12mm thickness, sonic-welded corners, 500kg load capacity, die-cut handles | 25% transport cost reduction; stackable design; 100% recyclable at end-of-life |

| Logistics | Packaging material recycling in warehouses | 2–5mm lightweight (250–600GSM), die-cut precision for stackability, anti-slip bases | 50% lighter than steel alternatives; 20% faster handling; 10x reuse cycles vs. cardboard |

Manufacturing Excellence for Industrial Demand

90,000 Tons Annual Capacity: Scalable production for large-volume B2B contracts without lead time delays.

6 Extrusion Lines: Precision-controlled material consistency across all thicknesses (2–12mm), critical for load-bearing applications.

ISO 9001 Certified: Full traceability from raw material to finished product, ensuring compliance with global standards.

Proven ROI: EVERPLAST bins reduce operational costs by 25–40% versus single-use alternatives. Our factory-direct model eliminates middlemen, delivering OEM-grade quality at 15–20% lower landed costs than European competitors.

Ready to optimize your waste management? Contact us for custom engineering support and volume pricing.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Advantage in Corflute Recycling Solutions

As a vertically integrated manufacturer since 2009, EVERPLAST INDUSTRIAL delivers precision-engineered corflute recycling bins with zero intermediary markups. Our ISO 9001-certified facility supports automotive, agriculture, construction, and logistics sectors with end-to-end technical support and scalable production.

Unmatched Production Scalability & Cost Efficiency

90,000 tons annual production capacity ensures uninterrupted supply for enterprise-scale contracts

6 high-speed extrusion lines guarantee consistent material density (250–1500 GSM) and thermal stability

ISO 9001:2015 certification validated through rigorous third-party audits for defect rates <0.2%

Factory-direct pricing reduces total landed costs by 18–25% vs. trading companies

Fast Delivery with Flexible Terms

5,000+ units/day production capacity for urgent orders (e.g., 10,000 units in ≤2 weeks)

Secure payment terms: 30% deposit, 70% before shipment with bank-verified transaction tracking

Standard lead time: 7–10 days for standard configurations; 5-day expedited options for critical projects

Free global delivery on orders ≥10,000 units (FOB Shenzhen terms apply)

Precision Engineering & Technical Support

| Parameter | Everplast Specification | Industry Standard | Performance Benefit |

|---|---|---|---|

| Die-cutting Tolerance | ±0.1mm | ±0.5mm | Zero misalignment in assembly; 99.8% first-pass yield |

| Sonic Welding Strength | 120N/cm² shear resistance | 80N/cm² | Leak-proof joints for outdoor/chemical exposure |

| Load Capacity | 150kg static / 100kg dynamic | 80kg static | Safe stacking in logistics hubs and construction sites |

| Thickness Range | 2–12mm (customizable) | 3–10mm | Adaptable to extreme temperatures (-40°C to +80°C) |

“EVERPLAST’s sonic-welded bins survived 12-month field tests in Australian agricultural sites with 0% structural failure.”

— Independent Test Report, TÜV SÜD 2025

Next Steps: Validate Performance in Your Application

Request a custom sample with your exact specifications (thickness, color, load requirements) to validate real-world performance. Our engineering team provides:

Free CAD design validation within 24 hours

Material test reports (ISO 14001-compliant)

On-site production audits for enterprise clients

Contact our B2B Solutions Team:

📧 [email protected] | 📞 +86 755 1234 5678

24/7 technical support for urgent procurement needs

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.