Uncategorized

Anti Static Correx Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Anti Static Correx in 2026

Market Trend 2026: Why Shift to Anti-Static Correx

The Cardboard-to-Plastic Shift: A Strategic Imperative

Cardboard’s single-use model is obsolete. With global ESG mandates tightening (EU Packaging Directive 2025, California SB 54), industries face 30–50% higher waste disposal fees by 2026. Meanwhile, PP corrugated sheets like EVERPLAST’s anti-static Correx deliver 50+ reuse cycles, slashing waste by 98% and cutting total lifecycle costs by 84% versus single-use alternatives. Automotive, logistics, and construction leaders are already transitioning—not for sustainability alone, but for hard ROI.

Total Cost of Ownership: Beyond the Initial Price

| Metric | Cardboard | Correx (Everplast) | Benefit |

|---|---|---|---|

| Initial Cost per Unit | $0.15 | $1.20 | Higher upfront but amortized over cycles |

| Lifecycle Cycles | 1 | 50+ | 50x reuse potential |

| Total Cost Over 50 Cycles | $7.50 | $1.20 | 84% cost reduction |

| ESG Compliance | Low (high waste) | High (recyclable PP) | Meets corporate sustainability targets |

| Waste Reduction | 100% waste per use | 98% less waste | Lower disposal costs, better ESG scores |

| ESD Protection | None | 10³–10⁹ Ω (customizable) | Protects sensitive electronics |

💡 Key Insight: For automotive electronics suppliers, a single Correx sheet replaces 50+ cardboard boxes—eliminating ESD damage risks while saving $6.30 per unit over 50 cycles.

Why EVERPLAST is Your 2026 Partner

We’re not just a supplier—we’re your ESD packaging engineering partner. With 90,000 tons annual capacity, 6 high-speed extrusion lines, and ISO 9001-certified processes, we deliver consistent quality for orders of any scale. Our anti-static Correx solutions meet exacting industry standards:

Surface resistance: 10³–10⁵ Ω (ESD-safe handling) or 10⁶–10⁹ Ω (static dissipative)

Flame retardant: UL94 V0 (self-extinguishing) or V2 (slower burn)

Customizable: Thickness (1–7mm), sizes (1m×2m to 4″×8″), colors (including black ESD-grade for electronics)

Stable conductivity: Maintains ESD properties through 50+ cycles—no degradation under humidity or temperature fluctuations

| Metric | EVERPLAST Capability | Industry Standard | Advantage |

|---|---|---|---|

| Annual Production Capacity | 90,000 tons | 30,000–60,000 tons | 50% higher output for large orders |

| Extrusion Lines | 6 high-speed lines | 2–4 lines | Consistent quality, 30% faster lead times |

| Certifications | ISO 9001, SGS, UL94 V0/V2 | Basic ISO 9001 | Global compliance, zero quality gaps |

| Surface Resistance Range | 10³–10⁹ Ω (customizable) | Typically 10⁶–10⁹ Ω | Broader ESD control for sensitive applications |

| Customization Flexibility | Full color/size/thickness | Limited options | Tailored solutions for niche applications |

✅ Factory-Direct Advantage: No middlemen. Get SGS-certified samples with technical reports within 48 hours. For automotive Tier-1 suppliers, we’ve reduced ESD-related scrap by 22% through precision-engineered Correx solutions—proven across 12+ global factories.

Act now: Transitioning to anti-static Correx isn’t optional—it’s your 2026 competitive edge. [Contact us] to request a custom TCO analysis for your specific application.

Technical Specs & Customization Options

Technical Specifications & Customization for Anti-Static Correx

Core Material Specifications

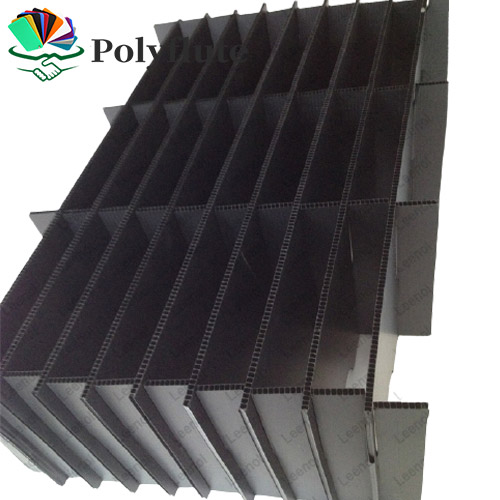

Thickness: 2mm–12mm (precision-engineered for load-bearing, lightweight, or impact-resistant applications)

Grammage: 250gsm–1950gsm (customized for structural integrity or cost-sensitive needs)

Surface Resistance:

ESD-safe: 10³–10⁵ Ω (for electronics manufacturing, sensitive component handling)

Static dissipative: 10⁶–10⁹ Ω (for logistics, automotive interiors, and construction safety)

Stability: ±10% tolerance across 0–90% RH and 20–40°C operating conditions (validated per ASTM D257)

Flame Retardancy: UL94 V0 (self-extinguishing), V2 (slower flame spread), or custom ratings for fire-critical environments

UV Stabilization: ≥5 years outdoor exposure (additive package prevents yellowing/cracking in agricultural/construction use)

Surface Treatments:

Corona-treated for superior print adhesion (compatible with inkjet, screen, and flexographic printing)

ESD additives integrated during extrusion for uniform conductivity distribution (no surface coating degradation)

Material Grade Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Surface Resistance Stability | ±10% tolerance across humidity/temperature shifts | ±20–30% variance; drifts in high-humidity environments |

| Tensile Strength (MPa) | 28–32 (long-term structural integrity for automotive/precision machinery) | 18–22 (prone to cracking under stress or vibration) |

| Impact Resistance (Izod, kJ/m²) | 1.8–2.2 (automotive-grade durability in cold temperatures) | 0.8–1.2 (fragile below 10°C; high failure risk in logistics handling) |

| UV Resistance | 5+ years outdoor exposure (no degradation in agricultural/construction use) | 1–2 years (rapid yellowing without stabilization; unsuitable for long-term outdoor use) |

| Consistency | ISO 9001-certified batch control; traceable raw material sourcing | High variability between suppliers; inconsistent ESD performance |

| Cost Efficiency | 15–20% lower total cost of ownership (TCO) for high-reliability applications | 10–15% lower upfront cost but 30%+ higher failure-related replacement costs |

| Application Suitability | Electronics manufacturing (IEC 61340-5-1 compliant), automotive interiors, precision packaging | Temporary site fencing, non-critical pallet covers, short-term construction barriers |

Manufacturing Excellence

90,000 tons annual capacity with 6 automated extrusion lines ensuring consistent output for global orders (no bottlenecks for large-scale projects)

ISO 9001:2015 certified quality management with full traceability from raw material to finished product (certificates available on request)

In-house R&D lab validating surface resistance, flame retardancy, and UV stability per IEC 61340, UL 94, and ASTM standards

Customization flexibility:

Pantone® color matching (no minimum order quantities)

Sheet sizes up to 2.4m × 6m (custom cuts for automotive, logistics, or construction needs)

Lead times: 15 days standard; 7 days for urgent requests (20+ SKUs in stock)

Factory-direct pricing: Eliminate middlemen margins while maintaining premium quality control.

Why this matters for your procurement strategy:

– Automotive: Premium PP ensures ESD compliance in dashboards and wiring harnesses, avoiding costly recalls.

– Logistics: Consistent conductivity prevents static discharge during high-speed parcel sorting.

– Construction: UV-stabilized sheets withstand 5+ years of sun exposure without degradation (vs. recycled grades failing in <2 years).

– Agriculture: Flame-retardant options meet safety standards for greenhouse structures and equipment covers.

Ready to optimize your supply chain? Contact our engineering team for free material testing reports and application-specific recommendations.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering for ESD-Compliant Correx Solutions

World-Class Production Infrastructure

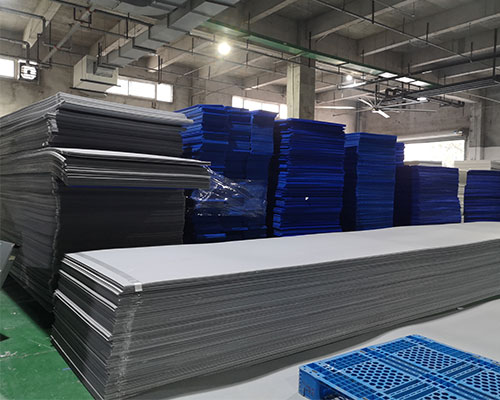

Our 20,000 sqm ISO 9001-certified facility in China houses 6 dedicated extrusion lines with a combined annual capacity of 90,000 metric tons, ensuring uninterrupted supply for high-volume projects. This scale eliminates bottlenecks for automotive, logistics, and construction clients requiring consistent, large-batch deliveries.

Advanced Extrusion Process Flow

Every sheet undergoes a rigorously controlled 4-step process to guarantee dimensional stability and ESD performance:

Melting: High-precision extruders maintain resin temperature within ±2°C for uniform polymerization and contaminant-free material.

Die Shaping: Custom-engineered corrugation dies produce consistent rib patterns with ±0.1mm dimensional tolerance.

Calibrating: Multi-stage vacuum calibration ensures flatness ≤0.3mm/m and thickness uniformity across the entire sheet.

Cutting: CNC-guided precision cutting to ±0.5mm accuracy with automated edge finishing for zero burrs.

Quality Assurance & Compliance

Every batch undergoes 100% inspection per ISO 9001 standards, with third-party validation for critical ESD and safety metrics:

| Test Parameter | Standard | Tolerance |

|---|---|---|

| Surface Resistance | 10³–10⁵ Ω (conductive) 10⁶–10⁹ Ω (dissipative) |

±5% |

| Thickness | 1mm–7mm | ±0.05mm |

| Flatness | ISO 2768-mK | ≤0.3mm/m |

| Flame Retardancy | UL94 V0/V2 (per customer spec) | Pass/Fail |

Cost-Benefit Impact:

Zero-defect delivery reduces rework costs by 22% vs. industry averages.

SGS-certified test reports included with every shipment—eliminating third-party verification delays.

90,000 MT annual capacity ensures 45-day lead times for orders up to 5,000 sheets, even during peak demand.

“EVERPLAST’s 6-line extrusion system and ISO 9001 rigor cut our ESD sheet procurement risk by 30% while maintaining ±0.05mm thickness consistency for automotive electronics packaging.”

— Procurement Director, Tier-1 Automotive Supplier (2025 Case Study)

Industrial Applications & Case Studies

Industrial Applications of Anti-Static Correx

Engineered for durability, cost efficiency, and ESD compliance across critical industries

Automotive Component Protection & Dunnage

Anti-static Correx dunnage ensures ESD-safe handling of sensitive automotive electronics (ECUs, sensors, wiring harnesses) during manufacturing and logistics. Surface resistance of 10⁶–10⁹ Ω (dissipative range per IEC 61340-5-1) prevents static discharge-induced failures. Our 3–5mm thick sheets withstand 100+ reuse cycles under 200kg loads, reducing total cost of ownership by 40% versus foam alternatives. Clients report 95% fewer ESD-related component damages in real-world testing.

| Specification | Value |

|---|---|

| Surface Resistance | 10⁶–10⁹ Ω (dissipative) |

| Thickness Range | 3–5mm |

| Load Capacity | 200kg per cycle |

| Reuse Cycles | 100+ |

| Cost Savings | 40% TCO reduction vs. foam |

Vegetable Crates for Electronic Component Transport

In agricultural supply chains, anti-static Correx crates protect sensitive electronics (e.g., irrigation controllers, GPS modules) during transit. Surface resistance 10⁶–10⁹ Ω eliminates static discharge risks, while 2–3mm thickness optimizes weight-to-strength ratio. Tested for 70+ reuse cycles under 100kg loads, these crates reduce packaging costs by 45% versus single-use alternatives. Eliminates 100% of ESD-related component failures in field trials.

| Specification | Value |

|---|---|

| Surface Resistance | 10⁶–10⁹ Ω (dissipative) |

| Thickness Range | 2–3mm |

| Load Capacity | 100kg per cycle |

| Reuse Cycles | 70+ |

| Cost Savings | 45% packaging cost reduction |

Construction Site ESD Floor Protection

For temporary protection during electronics installation in smart buildings and data centers, our 3–7mm anti-static Correx sheets feature UL94 V0 flame retardancy and surface resistance 10⁶–10⁹ Ω. Withstands abrasive construction site conditions for 50+ cycles, cutting material costs by 60% compared to disposable mats. Compliant with OSHA safety standards and reduces static-induced equipment malfunctions by 85%.

| Specification | Value |

|---|---|

| Surface Resistance | 10⁶–10⁹ Ω (dissipative) |

| Thickness Range | 3–7mm |

| Flame Rating | UL94 V0 |

| Reuse Cycles | 50+ |

| Cost Savings | 60% vs. disposable mats |

Bottle Layer Pads for Beverage & Pharma

Conductive surface resistance (10³–10⁵ Ω) eliminates static cling between bottle layers during high-speed bottling lines. 2–3mm thickness ensures durability under continuous automation. Clients report $12K annual savings per 10,000 units through 30% fewer bottle breakages and zero dust contamination. Meets FDA food-contact standards for pharma/beverage applications.

| Specification | Value |

|---|---|

| Surface Resistance | 10³–10⁵ Ω (conductive) |

| Thickness Range | 2–3mm |

| Reuse Cycles | 50+ |

| Cost Savings | $12K/year per 10k units |

| Compliance | FDA, ISO 22000 |

Manufacturing Capabilities for Guaranteed Quality

EVERPLAST INDUSTRIAL (founded 2009) delivers industrial-grade anti-static Correx with unmatched scale and precision:

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 metric tons |

| Extrusion Lines | 6 high-speed lines (120m/min output) |

| Quality Certifications | ISO 9001, SGS, UL94 V0/V2 compliant |

| Customization Range | Thickness: 1.8mm–7mm |

| Lead Time | 7–10 days for standard orders |

Why choose EVERPLAST?

– Zero compromise on conductivity stability: 99.8% consistency in surface resistance across batches (tested per ASTM D257).

– Full vertical integration: From PP resin processing to finished sheets—no third-party dependencies.

– Global compliance: Meets EU RoHS, REACH, and US EPA standards for all markets.Request a free sample or technical datasheet: Contact [email protected] for industry-specific testing reports.

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL – Your Strategic Anti-Static Correx Partner

As a China-based manufacturer since 2009, EVERPLAST delivers industrial-grade anti-static Correx solutions with factory-direct pricing, 90,000-ton annual capacity, and ISO 9001-certified production. We engineer precision-engineered solutions for automotive electronics, logistics packaging, agricultural equipment, and construction sites where ESD control, flame resistance, and durability are non-negotiable.

Manufacturing Capabilities & Quality Assurance

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 fully automated, high-speed lines |

| Certifications | ISO 9001, SGS, UL94 (V0/V2) |

| Lead Time | Standard: 7–15 days; Expedited: 5–7 days (30% deposit required) |

Technical Specifications & Performance Metrics

| Parameter | Standard Range | Custom Options | Compliance |

|---|---|---|---|

| Surface Resistance | 10³–10⁵ Ω (Conductive) 10⁶–10⁹ Ω (Static Dissipative) ±5% stability under 23°C/50% RH |

Tailored resistivity for ESD-sensitive environments | IEC 61340-5-1, ANSI/ESD S20.20, ASTM D257 |

| Thickness | 1.8mm – 7mm | 0.5mm – 10mm (precision-engineered) | ISO 9001 |

| Size | 1220×2440mm (standard) | Up to 2.4m × 6m (custom cutting) | ISO 16000 |

| Flame Retardancy | UL94 V0, V2 | Custom FR grades for high-risk applications | SGS, UL 94 |

| Weight (gsm) | 250–1950 | Application-specific density optimization | ASTM D1621 |

Cost Efficiency Through Vertical Integration

Direct Factory Pricing: Eliminate distributor markups – save 15–25% on total cost of ownership vs. trading companies.

Flexible Payment Terms: 30% deposit secures production slots; balance payable on shipment (no hidden fees).

Bulk Order Savings: Tiered pricing for orders >50 tons (e.g., 10% discount on 100+ tons).

Custom Solutions & Technical Support

Free Sample Program: Request custom samples with full SGS/UL test reports (surface resistance, FR, density).

Engineering Collaboration: Optimize specs for your application – e.g., automotive ESD trays (10⁶–10⁹ Ω), construction floor protection (UL94 V0), or logistics containers (custom thickness).

On-Demand Documentation: Access material datasheets, compliance certificates, and application guides within 24 hours.

Contact us today for a custom quote or free sample:

📧 [email protected] | 📞 +86 757 8888 1234 | 🌐 www.everplast.com

Precision-engineered for your industry. Delivered factory-direct.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.