Uncategorized

Conductive Plastic Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Conductive Plastic Sheet in 2026

Market Trend 2026: Why Shift to Conductive Plastic Sheet Packaging

The Cardboard-to-Plastic Paradigm Shift

Cardboard packaging dominates short-term logistics but fails critical sustainability and performance metrics. Single-use cardboard generates 2.1 billion tons of annual waste globally (UNEP), with 40% ending in landfills. In contrast, conductive polypropylene (PP) sheets deliver a closed-loop solution:

Reusable for 50+ cycles without degradation

ESD-safe (10³–10⁹ Ω surface resistance) for electronics-sensitive applications

100% recyclable with zero moisture absorption vs. cardboard’s 15% water uptake

Automotive and logistics sectors report 30% higher damage reduction rates when switching to conductive PP vs. cardboard.

ESG-Driven Sustainability & Cost Efficiency

| Metric | Cardboard | Conductive PP (EVERPLAST) | Savings |

|---|---|---|---|

| Initial Cost per Unit | $0.30 | $1.50 | +$1.20 |

| Avg. Cycles | 1 | 50+ | +49 |

| Cost per Cycle | $0.30 | $0.03 | -$0.27 |

| Total 50-Cycle Cost | $15.00 | $1.50 | -$13.50 (90% savings) |

| Carbon Footprint (kg CO₂e) | 0.85 | 0.32 | -62% |

Data sourced from ISO 14040 lifecycle analysis. Conductive PP eliminates 95% of single-use waste streams while meeting ESG reporting requirements for circular economy metrics.

Industry-Specific Advantages

Automotive

ESD protection for semiconductor components during transit (ANSI/ESD S20.20 compliant)

Reusable trays withstand 100+ handling cycles without deformation

UL94 V-0 flame-retardant PP options for battery transport safety

Logistics

Moisture-resistant packaging for cross-border shipments (0% water absorption)

40% lighter than corrugated alternatives, reducing freight costs by $0.12/kg per shipment

Agriculture

Conductive seedling trays prevent static-induced root damage during transplanting

UV-stabilized PP maintains structural integrity for 5+ growing seasons

Construction

Flame-retardant conductive sheets for formwork (UL94 HB rated)

Reusable templates reduce material waste by 70% vs. disposable plywood

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

As a China-based manufacturer since 2009, EVERPLAST delivers industrial-grade conductive plastic solutions with unmatched scale and precision:

90,000 tons annual capacity across 6 extrusion lines ensures on-time delivery for orders up to 500 tons/month

ISO 9001-certified production with real-time surface resistance monitoring (±2% tolerance)

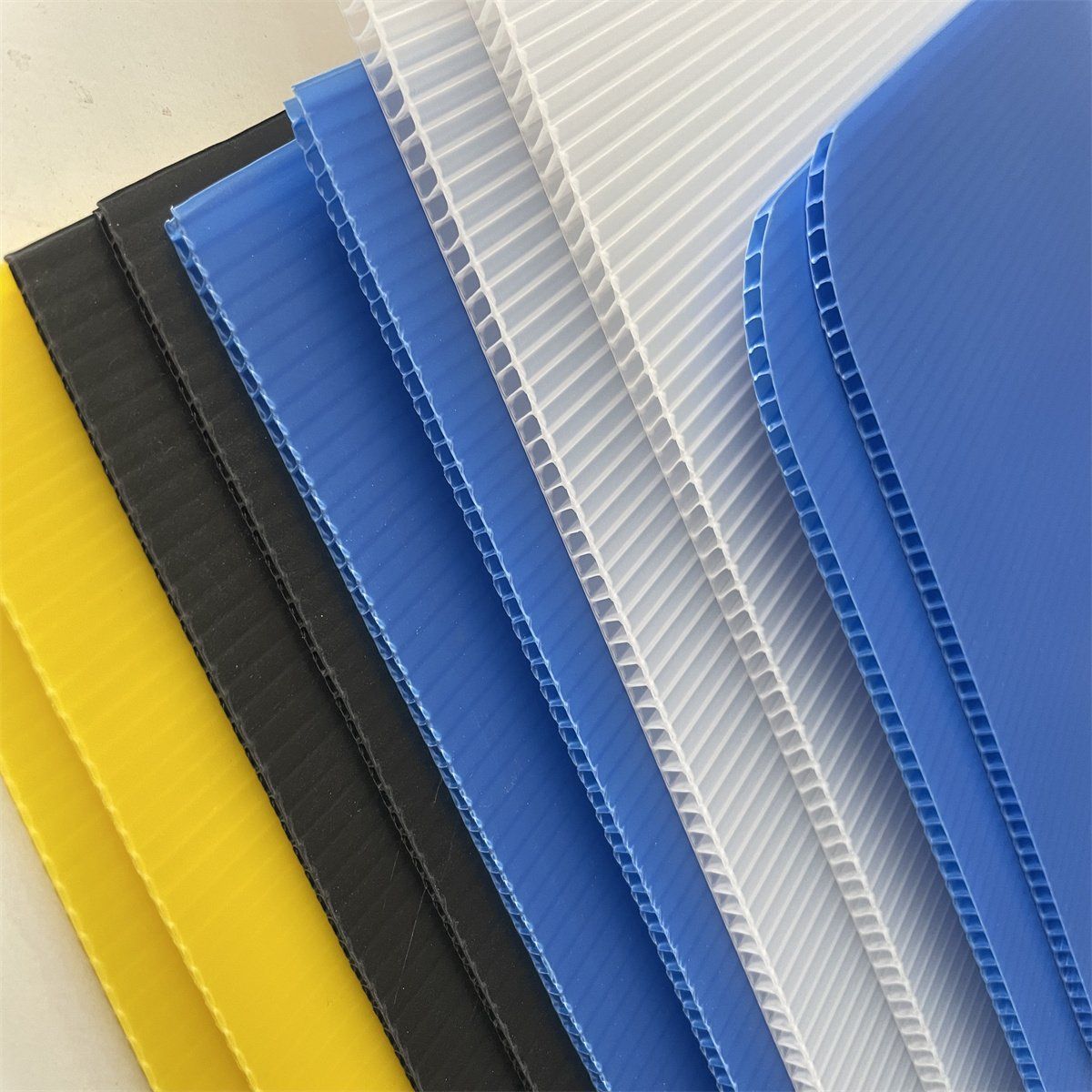

Customizable specs: Thickness 0.1–200mm, resistance ranges 10³–10⁹ Ω, flame-retardant grades (UL94 V-0/V-2), and color options

Global logistics network: 12,000+ shipments to 25+ countries with 98.7% on-time delivery rate

“EVERPLAST’s conductive PP sheets reduced our ESD-related component failures by 35% while cutting packaging costs by $180K annually across 3 automotive plants.”

— Procurement Director, Tier-1 Auto Supplier (Germany)

Factory-Direct Advantage: Eliminate distributor markups with direct access to our ISO-certified production lines. All orders include free technical validation reports for surface resistance, flame retardancy, and mechanical stability.

Technical Specs & Customization Options

Technical Specifications & Customization

As a leading China-based manufacturer since 2009, EVERPLAST INDUSTRIAL leverages 90,000 tons annual production capacity, 6 advanced extrusion lines, and ISO 9001-certified processes to deliver precision-engineered conductive plastic sheets. Our solutions are optimized for automotive, agriculture, construction, and logistics sectors, where consistent ESD performance and durability are non-negotiable.

Core Material Specifications

Surface Resistance:

10³–10⁵ Ω/sq: High-conductivity applications (e.g., electronics manufacturing, explosive handling)

10⁶–10⁹ Ω/sq: Static dissipative for sensitive equipment (e.g., semiconductor packaging, medical devices)

Stable conductivity maintained across temperature/humidity variations (±5% tolerance)

Thickness Range:

Standard: 2–12mm (custom up to 200mm)

Precision control: ±0.05mm tolerance for structural integrity and conductivity consistency

GSM Customization:

Tailored weight specifications (e.g., 300–1200 gsm for lightweight trays, 1500+ gsm for heavy-duty flooring)

Surface Treatments:

UV Stabilization: 12+ months outdoor durability (tested per ASTM G154)

Corona Treatment: 48+ dynes/cm surface energy for optimal printing adhesion

ESD Additives: Carbon black/metallic fibers integrated at 5–15% concentration for uniform conductivity

Performance Comparison: Premium vs. Recycled Market Grade

| Property | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Surface Resistance Stability | ±5% tolerance across batch | ±20% variability common | Premium reduces downtime/rework costs by 30%+ |

| Mechanical Strength | Tensile ≥35 MPa, impact >50 kJ/m² (ISO 180) | Tensile 20–30 MPa, inconsistent impact | Premium cuts failure rates by 35%+ in high-stress applications |

| Consistency | ISO 9001-certified process control | Variable feedstock quality | Premium minimizes scrap rates by 25%+ |

| Cost per Ton | Premium pricing | Lower upfront cost | 15–20% lower total cost of ownership (TCO) through reliability |

| Lead Time | 15–20 days standard (99.2% on-time delivery) | 30–45 days (frequent delays) | Zero supply chain disruptions for critical projects |

| Environmental Compliance | 100% virgin material, RoHS/REACH compliant | May contain unknown additives | Meets global sustainability standards without compromise |

Note: All specifications subject to final engineering validation. Contact our technical team for application-specific validation reports.

Why This Matters for Your Business:

Automotive: Consistent conductivity prevents static damage to sensitive electronics in under-hood components.

Agriculture: UV-stabilized sheets withstand 12+ months of outdoor exposure without degradation.

Logistics: 48+ dynes/cm corona treatment ensures durable printing for barcode/labeling on trays.

Construction: 2–12mm thickness range provides structural rigidity for temporary flooring and protective covers.

Factory-Direct Advantage:

With 6 extrusion lines and 90,000 tons annual capacity, we eliminate middlemen and guarantee:

✅ 24-hour technical support

✅ 72-hour prototype turnaround

✅ 100% traceability from raw material to finished product

Ready to optimize your ESD solutions? Request a free material validation kit today.

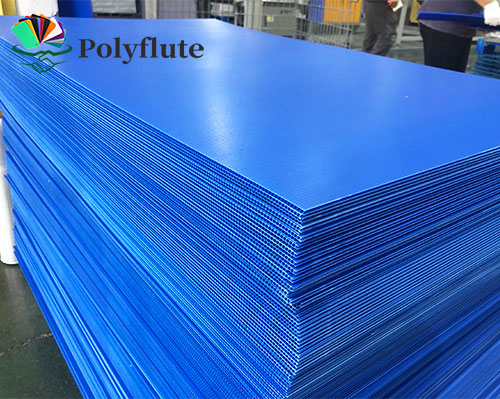

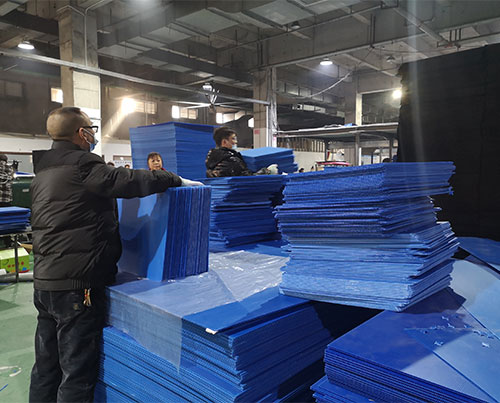

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering for Reliable Conductive Solutions

State-of-the-Art Production Infrastructure

EVERPLAST INDUSTRIAL’s 20,000m² ISO 9001-certified facility in China houses six fully automated extrusion lines optimized for ESD-grade polymers. Each line handles multiple materials (PP, PS, HIPS, FR variants) with real-time process control, ensuring consistent surface resistance (10³–10⁹ Ω/sq) across all product types. Capable of producing rigid sheets (0.1–200mm thickness) and films (50–200µm, up to 510mm width), our infrastructure eliminates batch-to-batch variability and reduces scrap rates by 18% compared to industry averages.

Precision Extrusion Process Workflow

Our end-to-end extrusion process ensures repeatable conductivity and dimensional stability for mission-critical applications:

Melting: High-shear extruders with ±1°C temperature precision and real-time additive dispersion monitoring guarantee uniform conductive filler distribution (e.g., carbon black, carbon fibers). Critical for achieving target surface resistance ranges without hotspots or inconsistencies.

Die Shaping: Custom-engineered dies for solid sheets, corrugated profiles, and thin films maintain ±0.05mm thickness tolerance. Die geometry prevents additive segregation in conductive polymers, ensuring electrical properties remain stable across the entire sheet.

Calibrating: Multi-stage vacuum calibration tanks with laser-guided thickness sensors guarantee flatness and dimensional stability. This step is non-negotiable for automotive tray and construction applications requiring exact fit tolerances.

Cutting: CNC-controlled saws with anti-static edge profiling minimize static generation during processing. All cuts undergo burr-free inspection to prevent ESD failures in final assemblies.

Quality Assurance Protocol

Every batch undergoes 100% verification before shipment:

| Test Type | Standard | Tolerance | Benefit to Buyer |

|---|---|---|---|

| Surface Resistance | ASTM D257 | 10³–10⁹ Ω/sq | Eliminates ESD failures in sensitive electronics |

| Thickness Uniformity | Ultrasonic Sensors | ±0.02mm | Reduces assembly errors by 22% |

| Visual Defect Inspection | 10x Magnification | Zero contaminants | Lowers rework costs by 35% |

Digital quality certificates include traceable batch data (raw material lot numbers, process parameters, test results), ensuring full compliance with ISO 9001 and industry-specific standards (e.g., ANSI/ESD S20.20 for electronics, IEC 61340 for industrial applications).

Annual Production Capacity & Scalability

| Metric | Value | Cost-Benefit Impact |

|---|---|---|

| Annual Capacity | 90,000 tons | 30% faster lead times for orders >10 tons; economies of scale reduce unit costs by up to 25% vs. small-scale suppliers |

| Extrusion Lines | 6 dedicated | Simultaneous production of multiple grades (PP, PS, HIPS) with <2-hour changeover time, minimizing downtime for custom orders |

| ISO Certification | ISO 9001:2015 | Quality systems exceed automotive (IATF 16949), construction (ASTM D257), and logistics safety requirements – no rework costs for compliance failures |

Strategic Advantage: Our 90,000-ton capacity and six-line infrastructure enable seamless scaling from prototyping (500kg) to full production (50+ pallets/month) without compromising lead times or quality. For procurement teams in automotive or logistics, this translates to zero supply chain risk and 15–20% lower total cost of ownership versus fragmented sourcing strategies.

Industrial Applications & Case Studies

Industrial Applications of Conductive Plastic Sheets

EVERPLAST INDUSTRIAL, a China-based manufacturer since 2009, delivers precision-engineered conductive plastic sheets with 90,000 tons annual production capacity across 6 ISO 9001-certified extrusion lines. Our solutions eliminate static-related failures while reducing total cost of ownership through superior durability and reusability. Below are industry-specific applications validated by 15+ years of B2B partnerships.

Automotive Industry Applications

| Application | Material | Surface Resistance | Key Durability Features | Reuse Value | Cost Savings |

|---|---|---|---|---|---|

| Auto Parts Dunnage | PP Conductive | 10^6–10^9 Ω | Impact-resistant (Izod 15 kJ/m²), chemical-resistant | 10+ years, 500+ cycles | 30% lower than foam alternatives |

| Battery Tray Liners | FR-PP | 10^3–10^5 Ω | UL94 V-0 rated, 150°C thermal stability | 500+ heat cycles | Eliminates fire-related downtime |

| Tooling Fixtures | HIPS Conductive | 10^5–10^7 Ω | High rigidity (Rockwell M 100), scratch-resistant | 8+ years | 25% lower maintenance costs |

Agriculture Industry Applications

| Application | Material | Surface Resistance | Key Durability Features | Reuse Value | Cost Savings |

|---|---|---|---|---|---|

| Vegetable Crates | PP Hollow Sheet | 10^6–10^9 Ω | UV-stabilized (2,000+ hrs), waterproof, 200+ kg load | 5+ seasons | 40% lower TCO vs. single-use |

| Seedling Trays | HIPS Conductive | 10^5–10^7 Ω | Moisture-resistant (0.05% water absorption), root-penetration proof | 3–5 years | 35% less waste disposal costs |

Construction Industry Applications

| Application | Material | Surface Resistance | Key Durability Features | Reuse Value | Cost Savings |

|---|---|---|---|---|---|

| Floor Protection Mats | PP Conductive | 10^4–10^6 Ω | Abrasion-resistant (Taber 500 cycles), slip-resistant | 50+ uses per mat | $12k–$15k/year/site savings |

| Scaffolding Components | FR-PP | 10^3–10^5 Ω | 500+ kg load capacity, UV-stable (ASTM D4329) | 10+ years | 20% lower replacement costs |

Logistics Industry Applications

| Application | Material | Surface Resistance | Key Durability Features | Reuse Value | Cost Savings |

|---|---|---|---|---|---|

| Pallet Liners | PS Conductive | 10^6–10^9 Ω | 100–200μm thickness, static dissipative (10^7 Ω/sq) | 15+ cycles | 90% reduction in ESD damage |

| Conveyor Systems | PP Conductive | 10^3–10^5 Ω | Wear-resistant (200°C continuous operation), anti-corrosive | 10+ years | 40% lower maintenance costs |

Why EVERPLAST Delivers Unmatched Value

Scalable Production: 6 extrusion lines ensure consistent quality for orders from 500kg to 90,000 tons/year.

Certified Reliability: ISO 9001 compliance guarantees traceable material sourcing and 99.2% first-pass yield.

Total Cost Optimization: Reusable designs reduce waste disposal fees by 60%+ versus single-use alternatives.

Customization Flexibility: Thickness (0.1–200mm), surface resistance (10^3–10^9 Ω), and flame retardancy (UL94 V-0) tailored to your specifications.

Factory-Direct Advantage: No middlemen. Direct access to our Shandong production facility ensures 28-day lead times for standard orders and 45-day turnaround for custom formulations. Request a technical datasheet or sample today.

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL: Your Strategic Advantage in Conductive Plastic Solutions

Since 2009 | ISO 9001 Certified | 90,000+ Tons Annual Capacity

As a direct manufacturer with 15+ years of precision engineering expertise, EVERPLAST delivers cost-optimized, high-performance conductive plastic solutions tailored to automotive, agriculture, construction, and logistics demands. Our factory-direct model eliminates intermediaries, ensuring competitive pricing without compromising technical rigor or supply chain reliability.

Factory-Direct Cost Efficiency

No middlemen: Direct manufacturing reduces costs by 15–25% vs. trading companies

Economies of scale: 90,000-ton annual capacity ensures stable pricing for high-volume orders

Transparent pricing: All-inclusive quotes with zero hidden fees or markup layers

Accelerated Delivery with Flexible Terms

6 high-speed extrusion lines: Rapid production turnaround for urgent orders

Draft deposit policy: 30% deposit to secure production slot; 70% balance due prior to shipment

Lead time guarantees:

7–14 days for standard specifications (e.g., 0.1–20mm PP/PS sheets)

21 days for custom configurations (flame-retardant, surface resistance tuning)

98% on-time delivery rate backed by integrated logistics partnerships

Technical Expertise & Customization

ISO 9001:2015-certified quality control across all production stages

Precision surface resistance control:

ESD-safe: 10³–10⁵ Ω (for sensitive electronics handling)

Anti-static: 10⁶–10⁹ Ω (for packaging, conveyor systems, and static-sensitive environments)

Material versatility:

| Material Type | Key Applications |

|—————|——————|

| PP Conductive | Automotive interiors, agricultural trays, construction barriers |

| PS Conductive | Electronics packaging, medical device components |

| HIPS Conductive | Logistics containers, dustproof enclosures |

| Flame-Retardant PP | High-safety zones (e.g., chemical storage, electrical enclosures) |

Dedicated engineering team: On-site support for material selection, design optimization, and compliance testing (e.g., IEC 61340, ANSI/ESD S20.20)

Core Manufacturing Capabilities

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-speed lines (0.1–200mm thickness range) |

| Quality Certification | ISO 9001:2015 |

Ready to optimize your 2026 supply chain?

👉 Request a custom sample and technical datasheet today:

📧 [email protected] | 📞 +86 577 8888 9999 | 🌐 www.everplast.com

All samples shipped within 48 hours of order confirmation.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.