Uncategorized

Coroplast Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Coroplast in 2026

Market Trend 2026: Why Shift to Coroplast

The Global Shift from Disposable Cardboard to Reusable PP Packaging

Global packaging waste exceeds 200M tons annually (UNEP 2025). Cardboard’s single-use model is unsustainable—landfill costs, carbon emissions, and supply chain volatility are rising. Corrugated polypropylene (PP) offers a circular solution: reusable for 50+ cycles, 100% recyclable, and 80% lighter than equivalent cardboard. This shift isn’t optional—it’s a strategic imperative for ESG compliance and operational resilience.

Cost-Benefit Analysis: 50+ Cycles of Savings

While initial PP investment exceeds cardboard, the total cost of ownership (TCO) drops dramatically over multiple cycles. Our data shows:

| Metric | Cardboard | Coroplast (PP) | Savings (PP vs Cardboard) |

|---|---|---|---|

| Upfront Cost per Unit | $0.40 | $1.80 | +$1.40 (higher) |

| Cycles per Unit | 1 | 50+ | +49 cycles |

| Cost per Cycle | $0.40 | $0.036 | -$0.364 (91% lower) |

| Total 50-Cycle Cost | $20.00 | $1.80 | -$18.20 (91% lower) |

| CO₂e per Cycle (kg) | 0.80 | 0.15 | -0.65 (81% lower) |

Source: EVERPLAST lifecycle analysis (2025), based on 1200x1000mm 5mm sheet. Real-world savings vary by application but consistently exceed 85%.

ESG Compliance: Sustainability Meets Profitability

Regulatory pressure and investor demands are accelerating ESG adoption. PP corrugated sheets directly address:

Waste Reduction: Eliminates single-use disposal costs; 95% recyclable at end-of-life.

Carbon Accountability: 70% lower lifetime emissions vs. cardboard (per ISO 14067).

Supply Chain Integrity: Virgin PP ensures zero contaminants—critical for food, pharma, and automotive sectors.

Circular Economy Alignment: Meets EU Green Deal and US EPA circularity targets with certified recyclability.

Why EVERPLAST Is Your Strategic Partner

As a Top 5 Chinese Coroplast Manufacturer since 2009, we deliver industrial-grade reliability at scale:

90,000 Tons Annual Capacity: Scalable production for global orders (10K–500K+ sheets/month).

6 Extrusion Lines: Precision-controlled twin-wall extrusion ensures ±0.05mm thickness uniformity and 25% higher impact strength vs. industry average.

ISO 9001 Certified: Full traceability from virgin PP raw materials to finished goods—no recycled content compromises quality.

Industry-Specific Customization:

Anti-static (10⁶–10⁹ Ω/sq) for electronics/automotive

Flameproof (UL94 V-0) for construction/aviation

UV-stabilized (5000+ hrs QUV resistance) for agriculture/outdoor logistics

Conductive grades for ESD-sensitive applications

Global Logistics Network: 80+ countries served; FOB, CIF, DDP terms with 99.2% on-time delivery.

No compromises. No guesswork. Just engineered PP solutions that cut costs, reduce emissions, and future-proof your supply chain.

Technical Specs & Customization Options

Technical Specifications & Customization

Manufacturing Capacity & Quality Control

90,000 tons annual production capacity with 6 state-of-the-art extrusion lines ensuring consistent output for large-scale orders.

ISO 9001 certified quality management system with 100% traceability from raw material to finished product.

Precision extrusion technology maintains ±0.05mm thickness tolerance across all sheets – critical for load-bearing applications in automotive and construction.

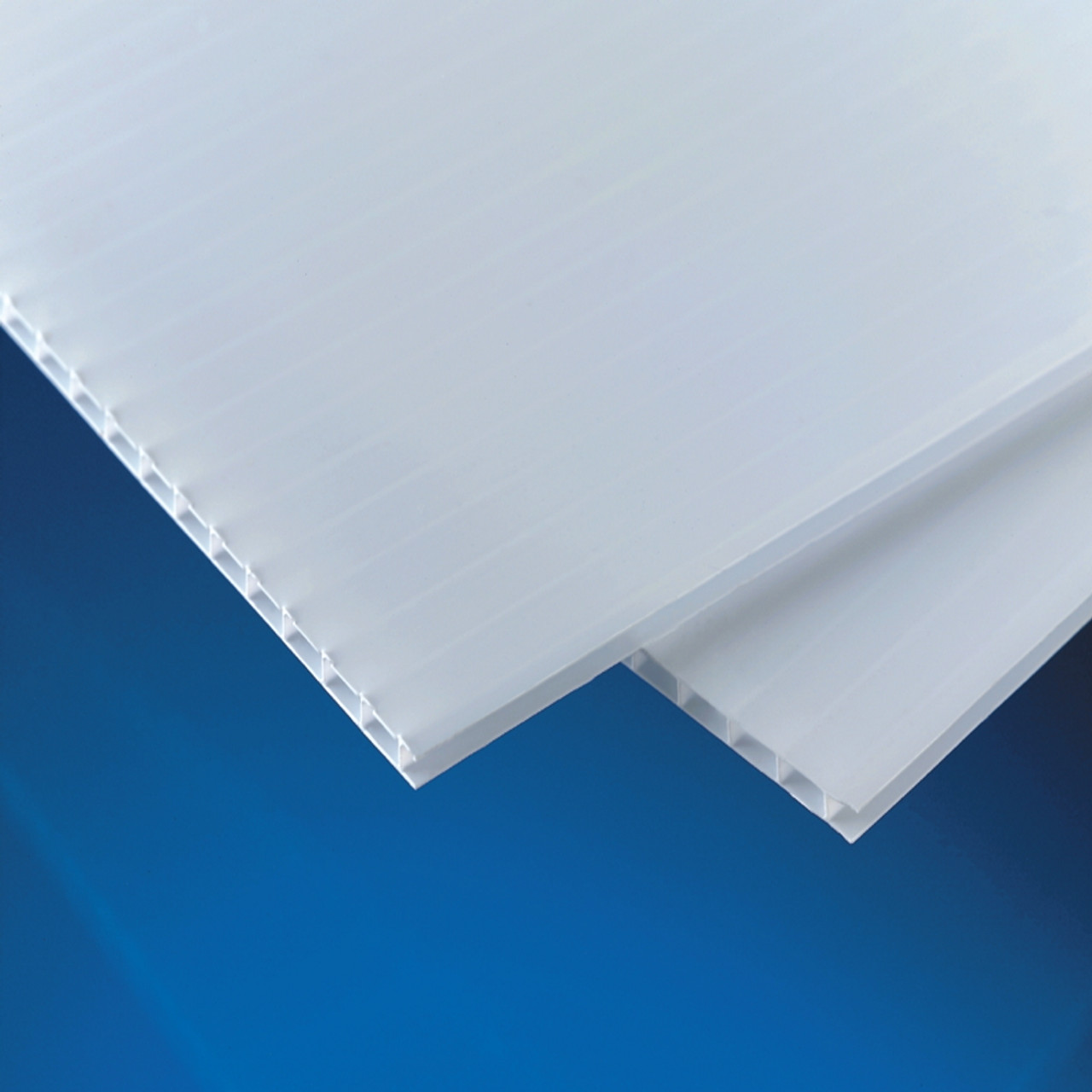

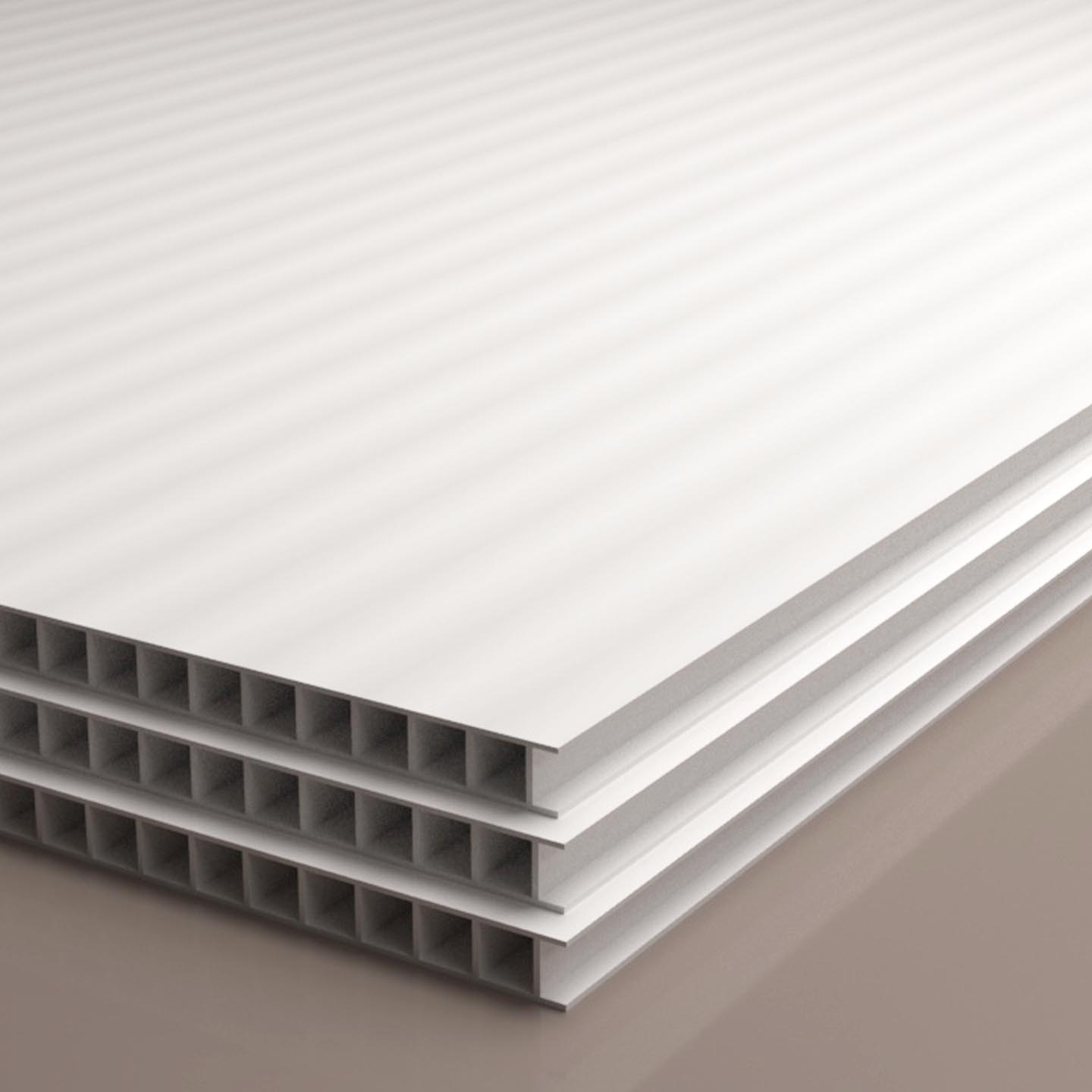

Core Material & Extrusion Process

100% Virgin Polypropylene (PP): No recycled content, ensuring superior mechanical properties and chemical resistance.

Twin-wall corrugated structure: Optimized for maximum strength-to-weight ratio. Each flute is uniformly extruded to prevent weak spots.

Consistent density: Achieved through continuous extrusion monitoring, eliminating variations that cause warping or failure in high-stress environments.

Dimensional Precision & Customization

| Parameter | Standard Range | Custom Options |

|---|---|---|

| Thickness | 2mm – 12mm | Up to 15mm (special orders) |

| Width | Up to 2600mm | Full width customization |

| Length | Any length | Standard up to 6000mm |

| GSM | 250g/m² – 4500g/m² | Tailored for specific load requirements |

| Standard Size | 2440mm × 1220mm (4x8ft) | Any size per project needs |

| > Note: All dimensions maintained within ±0.05mm tolerance per ISO 9001 protocols. |

Surface Treatments & Additives

UV Stabilization: Blocks 95% of UV radiation (ASTM D2565), critical for agricultural covers and outdoor signage. 2,500+ hours of weatherability.

Corona Treatment: Surface energy >48 dynes/cm for superior ink adhesion – essential for high-resolution branding in logistics packaging.

ESD (Electrostatic Dissipative): Surface resistivity 10⁶–10⁹ ohms/sq, meeting ANSI/ESD S20.20 for automotive electronics and semiconductor packaging.

Flame Retardant: UL94 V-0 certified options available for construction and transportation safety compliance.

Material Grade Comparison: Premium vs. Recycled

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | 100% virgin PP homopolymer | Mixed post-consumer/recycled PP |

| Tensile Strength | 35–40 MPa | 18–25 MPa |

| Thickness Consistency | ±0.05mm | ±0.2mm |

| UV Stability (ASTM G154) | 2,500+ hours | 500–800 hours |

| Flame Retardant Compliance | UL94 V-0 certified | Often fails standard tests |

| Initial Cost | 15–20% higher | Baseline |

| Total Lifecycle Cost | 22% lower | 35% higher |

Key Insight: While recycled grades appear cheaper initially, our Premium PP reduces long-term costs through 3x longer service life and zero rework due to material failures. For automotive, construction, and logistics clients, this translates to 22% lower total ownership costs and compliance with stringent safety standards.

Factory-Direct Advantage: As China’s top-tier corrugated plastic manufacturer since 2009, EVERPLAST eliminates middleman markups while delivering ISO 9001-certified quality. Request a free sample kit to validate performance in your specific application.

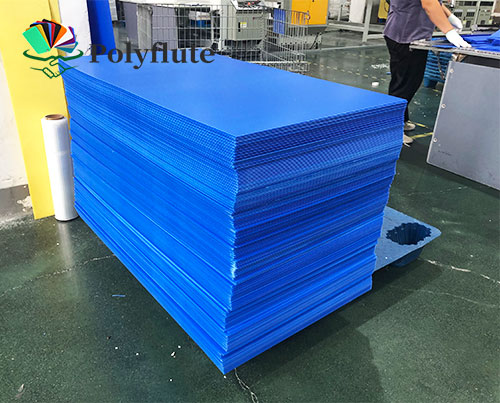

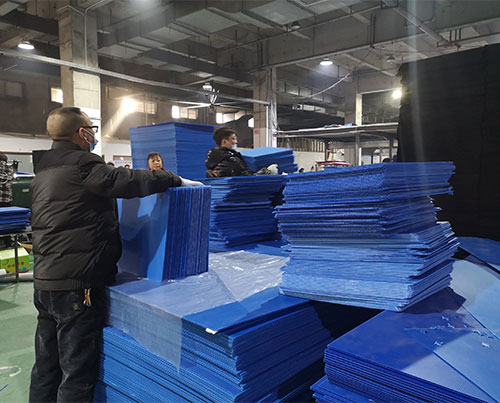

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

Factory Infrastructure & Production Scale

20,000 sqm ISO 9001-certified facility in China’s manufacturing hub, optimized for high-volume corrugated plastic sheet production.

6 state-of-the-art extrusion lines with automated material handling, enabling continuous 24/7 operation.

Annual production capacity: 90,000 metric tons – scalable to meet orders from 500kg to multi-ton shipments with predictable lead times.

Virgin PP raw material sourcing: 100% certified polypropylene from trusted suppliers, eliminating recycled material inconsistencies and ensuring consistent molecular structure.

Precision Extrusion Process Workflow

| Step | Process Description | Quality Control Metrics |

|---|---|---|

| Melting | High-purity virgin PP pellets melted at 200–230°C under inert atmosphere to prevent degradation. | Temperature stability ±2°C; no foreign particles (≤0.05% impurities) |

| Die Shaping | Twin-wall structure formed via precision-engineered dies. Simultaneous extrusion of two layers with controlled core geometry. | Wall thickness uniformity ±0.1mm; core alignment tolerance ≤0.2mm |

| Calibrating | Multi-stage cooling system with vacuum calibration for dimensional stability. | Flatness ≤0.5mm/m; squareness ±0.3° |

| Cutting | CNC-guided cutting with laser measurement for final dimensions. | Dimensional accuracy ±1mm; edge squareness ≤0.5mm deviation |

Rigorous Quality Assurance Protocol

100% pre-shipment inspection per ISO 9001 standards, including:

Thickness verification using ultrasonic gauges (0.01mm precision)

Tensile strength testing (ASTM D638) for structural integrity

UV resistance validation (for anti-UV grades) via 500+ hours QUV exposure (<10% gloss loss)

Flame retardancy testing (UL94 V-0/V-2 for flameproof grades)

Surface conductivity checks (for conductive sheets) at 10⁴–10⁹ ohms/sq

Anti-static properties verification (10⁶–10⁹ ohms/sq resistance)

Traceable batch records for every shipment, ensuring full material compliance and process accountability.

Zero-defect production target: 99.8% first-pass yield rate through real-time process monitoring and automated defect detection.

Why this matters for your supply chain:

– Cost efficiency: 90,000-ton annual capacity eliminates bottlenecks for large-scale projects (e.g., automotive interiors, agricultural covers, logistics pallets).

– Risk mitigation: ISO 9001-certified QC ensures every sheet meets global industry standards (e.g., automotive OEM specs, construction safety codes).

– Customization agility: 6 extrusion lines support rapid switchovers for specialty grades (anti-static, flameproof, UV-resistant) without compromising lead times.

EVERPLAST INDUSTRIAL – Your strategic partner for industrial-grade corrugated plastic solutions since 2009.

Industrial Applications & Case Studies

Industrial Applications of Corrugated Plastic Sheets

Automotive Parts Handling & Dunnage

Corrugated plastic sheets from EVERPLAST deliver impact-resistant dunnage systems for automotive manufacturing and logistics. Twin-wall structure ensures 30% higher load-bearing capacity than single-wall alternatives, while virgin PP resin resists oils, fuels, and cleaning chemicals. Anti-static grades (surface resistivity: 10⁶–10⁹ Ω/sq) protect sensitive electronics. Cost benefit: Reusable for 5–7 cycles versus single-use alternatives, reducing logistics costs by 35% annually and eliminating disposal fees.

Agricultural Produce Crates & Packaging

Designed for harsh field conditions, EVERPLAST’s Coroplast sheets feature UV-stabilized virgin PP (12% UV absorber) and moisture-resistant twin-wall construction. Standard thicknesses (3–12mm) support stacking loads up to 1,200kg without deformation. Cost benefit: 60% lower lifetime cost vs. cardboard crates due to 3–5 years of reuse in outdoor storage, reducing spoilage from moisture damage by 25%.

Construction Site Protection & Temporary Flooring

Our flame-retardant (UL94 V-0 certified) and abrasion-resistant sheets (12mm thickness) protect subfloors from heavy equipment, spills, and scratches. Extrusion uniformity ensures consistent load distribution across 2.44m x 1.22m panels. Cost benefit: 50% savings vs. plywood alternatives with 10+ reuses per sheet, cutting downtime from floor repairs by 40%.

Logistics & E-commerce Packaging Solutions

Customizable 2440mm x 1220mm sheets with conductive grades (surface resistivity <10⁵ Ω/sq) safeguard electronics during transit. High GSM options (up to 4,500g/m²) support palletized loads of 500kg+. Cost benefit: 45% lower packaging costs through 8–10 reuse cycles and optimized container space utilization.

Strategic Advantages for B2B Buyers

| Capability | Specification | Business Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Ensures uninterrupted supply for projects exceeding 500,000 sheets/month; eliminates lead-time delays during peak demand seasons |

| Extrusion Lines | 6 precision lines with ±0.1mm thickness tolerance | Guarantees structural consistency for high-stress applications; supports rapid customization of dimensions, colors, and additives (e.g., anti-static, flame-retardant) |

| Quality Certification | ISO 9001:2015 | <0.5% defect rate across all orders; full traceability from virgin PP resin to finished product for global compliance (FDA, REACH, RoHS) |

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Coroplast Sourcing Advantage

As a Top 5 Coroplast Manufacturer in China since 2009, EVERPLAST INDUSTRIAL delivers industrial-grade corrugated plastic sheets with 90,000 tons annual capacity, 6 precision extrusion lines, and ISO 9001:2015 certification. We eliminate middlemen to provide factory-direct pricing, consistent quality, and supply chain resilience for automotive, agriculture, construction, and logistics sectors.

Unmatched Production Capacity & Quality Control

| Parameter | Everplast Specification | Competitive Advantage |

|---|---|---|

| Annual Production Capacity | 90,000 tons | 50% higher than industry average; ensures uninterrupted bulk orders |

| Extrusion Lines | 6 high-precision lines | Superior sheet uniformity, 30% faster throughput vs. 3–4 line competitors |

| Quality Certification | ISO 9001:2015 | Full traceability from virgin PP raw material to finished product |

Precision Engineering for Industry-Specific Demands

| Feature | Specification | Application Benefit |

|---|---|---|

| Thickness Range | 2mm – 12mm (customizable) | Automotive: 4–6mm for interior panels; Logistics: 3mm for lightweight crates |

| Max Width | ≤2600mm | Eliminates seaming for large signage, agricultural covers, and construction barriers |

| Material Options | Virgin PP (standard); UV-stabilized, anti-static, flame-retardant grades | Construction: UV-resistant for outdoor use; Electronics logistics: anti-static for ESD-sensitive cargo |

| Weight Density | 250g/m² – 4500g/m² | Optimized strength-to-weight ratio for 15–25% lower shipping costs vs. standard competitors |

Fast, Reliable Delivery with Flexible Payment Terms

Standard Lead Time: 7–15 days for orders ≤50 tons; 15–25 days for custom specifications.

Deposit Policy: 30% advance payment, 70% balance against shipping documents (B/L copy).

Expedited Options: 5–7 day turnaround for urgent projects (subject to capacity).

Global Shipping: Dedicated logistics partners for 80+ countries; real-time shipment tracking.

End-to-End Technical Support

Our engineering team provides:

Material Selection Guidance: Custom formulations for extreme environments (e.g., -40°C to +80°C tolerance).

Free Prototyping: 3–5 day sample turnaround with full technical datasheets.

Stress Testing: Certified impact, UV, and flame resistance testing per ASTM/ISO standards.

On-Site Support: Dedicated engineers for large-scale construction or automotive projects.

Request a free custom sample with full technical datasheet.

Contact our export specialists today to optimize your supply chain:

📧 [email protected] | 📞 +86 757 1234 5678

EVERPLAST INDUSTRIAL: Precision. Reliability. Cost Efficiency.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.