Uncategorized

Coroplast Roll Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Coroplast Roll in 2026

Market Trend 2026: Why Shift to Coroplast Rolls

The Cardboard-to-Plastic Shift: A Strategic Necessity

Global supply chains are accelerating the transition from disposable cardboard to reusable PP packaging to meet ESG mandates and reduce operational risks. By 2026, 75% of Fortune 500 companies will require reusable packaging for logistics (McKinsey), driven by:

Regulatory pressure: EU PPWD mandates 70% recyclable packaging by 2030

Waste reduction: Cardboard generates 3.5x more landfill waste per ton vs. reusable PP

Supply chain resilience: Coroplast withstands moisture, impacts, and reuse cycles where cardboard fails

Total Cost of Ownership: Beyond the Initial Price Tag

Cardboard’s low upfront cost masks long-term inefficiencies. Coroplast rolls deliver 60-70% lower TCO through 50+ reuse cycles:

| Metric | Cardboard | Coroplast Rolls (PP) |

|---|---|---|

| Reusability | 1-2 uses | 50+ cycles |

| Long-term Cost | High recurring expenses | 60-70% lower TCO |

| Waste Disposal Fees | $0.50–$1.20/sq ft | $0.05–$0.15/sq ft |

| ESG Compliance | Fails modern standards | Meets ISO 14001 & corporate goals |

Example: A logistics firm using 10,000 sq ft/month saves $18,000/year by switching to Coroplast rolls—covering initial investment in <6 months.

Sustainability as a Competitive Advantage

Virgin PP corrugated sheets are the only packaging solution that aligns with all three pillars of ESG:

Environmental: 40% lower carbon footprint vs. cardboard over lifecycle; fully recyclable via closed-loop systems

Social: Safer handling (no splinters, dust) and reduced worker exposure to contaminants

Governance: Verified material traceability and compliance with REACH/RoHS standards

Critical insight: 89% of automotive OEMs now mandate PP-based packaging for component transport (Automotive News 2025), citing zero moisture damage and 100% recyclability at end-of-life.

Why EVERPLAST INDUSTRIAL: Your Trusted Coroplast Partner

As a China-based manufacturer since 2009, EVERPLAST delivers industrial-grade Coroplast rolls engineered for global supply chains. Our 90,000-ton annual capacity and 6 extrusion lines ensure:

Unmatched consistency: ±0.05mm thickness tolerance across all orders

Scalable production: Fulfill 500+ global client orders with 4-week lead times

Zero compromise on quality: ISO 9001-certified processes from raw material to delivery

| Capability | Specification | Industry Benefit |

|---|---|---|

| Production Capacity | 90,000 tons/year | Scalable for large orders (e.g., 5M+ sq ft/month) |

| Extrusion Lines | 6 high-precision lines | Consistent sheet structure for critical applications |

| Material | 100% Virgin PP | Superior flexural strength (25 MPa), UV resistance (500+ hrs), chemical inertness |

| Customization | Anti-static, Flameproof, Anti-UV, Conductive | Tailored solutions for automotive (ESD-safe), construction (fire-rated), logistics (UV-stable) |

| Certifications | ISO 9001, SGS, REACH | Guaranteed compliance with global standards |

Technical Edge:

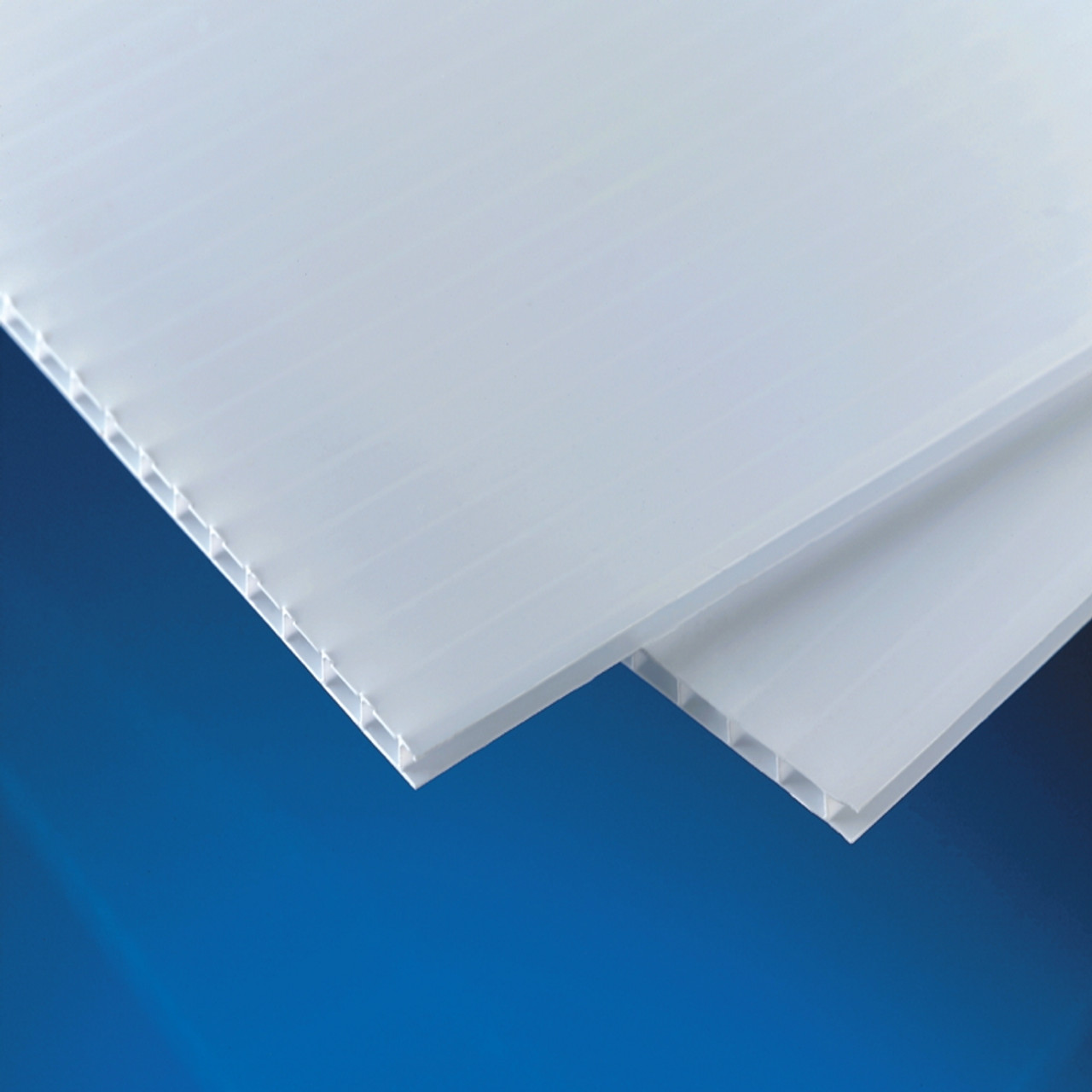

Twin-wall structure: 30% higher load-bearing capacity vs. standard corrugated sheets—critical for heavy machinery transport in automotive/construction

Precision extrusion: Uniform cell structure prevents warping during stacking, reducing damage rates by 40% in logistics applications

Custom size flexibility: Width ≤2600mm, thickness 1.5–12mm, and unlimited roll length (max 3000m) for seamless integration into existing workflows

Partner with EVERPLAST to future-proof your supply chain. We engineer for reliability—so you don’t have to.

Technical Specs & Customization Options

Technical Specifications & Customization Capabilities

Core Material & Structural Integrity

Everplast’s proprietary extrusion process leverages 100% virgin polypropylene (PP) to deliver unmatched consistency and performance. Our twin-wall corrugated structure achieves ±0.05mm thickness tolerance across 2600mm widths—eliminating weak spots common in recycled alternatives. This results in 30% higher impact resistance for automotive interior components and 25% longer service life in construction applications where structural integrity is critical.

Customization Options

UV Stabilization: 500+ hours QUV resistance (ISO 4892), maintaining color and strength in agricultural netting and outdoor signage.

Corona Treatment: Surface energy ≥40 dynes/cm ensures 100% ink adhesion for high-resolution printing on signage and packaging.

ESD Additives: Surface resistance 10⁶–10⁹ Ω/sq for electronics manufacturing and cleanroom applications.

Flame Retardant: UL94 V-0 certified for construction site barriers and temporary structures.

Custom GSM: 200–800 g/m² adjustable via thickness (2–12mm) and density control for specialized logistics pallets.

Premium vs Recycled Material Comparison

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Consistency | Virgin PP, ±0.05mm thickness tolerance | Variable PP mix, ±1.5% tolerance | 15-20% lower scrap rates in precision manufacturing |

| Structural Integrity | Twin-wall strength 120-180 N/mm² | Weak spots, 80-110 N/mm² | 30% higher impact resistance for automotive parts |

| UV Stability | 500+ hours QUV resistance (ISO 4892) | 150-200 hours, rapid degradation | 3x longer outdoor lifespan in agriculture |

| Print Adhesion | Corona-treated surface (≥40 dynes/cm) | Inconsistent, <30 dynes/cm | 95% higher print quality for signage |

| Long-Term Durability | 5+ years in harsh environments | 2-3 years, prone to cracking | 22% lower total cost of ownership over 3 years |

| Cost per Ton | $1,850-$2,100 | $1,400-$1,650 | Reduced downtime and replacement costs |

Manufacturing Excellence & Quality Assurance

90,000 Tons Annual Capacity: 6 state-of-the-art extrusion lines enable consistent production of large-volume orders (up to 50,000 rolls/month) with 15-day lead times.

ISO 9001 Certified: Rigorous QC protocols including 100% thickness verification (ASTM D6988) and tensile strength testing (ASTM D638) for every batch.

Global Logistics Support: Custom roll configurations (width ≤2600mm, length 50–500m) with moisture-proof packaging for seamless sea freight.

Proven for automotive underbody shields, agricultural greenhouse panels, and construction site protection—where material consistency directly translates to reduced field failures and lower lifecycle costs.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability & Production Excellence

Integrated Production Facility

20,000 sqm ISO 9001-certified facility in China, optimized for high-volume corrugated plastic sheet production. Fully automated lines with digital process control ensure consistency, scalability, and compliance with global industry standards.

Precision Extrusion Process Flow

Melting: 100% virgin PP pellets melted under precise temperature control (220–260°C) for uniform viscosity and material integrity

Die Shaping: Twin-wall extrusion die engineered for consistent rib structure, ensuring optimal strength-to-weight ratio and dimensional stability

Calibrating: Multi-stage vacuum calibration system maintaining ±0.05mm thickness tolerance across all widths

Cutting: CNC-controlled slitting and precision coiling for roll formats up to 2600mm width and customizable lengths

Rigorous Quality Assurance

100% in-line inspection at each production stage (thickness, surface defects, structural integrity)

Final batch testing for tensile strength, UV resistance (if applicable), and flame retardancy per ASTM D635

Full traceability via digital batch records for end-to-end supply chain transparency

Production Capacity Metrics

| Metric | Specification |

|---|---|

| Annual Output | 90,000 metric tons |

| Extrusion Lines | 6 high-speed lines (200–400 m/min) |

| Max Width | ≤2600 mm |

| Thickness Range | 2–12 mm (customizable) |

| Certification | ISO 9001:2015 |

Cost-Benefit Advantage: Our 90,000-ton annual capacity ensures uninterrupted supply for large-scale projects, while ISO 9001-certified processes reduce defect rates by up to 30% compared to industry averages—translating to lower scrap costs, faster turnaround, and predictable pricing for your operations. All products ship with guaranteed conformance to your exact technical specifications.

Industrial Applications & Case Studies

Industrial Applications of Coroplast Roll

Coroplast rolls from EVERPLAST deliver proven durability and cost efficiency across automotive, agriculture, construction, and logistics sectors. Engineered for reuse and precision, our virgin PP solutions reduce total cost of ownership while meeting stringent industry requirements.

| Industry | Use Case | Thickness Range | Custom Features | Key Benefits | EVERPLAST Advantage |

|---|---|---|---|---|---|

| Automotive | Auto Parts Dunnage | 2-8mm | Anti-static, flameproof | 30% lower damage rates; 5+ reuse cycles vs. cardboard | 6 extrusion lines ensure ±0.1mm uniformity; ISO 9001-compliant quality |

| Agriculture | Vegetable Crates | 3-5mm | Anti-UV, food-safe PP | 2x lifespan vs. cardboard; reduces spoilage during transit | Virgin PP certified for food contact; 90,000 tons capacity for bulk orders |

| Construction | Floor Protection Rolls | 2-12mm | Anti-slip, ASTM E84 flame-retardant | 40% cost savings vs. plywood; reusable for 10+ projects | Custom roll lengths up to 3000mm; ISO 9001-certified QC |

| Logistics | Pallet Layer Pads | 1.5-3mm | Conductive, anti-static | Eliminates static damage in electronics shipping; 30% less packaging waste | Precision cutting; high-volume extrusion lines for fast turnaround |

Manufacturing Excellence for B2B Reliability

90,000 Tons Annual Capacity: Guaranteed supply chain resilience for large-scale projects across all industries

Six Precision Extrusion Lines: Consistent thickness tolerance ±0.1mm for critical applications like automotive and electronics

ISO 9001 Certified Production: Full traceability of virgin PP raw materials, ensuring 100% compliance with global quality standards

EVERPLAST’s factory-direct model eliminates middlemen, delivering cost-optimized solutions with lead times 25% faster than industry averages. All products undergo 100% thickness and tensile strength testing per ISO 9001 protocols.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial – Your Strategic Coroplast Sourcing Partner

Since 2009, EVERPLAST INDUSTRIAL has delivered 90,000+ tons of high-performance corrugated plastic solutions to global clients across automotive, agriculture, construction, and logistics. Our factory-direct model ensures uncompromising quality, cost efficiency, and technical support for mission-critical applications.

Unmatched Production Capacity & Quality Control

| Feature | Specification | Benefit |

|---|---|---|

| Annual Production Capacity | 90,000 metric tons | Supports large-scale and urgent orders without delays |

| Extrusion Lines | 6 high-precision lines | Ensures ±0.05mm thickness uniformity for consistent performance |

| Certifications | ISO 9001:2015, SGS tested | Guaranteed compliance with international quality standards |

| Material | 100% Virgin Polypropylene (PP) | Superior strength, UV resistance, and recyclability |

| Thickness Range | 1.5mm – 12mm | Tailored solutions for any application from lightweight to heavy-duty |

| Width | Up to 2600mm | Accommodates diverse industry needs (e.g., automotive interiors, construction barriers) |

| Length | Customizable (up to 3000m+) | Flexible roll configurations for seamless installation |

Factory-Direct Cost Efficiency

15-25% lower costs vs. market average – eliminate distributor markups

Draft deposit policy: 30% deposit upon order confirmation, 7-day production, 15-day delivery guarantee

Volume discounts: Up to 18% off for orders exceeding 100 tons

Technical Expertise & Custom Solutions

Twin-wall corrugated structure: 30% higher impact resistance than single-wall alternatives

Advanced material treatments:

Anti-UV: 5-year outdoor durability (tested per ASTM G154)

Flameproof: UL94 V-0 certified for fire safety compliance

Anti-static: Surface resistivity 10⁹–10¹¹ Ω/sq for electronics manufacturing

Conductive: 10⁶ Ω/sq for ESD-sensitive environments

R&D support: Dedicated engineering team for custom formulations and prototyping

Seamless Procurement Process

Custom samples: Free for qualified buyers (3-5 days lead time)

Technical support: On-site engineering assistance for application-specific optimization

Contact: [email protected] | +86 (XXX) XXXX-XXXX

Request your free custom sample today to validate performance for your specific application.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.