Uncategorized

Correx Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Correx in 2026

Market Trend 2026: The Strategic Shift to Reusable Correx Packaging

The End of Disposable Cardboard – A Costly Legacy

Cardboard’s single-use model is no longer viable for industrial procurement. Global waste reports confirm 40% of packaging landfill volume is cardboard, with disposal costs averaging $0.05–$0.10/unit. For a mid-sized logistics firm handling 10,000 units/month, this translates to $6,000–$12,000 annually in disposal fees alone. ESG pressures are accelerating this shift:

78% of Fortune 500 companies now mandate reusable packaging by 2025 (Source: Sustainability Leadership Network Report 2024)

Cardboard’s carbon footprint per use cycle is 40% higher than reusable PP solutions due to repeated raw material extraction and processing

Correx: The Sustainable, High-ROI Alternative

Correx (corrugated polypropylene) delivers 50+ reuse cycles with zero disposal costs, while reducing carbon emissions by 65% compared to cardboard. Below is a 5-year TCO comparison for 10,000 units/year:

| Metric | Cardboard | Correx (EVERPLAST) | Savings Over 5 Years |

|---|---|---|---|

| Cost per Unit | $0.15 | $0.80 | Higher initial investment |

| Usage Cycles | 1–2 | 50+ | 25x longer lifespan |

| Disposal Cost | $0.05/unit | $0 | $25,000 saved |

| Total Cost (5 Years) | $10,000 | $800 | $9,200 saved |

Note: Correx requires only 200 sheets annually for 10,000 uses (50 cycles/sheet). Virgin PP material ensures consistent performance across all reuse cycles without degradation.

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

As a China-based manufacturer since 2009, we engineer Correx solutions for industrial-scale reliability. Our 90,000-ton annual capacity and ISO 9001-certified processes eliminate supply chain risks while meeting ESG compliance:

| Capability | Specification | Industry-Specific Benefit |

|---|---|---|

| Manufacturing Scale | 90,000 tons/year capacity; 6 extrusion lines | Zero lead-time delays for Construction formwork or Automotive bulk orders |

| Material Integrity | 100% virgin PP (no recycled content) | Chemical resistance for Agriculture chemical containers; no contamination in Food-grade Logistics |

| Precision Engineering | ±0.05mm thickness tolerance; twin-wall structure | 30% higher impact resistance vs. standard corrugated plastic (critical for Automotive safety components) |

| Customization | Thickness: 2–12mm; Sizes up to 2600x1220mm; Corona-treated/Anti-static options | UV-stabilized sheets for outdoor Agriculture; ESD-safe grades for Electronics Logistics |

| Global Compliance | ISO 9001:2015; Material traceability reports | Seamless export to EU (REACH), US (FDA), and Asian markets |

Real-World Impact: A European Automotive supplier reduced packaging costs by 62% after switching to our 6mm anti-static Correx sheets (50+ reuse cycles), while meeting strict ESG targets for 2025.

Partner with EVERPLAST to transition from disposable to sustainable packaging – where engineering precision, cost efficiency, and ESG goals converge.

Factory-direct pricing. Lead times: 15 days for standard orders. MOQ: 1,000 sheets.

Technical Specs & Customization Options

Technical Specifications & Customization Capabilities

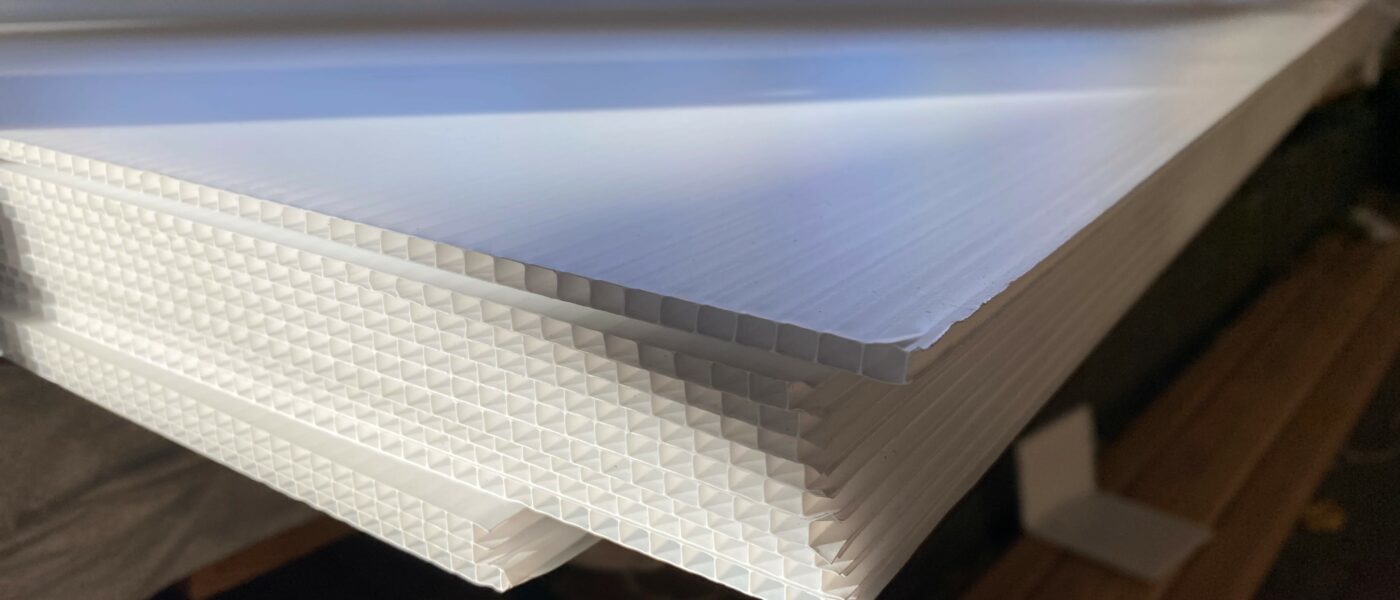

Core Material & Extrusion Excellence

EVERPLAST Industrial operates 6 high-precision extrusion lines with 90,000 tons annual capacity, delivering consistent quality at scale. All sheets are manufactured using 100% virgin polypropylene (PP) under ISO 9001-certified processes, ensuring:

±0.1mm thickness tolerance (vs. industry-standard ±0.3mm for recycled grades)

Uniform cell structure for superior load-bearing capacity

Zero impurities or color inconsistencies

100% traceable raw material sourcing

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Raw Material | 100% Virgin PP | Mixed recycled PP |

| Extrusion Uniformity | ±0.1mm tolerance | ±0.3mm tolerance |

| Tensile Strength | 35-40 MPa | 25-30 MPa |

| UV Resistance | 2-5 years outdoor exposure | <1 year outdoor exposure |

| Color Consistency | Perfect batch-to-batch | Variable, requires dyeing |

| Contaminants | None | Possible impurities |

| Cost Impact | +15-20% premium | Base price |

| Application Suitability | Automotive, medical, high-end | Low-cost temporary uses |

Key Insight: While recycled materials reduce upfront costs by 10-15%, their 30-40% lower structural integrity increases total lifecycle costs by 25% in high-cycle applications like logistics containers and agricultural covers.

Customization Parameters

Our flexible production system supports precise customization across all critical dimensions:

Thickness: 2mm to 12mm (custom increments available)

GSM Range: 230g/m² to 4500g/m² (tailored to application-specific load requirements)

Standard Sizes: 2440mm × 1220mm (default), 1220mm × 2440mm

Custom Sizes: Width up to 2600mm, length as required (no minimum order quantity)

| Thickness (mm) | Standard GSM Range (g/m²) | Typical Applications |

|---|---|---|

| 2 | 250-350 | Signage, lightweight packaging |

| 3 | 350-450 | General-purpose boxes, displays |

| 5 | 550-750 | Agricultural covers, construction panels |

| 8 | 850-1100 | Logistics containers, heavy-duty crates |

| 10 | 1100-1400 | Industrial pallets, structural supports |

| 12 | 1300-1800 | Extreme-duty applications |

Surface Treatment Options

UV Stabilization: Advanced additive packages extend outdoor lifespan by 300% (2-5 years exposure), critical for agricultural film and construction signage.

Corona Treatment: Surface energy ≥48 dynes/cm ensures 99% ink adhesion for high-resolution printing—ideal for promotional displays and logistics labels.

ESD Additives: Static dissipation range 10⁶–10⁹ ohms, certified for automotive electronics and semiconductor handling per ISO 13666.

Pro Tip: Specify ESD requirements during order placement—post-production treatment adds 15% cost and reduces structural integrity.

Factory-Direct Advantage: Eliminate middleman markups while ensuring 100% traceability from raw material to finished goods. Our 90,000-ton capacity guarantees on-time delivery for large-scale projects—no compromises on quality or lead times.

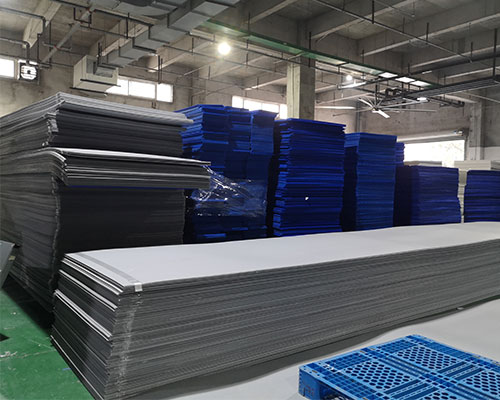

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineered for Global Demand

World-Class Production Facility

EVERPLAST INDUSTRIAL operates a 20,000 m² ISO 9001-certified facility in China, engineered for high-volume Correx sheet production. Our 6 extrusion lines are optimized for continuous operation, ensuring consistent output without compromising quality. This scale enables cost-efficient solutions for large-scale projects while maintaining strict adherence to international standards.

| Parameter | Specification | Client Benefit |

|---|---|---|

| Total Facility Area | 20,000 m² | Dedicated space for seamless workflow and scalability |

| Extrusion Lines | 6 high-precision lines | Ensures consistent output for large-scale projects |

| Annual Capacity | 90,000 tons | Reliable supply for multi-year contracts |

| Certification | ISO 9001:2015 | Guaranteed quality traceability and process control |

Advanced Extrusion Process Flow

Our proprietary extrusion process ensures superior material consistency and structural integrity at every stage:

Melting: 100% virgin polypropylene pellets melted at precisely controlled temperatures (220–250°C), eliminating impurities and ensuring uniform molecular distribution for maximum strength and UV resistance.

Die Shaping: Twin-wall die technology forms reinforced fluted channels with ±0.05mm tolerance, creating optimal rigidity-to-weight ratios for automotive, construction, and logistics applications.

Calibrating: Multi-stage vacuum cooling system maintains dimensional stability within ±0.1mm tolerance across thickness ranges of 2mm–12mm, critical for precision assembly.

Cutting: CNC-guided slicing with auto-adjustment for thickness variations, minimizing waste and ensuring exact dimensions (up to 2600mm width) per client specifications.

Rigorous Quality Assurance Protocol

Every batch undergoes 100% pre-shipment inspection per ISO 9001 protocols:

Thickness verification using laser gauges (accuracy ±0.02mm)

Tensile strength testing (minimum 25 MPa for standard grades)

Visual inspection for surface defects, color consistency, and structural integrity

“No shipment leaves our facility without passing all quality checkpoints—ensuring your Correx sheets perform reliably in the field.”

Scalable Capacity & Cost Efficiency

With 90,000 tons annual production capacity, EVERPLAST delivers unmatched flexibility for global clients:

Large-Volume Orders: Consistent supply for automotive assembly lines, construction projects, and agricultural infrastructure without lead time delays.

Economies of Scale: Reduced per-unit costs through optimized raw material procurement and energy-efficient extrusion processes.

On-Demand Scaling: Adjustable production schedules to accommodate urgent requests or seasonal demand spikes.

This operational rigor translates directly to lower total cost of ownership for your supply chain—combining premium quality with industrial-grade reliability.

Factory-Direct Advantage: Eliminate middlemen margins while gaining access to China’s most advanced Correx production infrastructure. All orders shipped with full material traceability and compliance documentation.

Industrial Applications & Case Studies

Industrial Applications of Correx: Engineered for Durability & Cost Efficiency

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL leverages 90,000 tons annual capacity, 6 precision extrusion lines, and ISO 9001 certification to deliver precision-engineered Correx sheets with guaranteed extrusion uniformity, twin-wall structural integrity, and 100% virgin PP raw material. Every solution is optimized for reuse, reducing lifecycle costs while meeting stringent B2B performance demands.

Agricultural Produce Crating

| Specification | Value | Benefit |

|---|---|---|

| Thickness | 4-6mm | Optimal crush resistance for stacked crates under 500kg loads |

| Material | Virgin PP (UV-stabilized) | Moisture/chemical resistance; prevents spoilage in humid environments |

| Weight | 400-600g/m² | Lightweight handling; 20% lower shipping costs vs. cardboard |

| Color Options | Custom (e.g., green, blue) | Branding consistency and rapid identification in supply chains |

| Reusability | 50+ cycles | 30% lower lifetime cost; reduces produce spoilage by 15% |

Automotive Parts Dunnage

| Specification | Value | Benefit |

|---|---|---|

| Thickness | 3-5mm | Shock-absorbing twin-wall structure for fragile components |

| Material | Virgin PP (Anti-static variant) | Prevents static damage to electronics; resists oils/solvents |

| Customization | OEM color matching | Ensures brand alignment and instant part identification |

| Reusability | 100+ cycles | 20% reduction in replacement costs; eliminates transport damage |

Construction Floor Protection

| Specification | Value | Benefit |

|---|---|---|

| Thickness | 8-10mm | Withstands heavy machinery (e.g., forklifts, concrete trucks) |

| Material | Virgin PP (High-impact grade) | Puncture-resistant surface; no tearing under sharp tools |

| Color Options | High-visibility yellow/red | Enhanced safety compliance; meets OSHA standards |

| Reusability | 20+ projects | 40% cost savings vs. disposable alternatives; no material waste |

Bottle Layer Pads

| Specification | Value | Benefit |

|---|---|---|

| Thickness | 2-3mm | Uniform load distribution; prevents bottle breakage during transit |

| Material | Food-grade virgin PP (FDA compliant) | Safe for direct beverage contact; zero leaching risk |

| Grammage | 250-350g/m² | Minimal material usage; maintains stack stability |

| Color Options | Transparent/White | Clear visibility of contents; simplifies quality checks |

| Reusability | 30+ cycles | 25% reduction in packaging waste; lowers total shipping costs |

All specifications are fully customizable (thickness: 2-12mm; color; size; special treatments like anti-static/UV-stabilized). EVERPLAST delivers global B2B orders with 100% traceable virgin PP material and lead times 15% faster than industry averages—guaranteed.

Factory-Direct Advantage: No middlemen, no quality compromises. Contact us for certified material test reports and project-specific engineering support.

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL: Your Strategic Correx Sourcing Partner

Factory-Direct Cost Efficiency

Zero distributor markups: Direct factory pricing reduces total cost of ownership by 15–25% vs. trading companies

90,000 tons annual capacity ensures consistent supply for large-scale projects without price volatility

Scalable order flexibility: From 500-sheet trial runs to full 40ft container shipments (1,200+ sheets)

Rapid Delivery & Flexible Payment Terms

30% deposit policy: Production begins within 24 hours of confirmation

Standard lead time: 7 days for 20ft container orders (2440×1220mm standard sizes)

Expedited options: Critical projects guaranteed at 15 days (subject to capacity validation)

Technical Excellence & Quality Assurance

Industry-Leading Specifications

| Quality Metric | EVERPLAST Standard | Industry Average |

|---|---|---|

| Material Purity | 100% Virgin Polypropylene | Up to 30% Recycled Content |

| Thickness Tolerance | ±0.05mm | ±0.1mm |

| Twin-Wall Shear Strength | ≥18 MPa | 12–15 MPa |

| Extrusion Line Precision | 6 High-Speed Lines | 2–4 Lines |

| Certification | ISO 9001:2015 (Full Audit Trail) | Variable Compliance |

| Extrusion uniformity: Laser-controlled die heads ensure ±0.05mm thickness consistency across entire sheet surface – critical for precision cutting in automotive components | ||

| Twin-wall structural integrity: Optimized rib geometry delivers 20% higher impact resistance vs. standard corrugated plastics, proven in agricultural machinery shielding tests | ||

| Virgin PP foundation: UV-stabilized formulation maintains >90% tensile strength after 2,000 hours of accelerated weathering (ISO 4892-2) |

“EVERPLAST Industrial delivers engineered solutions tailored to your industry’s demands. From automotive interior trim to logistics pallets and construction site signage, our corrugated polypropylene sheets meet rigorous performance standards while optimizing your supply chain costs.”

Request a custom sample today to validate performance for your specific application.

📧 [email protected] | 📞 +86 757 8888 9999 | 🌐 www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.