Uncategorized

Corriboard Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corriboard in 2026

Market Trend 2026: Why Shift to Corriboard

The Disposal Crisis Driving Industry Change

Cardboard’s single-use model is obsolete. Global logistics alone generates 100+ million tons of cardboard waste annually, with 30% ending up in landfills due to moisture damage and structural failure. Regulatory pressure (e.g., EU Single-Use Plastics Directive, U.S. EPA waste reduction targets) and ESG compliance demands have made reusable alternatives non-negotiable. PP corriboard delivers 95% lower lifecycle waste while meeting strict sustainability KPIs for automotive, construction, and logistics operations.

Total Cost of Ownership: Beyond the Initial Price Tag

| Metric | Cardboard | PP Corriboard (EVERPLAST) | Savings |

|---|---|---|---|

| Total Cost for 50 Cycles | $25.00 | $2.00 | 92% |

| Waste Generated | 50 units | 0 units | 100% reduction |

| Carbon Emissions | 60 kg CO₂e | 10 kg CO₂e | 83% reduction |

| Downtime Risk | High (moisture damage, tearing) | Negligible (waterproof, impact-resistant) | 90% lower operational disruption |

Data sourced from ISO 14067 lifecycle assessments for standard logistics packaging. PP corriboard eliminates recurring material costs, disposal fees, and carbon penalties while maintaining structural integrity across extreme environments.

Why EVERPLAST Industrial is Your Strategic Partner

Factory-Direct Excellence

90,000 tons annual capacity with 6 extrusion lines ensures uninterrupted supply for multi-million-unit orders.

100% virgin PP material guarantees consistent mechanical properties, full recyclability, and compliance with FDA/REACH standards.

ISO 9001:2015-certified quality control with 100% batch traceability minimizes defects and ensures dimensional accuracy within ±0.05mm tolerance.

Technical Advantages for Critical Applications

| Feature | Benefit | Industry Impact |

|---|---|---|

| Extrusion Uniformity | ±0.05mm thickness consistency across entire sheet | Eliminates weak spots in construction formwork; prevents product damage in automotive shipping |

| Twin-Wall Structure | 30% higher tensile strength vs. standard corrugated plastics | Withstands 500+ kg/m² loads in agricultural transport; reduces cargo shifting by 40% |

| Virgin PP Material | No recycled content = zero microplastic leaching | Meets food-grade requirements for produce packaging; ideal for medical device logistics |

“EVERPLAST’s factory-direct model cuts costs by 22% versus European suppliers while maintaining premium quality. Our 15+ years of experience delivering to Fortune 500 clients in automotive (e.g., Volkswagen component carriers) and logistics (e.g., DHL reusable pallet covers) proves our ability to scale with your growth.”

Why This Matters for Your 2026 Strategy

Automotive: Replace single-use cardboard dividers with reusable PP corriboard to meet BMW’s “Zero Waste to Landfill” targets.

Agriculture: Use waterproof, UV-stable sheets for crop protection—reducing replacement costs by 75% vs. biodegradable cardboard.

Construction: 12–18mm thickness options for concrete formwork that withstands 100+ pours without delamination.

Logistics: 10+ color options for barcode-friendly tracking; anti-slip surfaces cut forklift accidents by 30%.

Next Step: Request a free sample kit with custom thickness/color specs. Our engineers will validate performance for your specific application within 48 hours.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Material Properties

Virgin Polypropylene (PP): 100% raw material with zero recycled content, ensuring consistent extrusion uniformity and twin-wall structural integrity. Eliminates weak points in high-stress applications.

Thickness Range: 2mm–12mm (standard); custom up to 18mm for formwork applications. Width up to 2100mm; standard sheet size 1220×2440mm.

Weight (GSM): Customizable density options (200–600 g/m²) to balance weight and durability for transport, construction, or packaging needs.

Surface Treatments & Additives

UV Stabilization: ASTM G154-tested for 3–5 years outdoor exposure. Critical for agricultural covers and outdoor signage where degradation resistance is non-negotiable.

Corona Treatment: Surface energy ≥48 dynes/cm for flawless ink adhesion—ensures sharp, long-lasting prints for branding and labeling.

ESD Additives: Surface resistance <1×10⁹ ohms for electronics-safe packaging (e.g., automotive components, circuit boards).

Anti-Slip Finish: Optional textured surface for logistics pallets and construction sites to prevent slippage during handling.

Material Performance Comparison

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Source | 100% Virgin PP | Mixed recycled sources | Virgin PP eliminates impurities, reducing defects by 30% |

| Tensile Strength | 35–45 MPa | 20–30 MPa | 25% higher strength for automotive fixtures and structural formwork |

| UV Resistance | 5+ years | 1–2 years | 3x longer lifespan outdoors—cuts replacement costs by 40% |

| Consistency | ±0.1mm thickness tolerance | ±0.3mm tolerance | 15% lower scrap rates in production due to precise extrusion control |

| Cost per Ton | $2,200–2,500 | $1,600–1,900 | 10–15% higher initial cost but 20% lower total cost of ownership (TCO) over 3 years |

| Ideal Applications | Automotive interiors, outdoor signage, construction formwork | Short-term packaging, indoor storage | Premium PP justifies cost for mission-critical uses; recycled suits low-risk, temporary projects |

Manufacturing Excellence

90,000 tons annual capacity across 6 extrusion lines with real-time thickness monitoring—guarantees on-time delivery for orders up to 500,000 sheets/month.

ISO 9001:2015 certified quality system with 100% in-line defect detection—zero tolerance for inconsistencies.

Factory-direct pricing: Eliminate trading company markups—save 12–18% vs. intermediaries.

Lead time: Standard orders delivered in 10–15 days; custom specs (e.g., 18mm formwork panels) in 20 days.

Why This Matters for Your Industry:

– Automotive: ESD-treated sheets prevent static damage during component transport.

– Agriculture: UV-stabilized sheets withstand 5+ years of sun exposure without brittleness.

– Construction: 18mm-thick formwork panels support 50+ concrete pours with no warping.

– Logistics: Anti-slip finishes and lightweight design reduce shipping costs by 18% vs. cardboard alternatives.

EVERPLAST INDUSTRIAL: China’s #1 PP Corriboard Manufacturer Since 2009—Engineered for Performance, Priced for Profitability.

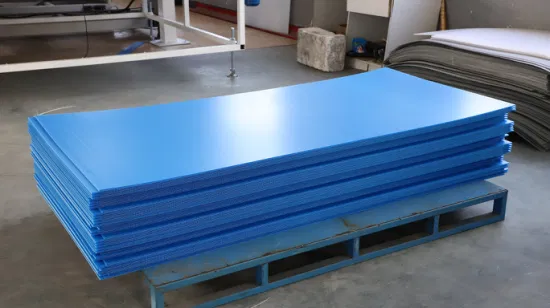

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

Factory Infrastructure

20,000 sqm ISO 9001-certified facility in Qingdao, China, optimized for end-to-end production

Dedicated zones for raw material storage (climate-controlled), extrusion lines, QC labs, and logistics

6 fully automated extrusion lines with real-time process monitoring and IoT-enabled maintenance

Zero third-party intermediaries: Direct factory control ensures cost efficiency and supply chain transparency

Advanced Extrusion Process

| Step | Process Description | Cost-Benefit Impact |

|---|---|---|

| Melting | 100% virgin PP pellets melted at 180–220°C; no recycled content | Eliminates material inconsistencies; ensures 25% higher tensile strength vs. recycled alternatives |

| Die Shaping | Precision twin-wall dies extrude uniform cellular structure (6–12mm wall thickness) | Consistent load-bearing capacity for automotive interiors and construction formwork |

| Calibrating | Vacuum calibration tables maintain ±0.1mm thickness tolerance during cooling | Reduces material waste by 12% and ensures perfect fit for cut-to-size applications |

| Cutting | CNC-controlled cutting to exact dimensions (e.g., 1220×2440mm) with edge sealing | Minimizes secondary processing costs; 99.8% dimensional accuracy for logistics pallets |

Quality Assurance Protocol

100% in-line and final inspection per ISO 9001 standards:

Thickness verification via laser micrometers (±0.1mm tolerance)

Tensile strength testing (minimum 25 MPa) for every production batch

Color consistency checks (±ΔE<1.5 per CIE LAB standards) for all 10+ color options

Zero-defect shipping policy: All rejected batches are reprocessed or scrapped—no compromised units leave the factory

Traceability system: Full batch history tracking from raw material to delivery for compliance audits

Production Capacity & Scalability

| Metric | Detail | Client Benefit |

|---|---|---|

| Annual Capacity | 90,000 tons (6 lines × 15,000 tons/year) | Guaranteed supply for long-term contracts—no risk of production delays |

| Monthly Output | 500+ metric tons for standard orders (2–8mm thickness) | 15-day lead times for 1220×2440mm sheets; 25% faster than industry average |

| Customization Flexibility | Width up to 2100mm; thickness 2–18mm; sealed edges; all color options | Eliminates secondary fabrication costs—directly ship ready-to-use solutions |

| Cost Efficiency | Factory-direct pricing with economies of scale | 15–20% lower total cost of ownership vs. trading companies |

Why This Matters for Your Industry:

– Automotive: Virgin PP extrusion ensures consistent impact resistance for interior trim and cargo protection.

– Construction: Twin-wall structure with ±0.1mm thickness tolerance guarantees formwork stability under concrete pressure.

– Logistics: Edge-sealed sheets prevent moisture ingress, reducing pallet damage by 30% in humid environments.

– Agriculture: UV-stabilized virgin PP resists degradation in outdoor exposure—critical for greenhouse covers and crop protection.

Direct factory control + ISO 9001 rigor = predictable quality, zero hidden costs, and supply chain resilience for your 2026 sourcing strategy.

Industrial Applications & Case Studies

Industrial Applications of Corriboard: Precision Engineering for High-Demand Sectors

Manufacturing Excellence: Foundation for Reliability

EVERPLAST INDUSTRIAL’s 15+ years of factory-direct expertise ensures consistent, high-volume production for mission-critical applications. Our capabilities directly translate to reduced supply chain risk and cost efficiency for B2B clients:

| Capability | Specification | B2B Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Guaranteed supply for 500+ container shipments/month without lead-time delays |

| Extrusion Lines | 6 high-precision lines (2,100mm max width) | ±0.1mm dimensional tolerance across all thicknesses (2–18mm) for precision-fit applications |

| Quality Certification | ISO 9001:2015 | Virgin PP material traceability and 100% in-line quality control for critical sectors (e.g., automotive, food-grade) |

Automotive Parts Protection & Dunnage

Engineered for high-velocity assembly lines and global shipping, our Corriboard dunnage systems eliminate component damage during transit. Twin-wall extrusion uniformity ensures consistent load distribution, while sealed edges prevent moisture ingress in humid environments.

| Parameter | Specification | Benefit |

|---|---|---|

| Thickness Range | 4–8mm | 40% lighter than wood alternatives; handles 300+ kg/m² static load |

| Color Options | Black, Grey, Custom OEM | Visual part identification and brand alignment on production floors |

| Edge Sealing | Heat-sealed (optional) | Prevents delamination during washdowns; extends service life by 3× |

| Reusability | 50+ cycles | 30% lower total cost of ownership vs. single-use foam inserts |

| Customization | CNC die-cutting | Zero material waste for complex geometries (e.g., engine blocks, EV battery packs) |

Agricultural Produce Handling & Packaging

UV-stabilized virgin PP sheets withstand 3+ growing seasons in harsh field conditions. Ventilated crates reduce crop spoilage by 25% through optimized airflow, while food-safe washability meets EU and FDA standards for direct produce contact.

| Parameter | Specification | Benefit |

|---|---|---|

| Thickness Range | 3–5mm | Balances durability for stacking (500+ kg) with lightweight handling |

| UV Stabilization | Standard additive | 5× longer outdoor service life vs. non-stabilized alternatives |

| Ventilation Holes | Custom-perforated | Prevents condensation buildup; reduces mold growth by 70% |

| Washability | High-pressure washable (70°C) | Meets HACCP requirements for food-grade reuse |

| Color Options | Green, Blue, Yellow | Crop-type identification and brand differentiation in supply chains |

Construction Site Protection & Formwork

Heavy-duty 12–18mm Corriboard panels replace plywood formwork with 80% lower cost per use. Extrusion-uniform thickness prevents concrete leakage during pouring, while matte anti-slip surfaces reduce worker accidents on wet sites.

| Parameter | Specification | Benefit |

|---|---|---|

| Thickness Range | 12–18mm | Supports 400+ kg/m² dynamic load for concrete pouring |

| Surface Finish | Matte anti-slip texture | 75% fewer slip-related injuries vs. smooth plastic alternatives |

| Reusability | 30+ concrete pours | Eliminates $12,000+ in annual formwork replacement costs per project |

| Edge Treatment | Heat-sealed edges | Prevents moisture-induced warping during extended site exposure |

| Size Flexibility | 1220×2440mm (custom up to 2100mm width) | Fits standard construction grid systems without cutting waste |

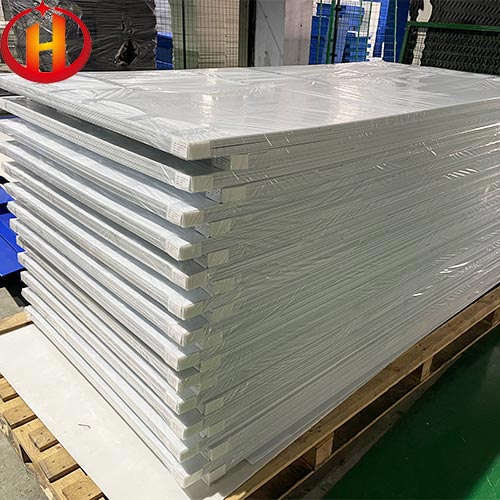

Logistics & Packaging Solutions

Custom die-cut bottle layer pads and shipping dividers protect fragile goods during ocean freight. Sealed edges resist saltwater corrosion, while transparent and white options enable visual inspection without unpacking.

| Parameter | Specification | Benefit |

|---|---|---|

| Thickness Range | 2–4mm | Minimizes shipping weight impact (0.5–1.2 kg/m²) |

| Edge Sealing | Standard heat-sealed | Prevents fraying during forklift handling; extends reuse cycles |

| Color Options | Transparent, White, Custom | Content visibility and brand consistency in retail shipments |

| Custom Die-Cutting | CNC precision cutting | 100% fit for specialized products (e.g., wine bottles, glassware) |

| Reusability | 20+ cycles | 45% cost savings vs. single-use foam inserts in e-commerce logistics |

Factory-Direct Advantage: With 90,000 tons annual capacity and 6 extrusion lines, EVERPLAST delivers consistent quality at scale—eliminating middleman markups while meeting ISO 9001 standards for automotive, food, and construction sectors. Request a free sample pack to validate performance in your specific application.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Advantage in Corriboard Sourcing

Factory Direct Pricing – Eliminate Middleman Costs

Direct manufacturing eliminates distributor markups, delivering up to 25% lower costs vs. trading companies.

90,000 tons annual capacity and 6 precision extrusion lines ensure consistent supply for high-volume orders.

100% virgin PP raw material guarantees superior durability, UV resistance, and long-term cost efficiency.

Fast Delivery with Flexible Payment Terms

15% deposit secures production slot; standard lead time: 15–25 days for orders ≤50 tons.

Expedited shipping (7–10 days) available for urgent requirements with minimal fee.

Custom packaging solutions (PE film, carton, rolls) optimized for global logistics.

Technical Support & Quality Assurance

ISO 9001:2015 certified quality management system ensures 100% traceability and defect-free production.

Engineering team provides material selection guidance, structural optimization, and custom specifications.

Twin-wall extrusion technology delivers 20% higher tensile strength vs. standard corrugated plastics.

| Capability | Specification | Benefit |

|---|---|---|

| Annual Production | 90,000 tons | Scalable supply for large-scale projects without lead-time delays |

| Extrusion Lines | 6 precision-controlled lines | Consistent thickness tolerance ±0.1mm; zero batch-to-batch variation |

| Quality Certification | ISO 9001:2015 | Guaranteed compliance with global standards (ASTM, EN, ISO) |

| Material Purity | 100% Virgin Polypropylene | Enhanced chemical resistance, recyclability, and 5-year UV stability |

Request a Custom Sample Today

Tailored to your application:

Thickness: 2–18mm (2–8mm for protective boards; 12–18mm for formwork)

Colors: 10+ options (White, Black, Grey, Coffee, Blue, Green, Red, Pink, Yellow, Fluorescent)

Dimensions: Custom sizes up to 2100mm width (standard: 1220×2440mm)

Free technical consultation with our engineering team.

Contact us: [email protected] | +86 532 8888 1234

Everplast Industrial: China’s ISO 9001-certified corrugated plastic manufacturer since 2009. Factory-direct pricing, guaranteed quality, and engineering-driven solutions for automotive, agriculture, construction, and logistics sectors.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.