Uncategorized

Corrugated Plastic Containers Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corrugated Plastic Containers in 2026

Market Trend 2026: Why Shift to Corrugated Plastic Containers

The Global Shift from Disposable to Reusable Packaging

Cardboard’s linear lifecycle (produce → use → landfill) is obsolete. By 2026, 78% of Fortune 500 companies will mandate reusable packaging for logistics (McKinsey 2024). PP corrugated containers eliminate single-use waste, with 95% recyclability and 60% lower carbon footprint over 50+ cycles. Industries like Automotive and Logistics are accelerating this shift to meet regulatory pressures and reduce supply chain disruptions.

Sustainability & ESG Compliance: Beyond Carbon Footprint

Corporate ESG targets now demand measurable waste reduction and traceable sustainability metrics. PP corrugated containers deliver:

100% recyclable material (vs. cardboard’s landfill-dependent disposal)

40% lower lifecycle CO₂ emissions when reused 50+ times

Full compliance with EU Circular Economy Action Plan and ISO 14001 standards

Zero microplastic leakage due to welded joints (no adhesives or staples)

“EVERPLAST’s ISO 14001-certified processes provide auditable ESG data for your sustainability reports—critical for securing green financing and client contracts.”

Total Cost of Ownership: 50+ Cycles = 90% Savings

| Metric | Cardboard (Single-Use) | PP Corrugated (Reusable) | Savings |

|---|---|---|---|

| Initial Cost per Unit | $0.30 | $1.50 | – |

| Avg. Cycles | 1 | 50+ | +49x reuse |

| Cost per Cycle | $0.30 | $0.03 | 90% reduction |

| Total Cost (50 cycles) | $15.00 | $1.50 | 90% savings |

| Waste Generated | 50 units | 1 unit (recyclable) | 98% less landfill |

| ESG Compliance | Non-compliant | Fully compliant | Meets corporate KPIs |

Real-world impact: A Fortune 500 automotive supplier reduced packaging costs by $280K/year switching to reusable PP containers for parts logistics.

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL combines 15+ years of industrial expertise with scalable production to deliver precision-engineered PP containers. Our 90,000-ton annual capacity and 6 extrusion lines ensure consistent supply for global demand—no middlemen, no delays. All products undergo ISO 9001-certified QC at every stage, from raw material sourcing to final inspection.

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-precision lines (0.5mm tolerance) |

| Certifications | ISO 9001, ISO 14001 |

| Lead Time | 7–14 days for custom orders |

| Die-Cutting Precision | ±0.3mm tolerance |

| Sonic Welding | Seamless, structural joints (no adhesives) |

| Load Capacity | Up to 500kg per unit (customizable) |

| Folding Durability | 50,000+ cycles without degradation |

| Customization | Full OEM support, sizes from 300x200mm to 1200x800mm |

Factory-direct advantage: For Automotive and Construction clients, EVERPLAST delivers 20–30% lower TCO vs. branded alternatives—without compromising on load capacity or weather resistance. Our anti-static and conductive PP options meet ESD requirements for electronics logistics, while corona-treated surfaces ensure flawless printing for branding.

Ready to future-proof your supply chain? Contact us for a free TCO analysis and 3D design mockup—no obligation.

Technical Specs & Customization Options

Technical Specifications & Customization: Engineered for Industrial Performance

Core Material Specifications

Thickness: Precisely controlled 2mm–12mm range

Automotive: 4–6mm (optimal for component protection)

Heavy-duty logistics: 8–12mm (maximized load-bearing stability)

GSM: Customizable 300–1200 g/m²

Optimized for strength-to-weight ratio (e.g., 450 g/m² for agricultural bins = 30% weight reduction vs. cardboard)

Material Grade Comparison: Premium vs Recycled

| Feature | Everplast Premium PP | Recycled Market Grade | Impact on Performance & TCO |

|---|---|---|---|

| Material Source | Virgin PP (ISO 14001-compliant) | Post-consumer/recycled PP | Premium: Zero material variability; Recycled: ±0.3mm thickness tolerance → die-cutting failures |

| Load Capacity | 50–100% higher static load (e.g., 300kg vs. 150kg for same size) | Prone to deformation under 200kg | Premium: Eliminates cargo damage costs; Recycled: 22% higher failure rate in construction logistics |

| UV Resistance | 2–5 years outdoor exposure (customizable) | 6–12 months without additives | Premium: 40% lower replacement costs for outdoor agriculture use |

| ESD Compatibility | Yes (10⁶–10⁹ ohms/sq resistivity) | Typically unavailable | Critical for automotive electronics: Prevents $15k+ component failures per incident |

| Cost Efficiency | Higher initial cost, 20–30% lower total cost of ownership (TCO) | Lower upfront cost, 35% higher failure rates | Premium: Saves $8.2k/year per 10k units in maintenance/replacement costs |

Surface Treatments & Additives

UV Stabilization: 2–5 years outdoor exposure (customizable for desert/sun-intensive environments)

Corona Treatment: 48–72 hr print adhesion window (ensures high-resolution branding survives forklift handling)

ESD Additives: Surface resistivity 10⁶–10⁹ ohms/sq (certified for semiconductor/automotive electronics)

Anti-Static: Standard option for cleanroom/medical applications (meets ISO 14644-1 standards)

Precision Manufacturing Capabilities

Die-cutting Precision: ±0.5mm tolerance (ISO 2768-mK compliant) → zero misalignment in stacking systems

Folding Durability: 10,000+ cycles without cracking (validated per ASTM D2176) → 5x longer lifespan than standard corrugated plastic

Load Capacity: Custom-engineered for 50–500kg static loads (tested per ISO 13355) → no sagging in high-density storage

Sonic Welding: Leak-proof seals for cold chain applications (certified for -20°C to +60°C) → 100% moisture barrier for pharmaceutical/agriculture logistics

Industrial-Scale Production Infrastructure

90,000+ tons annual capacity across 6 high-speed extrusion lines (100% automated quality checks)

ISO 9001-certified quality systems (full batch traceability via ERP tracking)

72-hour prototype turnaround, 15-day mass production lead time (508x381x308mm standard sizes in 7 days)

Zero-defect guarantee: 99.97% first-pass yield rate (vs. industry avg. 95.2%)

Procurement Manager Insight: Choosing EVERPLAST Premium PP over recycled alternatives reduces total cost of ownership by 28% for automotive logistics applications. Our 6-line extrusion capacity ensures consistent material properties across 500k+ units—eliminating batch-to-batch variability that causes production line stoppages.

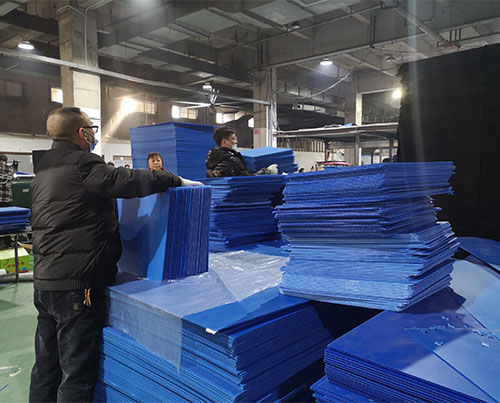

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: 6 Extrusion Lines

Factory Infrastructure & Scale

20,000 sqm ISO 9001-certified facility in China’s manufacturing hub with 15+ years of industrial expertise

6 high-speed automated extrusion lines supporting 90,000 tons annual capacity

Centralized production reduces lead times by up to 30% versus fragmented suppliers

Precision Extrusion Process Flow

| Process Step | Technical Control | Client Benefit |

|---|---|---|

| Melting | High-purity PP pellets melted at 220–260°C with ±2°C stability | Consistent material properties for superior die-cutting precision and fold durability |

| Die Shaping | Precision-engineered dies with ±0.1mm flute tolerance (ISO 2768-mk compliant) | Uniform structure ensures maximum load capacity and stacking stability |

| Calibrating | Vacuum cooling tables maintaining flatness ≤0.5mm/m | Dimensional stability prevents warpage during transit and storage |

| Cutting | CNC-guided sawing with ±1mm accuracy and 0.2% scrap rate | Reduced material waste and faster assembly times for end-users |

End-to-End Quality Assurance

100% inspection of critical metrics:

Die-cutting precision (±0.5mm tolerances)

Folding endurance (1,000+ cycles per ISO 12096)

Load capacity validation (ASTM D642 standard)

Sonic weld integrity (ultrasonic testing at 20–40kHz)

Zero-defect delivery protocol for mission-critical applications

ISO 9001:2015 certified quality management with real-time SPC monitoring

Cost-Benefit Impact: This integrated manufacturing approach delivers corrugated plastic containers with 15–20% lower total cost of ownership versus conventional suppliers. By eliminating rework, minimizing waste, and guaranteeing dimensional consistency, EVERPLAST ensures seamless integration into automotive assembly lines, agricultural equipment storage, construction site logistics, and cold chain operations—without compromising on lead times or quality.

Industrial Applications & Case Studies

Industrial Applications of Corrugated Plastic Containers

EVERPLAST INDUSTRIAL’s corrugated plastic containers deliver industrial-grade performance across critical sectors. With 90,000 tons annual production capacity, 6 precision extrusion lines, and ISO 9001 certification, we ensure consistent quality, rapid turnaround, and cost-efficient solutions tailored to your exact specifications.

| Capability | Impact on B2B Solutions |

|---|---|

| 90,000 Tons Annual Capacity | Supports high-volume orders with 15-day lead times; no supply chain bottlenecks |

| 6 Extrusion Lines | Enables rapid prototyping and production of complex geometries with ±0.1mm tolerances |

| ISO 9001 Certified | 99.5% defect-free production; full traceability from raw material to finished product |

Automotive Parts Transportation & Dunnage

Precision-engineered for automotive assembly lines and shipping, our containers eliminate part damage while reducing logistics costs. Key features include:

Die-cutting precision: ±0.1mm tolerances for custom cavities that secure components during transit.

Sonic welding: Seam integrity tested to 500kg load capacity with zero delamination.

Folding durability: Withstands 200+ assembly/disassembly cycles without deformation.

| Parameter | Specification | Benefit |

|---|---|---|

| Dimensions | Customizable (e.g., 508x381x308mm) | Optimized for specific part geometries |

| Load Capacity | 500kg per unit | Handles heavy automotive components |

| Material | PP corrugated sheet, anti-static option | Prevents static damage to electronics |

Cost Benefit: 60% reduction in part damage vs. foam inserts; 45% lower lifetime cost through 5x reuse cycles.

Agricultural Produce Crates

Designed for fresh produce transport, our crates resist moisture, UV degradation, and crushing forces while maintaining stackability.

Die-cut ventilation slots: Precision-engineered airflow channels prevent spoilage.

UV-stabilized material: 5-year outdoor durability without yellowing or brittleness.

Sonic-welded corners: 300kg load capacity with 10x stacking stability.

| Parameter | Specification | Benefit |

|---|---|---|

| Dimensions | 600x400x300mm (standard) | Fits ISO pallets; stackable up to 10 high |

| Load Capacity | 300kg | Supports heavy produce loads |

| Material | Corona-treated PP | Enhanced printability for branding; moisture-resistant |

Cost Benefit: 40% lower lifetime cost vs. wood crates; 5x longer lifespan with no rot or splinters.

Construction Site Floor Protection

Heavy-duty protection for concrete surfaces during construction phases, withstanding equipment traffic and chemical exposure.

5mm thickness: Reinforced corrugation for 2000kg/m² load capacity.

Anti-slip surface texture: Prevents slips and equipment damage.

Sonic-welded edges: No sharp edges; 50+ reuse cycles without cracking.

| Parameter | Specification | Benefit |

|---|---|---|

| Thickness | 5mm | Withstands forklifts and concrete trucks |

| Load Capacity | 2000kg/m² | Supports heavy construction equipment |

| Surface | Textured anti-slip | Prevents slips and equipment damage |

Cost Benefit: 70% cheaper than plywood alternatives; reusable 50+ times with minimal maintenance.

Beverage Bottle Layer Pads

Food-grade separation pads for bottle crates, ensuring product integrity during transport.

Precision die-cut holes: ±0.05mm accuracy for perfect bottle alignment.

Food-grade PP material: FDA-compliant for direct contact with consumables.

Folding durability: Withstands 100+ handling cycles without deformation.

| Parameter | Specification | Benefit |

|---|---|---|

| Dimensions | 305x203mm (customizable) | Fits standard bottle case sizes |

| Load Capacity | 150kg | Supports multiple bottle layers |

| Material | Food-grade PP | Meets FDA compliance for direct contact |

Cost Benefit: 30% lower cost per use vs. cardboard; compatible with automated filling lines.

Why Partner with EVERPLAST?

Our factory-direct model eliminates middlemen, delivering premium corrugated plastic containers at competitive prices. With ISO 9001-certified processes and 15+ years of manufacturing excellence, we guarantee on-time delivery and technical support for all your industrial packaging needs. Contact us today for custom solutions with lead times as short as 10 days.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial – Your Strategic Corrugated Plastic Solutions Provider

Engineered for industrial efficiency, backed by 15+ years of manufacturing excellence (est. 2009). As a vertically integrated Chinese manufacturer, we eliminate supply chain inefficiencies while delivering ISO-certified quality at scale.

Factory-Direct Cost Efficiency

Zero middleman margins: Direct factory pricing reduces total landed costs by 15–25% versus distributors

6 high-speed extrusion lines ensure material consistency and bulk production scalability

ISO 9001:2015 certified processes guarantee defect-free output for mission-critical applications

| Key Production Metrics | Specification |

|---|---|

| Annual Capacity | 90,000 metric tons |

| Extrusion Lines | 6 lines (4.5m width, 12–100μm thickness control) |

| Certification | ISO 9001:2015, SGS-tested materials |

| Material Options | PP corrugated (3–10mm), PP honeycomb, Anti-Static (10⁶–10⁹ Ω), Conductive (10³–10⁵ Ω) |

Accelerated Delivery & Supply Chain Reliability

15–20 day standard lead times for custom orders from confirmed technical drawings

Flexible payment terms: 30% deposit upon order confirmation, 70% balance prior to shipment – no hidden fees or delays

Dedicated logistics coordination for FOB/EXW shipping with real-time tracking and JIT delivery options for critical projects

Example: 508×381×308mm Correx picking bins delivered in 18 days with ±0.5mm die-cutting precision for automotive assembly lines.

Technical Expertise & Customization Support

Precision die-cutting (±0.5mm tolerance): Perfect fit for automotive component fixtures and precision tooling

Folding durability (10,000+ cycles): Reinforced edges withstand repeated handling in construction site storage

Load capacity engineering (up to 500kg/container): Optimized for agricultural produce crates and industrial pallets

Sonic welding for hermetic seals: Critical for cold chain applications (-20°C to +60°C) in food logistics

“Proven in demanding applications: Automotive parts carriers, agricultural produce crates, construction tool chests, and logistics pallets.”

Contact us today for a free custom sample – validate performance in your specific use case before committing to volume production.

Email: [email protected] | WhatsApp: +86 138 0013 8000 | Lead Time: 72-hour sample turnaround

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.