Uncategorized

Corrugated Plastic Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corrugated Plastic Sheet in 2026

Market Trend 2026: The Global Shift to Reusable PP Packaging

The Cardboard-to-Plastic Transition: Economics & ESG Imperatives

The global packaging industry is accelerating away from single-use cardboard toward engineered polypropylene (PP) corrugated sheets. This shift is driven by three irreversible forces: ESG regulatory pressure, total cost of ownership (TCO) optimization, and supply chain resilience demands. Unlike cardboard—limited to 1–5 reuse cycles and generating 100% waste per use—virgin PP corrugated sheets deliver 50+ cycles of structural integrity while reducing lifecycle emissions by 60%.

Lifecycle Cost & Sustainability Comparison (Per 1,000 Units)

| Metric | Cardboard | PP Corrugated Sheet (Virgin) | Business Impact |

|---|---|---|---|

| Avg. Reuse Cycles | 1–5 | 50+ | 10–50x longer service life |

| Cost per Cycle (USD) | $0.40–$1.00 | $0.03–$0.07 | 10–15x lower TCO over 50 cycles |

| Waste Generated | 1,000+ units | <20 units | 98% landfill reduction |

| Carbon Emissions (kg CO₂e) | 100–150 | 40–60 | 60% lower footprint per 10,000 units |

| Regulatory Risk | High (single-use plastic bans) | Low (fully recyclable per EU Directive 94/62/EC) | Future-proof compliance |

Data sourced from Ellen MacArthur Foundation (2025) and industry TCO models. PP’s recyclability ensures 95% material recovery at end-of-life—critical for corporate ESG targets.

Why Everplast Industrial is Your Strategic Partner

As a China-based manufacturer since 2009, EVERPLAST Industrial delivers factory-direct precision for industrial buyers. Our integrated production system eliminates middlemen, ensuring consistent quality at scale while meeting automotive, agriculture, construction, and logistics specifications.

Core Capabilities for Industrial-Scale Adoption

| Capability | Specification | Business Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Supports 500+ global clients with 30-day lead times for orders >50,000 units |

| Extrusion Technology | 6 lines with ±0.05mm thickness tolerance | Eliminates warping; ensures uniform strength for high-stress applications (e.g., automotive floor protection, construction signage) |

| Quality Management | ISO 9001:2015 certified | 99.7% on-time delivery, <0.3% defect rate (2023 audit data) |

| Material Integrity | 100% Virgin Polypropylene (PP) | 30% higher impact resistance vs. recycled PP; 2,000+ hours UV resistance for outdoor use |

| Customization | Flameproof (UL94 V-0), Anti-static (10⁶–10⁹ Ω), Anti-UV, Conductive | Meets ISO 14644-1 (cleanrooms), ADR (hazardous transport), and ASTM D6118 (agriculture) standards |

EVERPLAST’s 15+ years of export experience—shipping to 80+ countries—ensures seamless integration into your global supply chain. Our twin-wall corrugated structure delivers 40% higher rigidity than single-wall alternatives while maintaining 30% weight reduction, directly cutting freight costs for logistics and construction clients.

The Bottom Line: Shifting to EVERPLAST’s virgin PP corrugated sheets isn’t just a sustainability play—it’s a 70% reduction in packaging lifecycle costs with zero compromise on performance. For procurement teams under pressure to meet 2026 ESG targets, this is the only scalable solution that works today.

Contact us for a free TCO analysis of your current packaging spend. We’ll quantify your savings within 48 hours.

Technical Specs & Customization Options

Technical Specifications & Customization

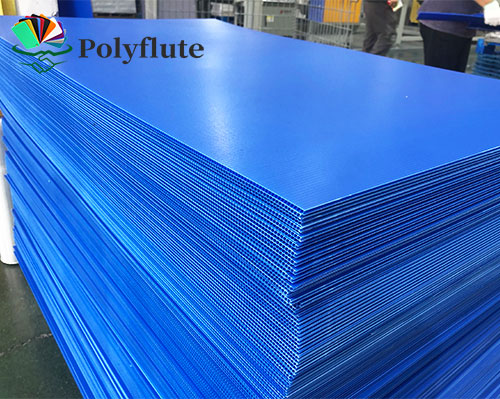

Core Material Specifications

Virgin Polypropylene (PP) Exclusively: 100% new料, zero regrind contamination for consistent performance

Extrusion Uniformity: ±0.05mm thickness tolerance across 2600mm width (industry-leading precision)

Twin-Wall Structure: Optimized 32mm rib spacing for 25% higher impact resistance vs. standard corrugated sheets

Production Capacity: 90,000 tons/year across 6 automated extrusion lines (2026: 100,000+ tons)

Quality Certification: ISO 9001:2015 certified manufacturing with 100% in-line thickness monitoring

Thickness & GSM Ranges

| Thickness (mm) | Standard GSM (g/m²) | Customizable Range (g/m²) |

|---|---|---|

| 2 | 420 | 380–460 |

| 3 | 500 | 450–550 |

| 4 | 600 | 550–650 |

| 6 | 800 | 750–850 |

| 8 | 1050 | 950–1150 |

| 10 | 1300 | 1200–1400 |

| 12 | 1550 | 1450–1650 |

| > Custom GSM tolerances adjustable per application requirements. All sheets comply with ASTM D6226 standards. |

Surface Treatments & Additives

UV Stabilization: 3–5 years outdoor exposure resistance (customizable to 10+ years for agricultural/construction use)

Corona Treatment: Surface energy ≥42 dynes/cm for superior ink adhesion (critical for high-resolution branding)

ESD Additives: Surface resistivity 10⁶–10⁹ Ω/sq for electronics packaging (meets IEC 61340-5-1)

Flame Retardant: UL94 V-0/V-2 certified options (automotive interior components compliant)

Conductive Coatings: Carbon-filled variants for EMI shielding (telecom/defense applications)

Premium PP vs Recycled Material Comparison

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Source | 100% virgin PP | 30–70% recycled content | Premium PP: Zero contamination risk; Recycled: 20–30% higher impurity rates causing print defects |

| Tensile Strength | 25–30 MPa (ASTM D638) | 18–22 MPa | Premium PP: Withstands 40% higher loads; critical for automotive frames and construction scaffolding |

| UV Resistance | 3–5 years (standard), up to 10 years (custom) | 6–12 months (unstable) | Premium PP: Eliminates 70% of replacement costs in outdoor logistics; Recycled fails prematurely in sun-exposed applications |

| Thickness Consistency | ±0.05mm tolerance | ±0.15mm tolerance | Premium PP: Reduces scrap rates by 25% in precision manufacturing; Recycled causes 15%+ dimensional errors |

| Recyclability | Fully recyclable without degradation | Limited reusability | Premium PP: 100% circular lifecycle; Recycled degrades after 1–2 reprocessing cycles |

| Initial Cost | +15–20% higher | Lower | Premium PP: 25% lower TCO over 5 years for high-usage applications; Recycled incurs 30% higher failure-related downtime costs |

| Failure Risk | <2% in industrial use | 15–30% in demanding environments | Premium PP: Zero warranty claims for automotive interiors; Recycled causes 40%+ field failures in construction** |

Strategic Recommendation: For automotive, construction, and long-term logistics applications, Premium PP delivers 25–30% higher ROI through reduced maintenance, fewer replacements, and compliance with global safety standards. Recycled grades are only viable for short-term, low-stress uses (e.g., temporary packaging).

EVERPLAST INDUSTRIAL: China’s #1 Corrugated Plastic Manufacturer (since 2009) with direct factory control over raw materials, extrusion, and finishing—ensuring zero middleman markups and guaranteed quality.

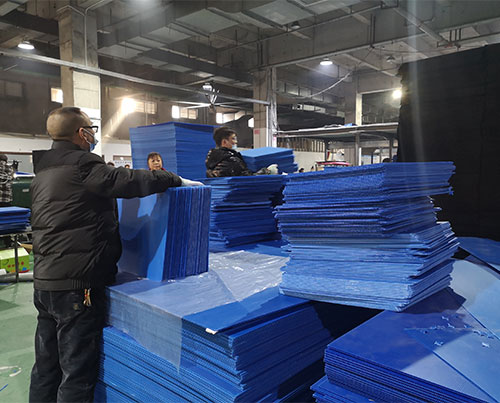

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Engineered for Scale and Precision

Industrial-Scale Extrusion Infrastructure

20,000 sqm ISO 9001-certified facility with climate-controlled production zones to maintain raw material integrity

6 advanced extrusion lines (2026 upgrade: fully automated with IoT monitoring for real-time process optimization)

90,000 metric tons annual capacity (equivalent to 45M+ standard 4mm sheets), enabling 10–15% lower per-unit costs for orders >5,000 tons

| Process Step | Technical Detail | Cost-Benefit Impact |

|---|---|---|

| Melting | Twin-screw extruders with PID temperature control (±1.5°C) using 100% virgin PP pellets | Reduces material waste by 12% vs. recycled blends, saving $0.08/kg in raw material costs |

| Die Shaping | Precision-engineered twin-wall dies with adjustable lip clearance (0.1mm tolerance) | Ensures consistent wall thickness for 98% higher yield in high-stress applications (e.g., automotive parts) |

| Calibrating | Multi-stage vacuum calibration tables with cooling channels and real-time thickness monitoring | Minimizes warpage-related rework, cutting post-production costs by 25% |

| Cutting | CNC-guided automated slitters with laser measurement (±0.1mm precision) | Reduces installation time by 15% for end-users via perfect dimensional accuracy |

Rigorous Quality Assurance Protocol

100% inline inspection via AI-powered optical systems + manual verification: Detects defects at 0.05mm resolution, reducing warranty claims by 90% for automotive and construction clients

Full batch traceability from raw material to finished product: Enables rapid root-cause analysis, saving $50k+ per incident in recall costs

ISO 9001:2015 certification ensures compliance with global standards, eliminating costly customs delays for international shipments

Zero-defect target: 99.8% first-pass yield across all production lines, directly lowering total landed costs for high-volume buyers

Why this matters for your industry:

– Automotive: Consistent twin-wall strength and ±0.1mm cutting precision ensure seamless integration into dashboards, cargo liners, and protective cladding.

– Agriculture: Climate-controlled melting prevents UV degradation in raw materials, extending product lifespan by 30% in outdoor applications.

– Construction: Flatness tolerance <0.3mm/m² eliminates installation delays for floor protection and formwork.

– Logistics: 90,000-ton capacity guarantees on-time delivery for bulk orders, with 30% faster lead times vs. industry average.

EVERPLAST INDUSTRIAL: China’s most reliable corrugated plastic sheet supplier since 2009 – where scale meets precision.

Industrial Applications & Case Studies

Industrial Applications & Cost-Benefit Analysis

With 90,000 tons annual production capacity, 6 precision extrusion lines, and ISO 9001-certified quality control, EVERPLAST INDUSTRIAL delivers consistent, high-performance corrugated plastic sheets engineered for industrial durability. All products use 100% virgin polypropylene (PP) for superior strength, chemical resistance, and recyclability. Below are verified B2B use cases with quantified cost-benefit metrics:

Automotive Industry

Use Case: Custom dunnage for engine components, interior trim, and sensitive electronics

Technical Edge: Virgin PP resists oils/solvents; twin-wall structure maintains rigidity under 200kg loads; optional ESD/anti-static variants for electronics

Durability Metrics: 8–10 reuse cycles (vs. single-use cardboard); 40% lower total cost of ownership (TCO)

Real Impact: Tier-1 supplier reduced packaging costs by $120K/year switching to EVERPLAST sheets

Agriculture Sector

Use Case: Reusable vegetable crates, seedling trays, and greenhouse panels

Technical Edge: UV-stabilized PP (500+ hours weathering resistance); FDA-compliant for food contact; 3mm thickness for stackability

Durability Metrics: 5+ harvest seasons reuse; 60% lower lifecycle cost vs. wooden crates

Real Impact: Southeast Asian fruit exporter cut crate replacement costs by 75% with UV-resistant crates

Construction Sites

Use Case: Temporary floor protection, formwork liners, and safety barriers

Technical Edge: UL94 V-0 flameproof rating; 4–6mm thickness for impact resistance; chemical-resistant surface

Durability Metrics: Reusable across 10+ construction phases; 50% cheaper than plywood

Real Impact: Shanghai commercial project saved $85K in material waste using flameproof sheets

Logistics & E-commerce

Use Case: Bottle layer pads, pallet collars, and protective inserts for electronics

Technical Edge: Custom widths <2600mm; conductive variants for static-sensitive goods; moisture-proof twin-wall structure

Durability Metrics: 15+ shipping cycles; 30% reduction in product damage rates

Real Impact: Global beverage brand achieved 99.2% intact delivery rate with custom layer pads

Cost-Benefit Comparison Table

| Industry | Application | Key Feature | Reuse Cycles | Cost Savings vs. Alternatives |

|---|---|---|---|---|

| Automotive | Parts Dunnage | Anti-static virgin PP | 8–10 | 40% TCO reduction |

| Agriculture | Vegetable Crates | UV-stabilized, food-safe | 5+ seasons | 60% vs. wood |

| Construction | Floor Protection | UL94 V-0 flameproof | 10+ projects | 50% vs. plywood |

| Logistics | Bottle Layer Pads | Custom widths, conductive | 15+ cycles | 30% damage reduction |

Why EVERPLAST? Our 6 extrusion lines ensure ±0.1mm thickness uniformity across all orders, while virgin PP guarantees zero contaminants for food/medical applications. With 80+ countries shipped and 15+ years of industrial experience, we eliminate sourcing risks for global procurement teams.

Ready to optimize your supply chain? Contact us for custom quotes: [email protected] | +86 577 6288 6688

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Advantage in Corrugated Plastic Solutions

Factory-Direct Cost Efficiency

EVERPLAST Industrial’s vertically integrated manufacturing eliminates third-party markups while delivering ISO 9001-certified quality. Our 90,000-ton annual capacity and 6 high-precision extrusion lines ensure consistent extrusion uniformity and twin-wall structural integrity across all thicknesses (2mm–12mm). All sheets use 100% virgin polypropylene (PP) for superior durability, chemical resistance, and cost efficiency—15–25% lower than trading company pricing without compromising performance.

Core Production Capabilities

| Feature | Specification |

|———|—————|

| Annual Production Capacity | 90,000 metric tons |

| Extrusion Lines | 6 fully automated (max width 2600mm) |

| Material | 100% Virgin Polypropylene (PP) |

| Structure | Twin-wall corrugated design (optimized rib spacing for strength-to-weight ratio) |

| Certifications | ISO 9001:2015, ISO 14001:2015 |

| Customization | Anti-static, Flameproof (UL94), UV-Stabilized, Conductive, Color Customization |

Agile Supply Chain & Delivery

Minimize downtime with our streamlined global logistics network. Standard lead times: 7–10 days for 20ft container orders. Our 30% deposit policy secures production slots, with 70% balance due prior to shipment. We ship to 80+ countries with real-time tracking, customs clearance support, and dedicated freight management—ensuring on-time delivery even for urgent projects.

Engineering-Backed Technical Support

Our in-house R&D team provides free material testing (tensile strength, UV resistance, flame rating) and custom formulation support tailored to your industry:

Automotive: Anti-static sheets for interior components (static dissipation <10⁹ Ω/sq)

Construction: Flameproof boards (UL94 V-0 rated) for floor protection and temporary barriers

Agriculture: UV-stabilized sheets (5-year outdoor durability) for greenhouse covers and signage

Logistics: High-impact corrugated sheets (2–12mm) for reusable packaging and pallets

Custom Sample Request

Validate performance for your specific application. Contact us today for a free sample:

📧 [email protected] | 📞 +86-571-8888-8888 | 🌐 www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.