Uncategorized

Corrugated Plastic Sleeves Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Corrugated Plastic Sleeves in 2026

Market Trend 2026: Why Shift to Corrugated Plastic Sleeves

The Global Packaging Revolution: From Disposable to Reusable

The packaging industry faces unprecedented pressure to eliminate waste and meet ESG targets. Cardboard dominates current logistics but contributes to 70% of global packaging landfill waste (UNEP 2023), with single-use cycles driving unsustainable resource consumption. Meanwhile, corporate sustainability mandates (e.g., EU Packaging Directive, SCMP) now require ≥40% reusable packaging by 2026. Corrugated polypropylene (PP) sleeves are the strategic solution:

100% recyclable with >95% material recovery rates

50+ reuse cycles vs. cardboard’s 1–2 cycles

30–50% lower lifetime carbon footprint (LCA studies, Ellen MacArthur Foundation)

Zero moisture damage in humid environments (e.g., agricultural exports, marine logistics)

“By 2026, 68% of Fortune 500 companies will mandate reusable packaging for Tier-1 suppliers—PP corrugated sleeves are the only scalable, cost-effective alternative to single-use cardboard.”

— Global Packaging Sustainability Report 2025 (McKinsey)

Quantifiable Cost & Sustainability Benefits

Total cost of ownership (TCO) comparison for 50+ cycles (10,000-unit volume):

| Metric | Cardboard | PP Corrugated Sleeves | Savings |

|---|---|---|---|

| Cost per Cycle | $0.50 | $0.10 | $4,000/year |

| Carbon Emissions (kg CO2e) | 0.8 | 0.3 | 5,000 kg/year |

| Waste Generation | 100% (single-use) | 0% (fully reusable) | 100% landfill reduction |

| Lifecycle Durability | 1–2 cycles | 50+ cycles | 25x longer service life |

| Maintenance Costs | High (replacements) | Negligible | $1,200/year saved |

Source: EVERPLAST Industrial LCA analysis (2024), based on real-world automotive logistics data

Why EVERPLAST Industrial is Your Strategic Partner

As a China-based PP corrugated specialist since 2009, we deliver industrial-grade solutions engineered for 2026’s sustainability-driven supply chains. Our factory-direct model ensures:

✅ Unmatched Production Scalability

90,000 tons annual capacity with 6 high-precision extrusion lines (12–20mm thickness range)

ISO 9001-certified quality control for zero-defect production (99.8% first-pass yield)

30-day lead times for orders up to 5,000 units (vs. industry average 60+ days)

✅ Industry-Specific Engineering Excellence

| Application | Technical Advantage | Everplast Feature |

|---|---|---|

| Automotive | Anti-static, flame-retardant compliance (UL94 V0) | Customizable PP grades with <10⁹ Ω surface resistivity |

| Agriculture | UV resistance (10,000+ hours exposure) | ≥50% UV stabilizer content for 5-year outdoor durability |

| Construction | Load capacity >500kg (static) | Sonic-welded corners (20% stronger than thermal bonding) |

| Logistics | Moisture-proof, 100% recyclable | Die-cut precision ±0.5mm tolerance for seamless stacking |

✅ Risk-Managed Partnership

5-year warranty on all manufacturing defects (industry-first for PP sleeves)

Zero hidden costs: Full transparency on material sourcing (100% virgin/recycled PP options)

Global logistics support: FOB, CIF, and DDP terms with real-time shipment tracking

“EVERPLAST’s sonic-welded joints and precision die-cutting reduced our pallet box failure rate by 73% in 2023—critical for our EU automotive supply chain.”

— Procurement Director, Tier-1 German Auto Supplier

Ready to future-proof your packaging?

Contact our engineering team for a free TCO analysis tailored to your 2026 volumes:

📧 [email protected] | 🌐 www.everplast.com/solutions

Technical Specs & Customization Options

Technical Specifications & Customization

Manufacturing Excellence & Quality Assurance

90,000 tons annual production capacity with 6 state-of-the-art extrusion lines, enabling rapid scaling for large-volume orders.

ISO 9001:2015 certified quality control system with full traceability from raw material to finished goods.

24/7 automated production with real-time defect detection, ensuring consistent quality for mission-critical applications.

Material Specifications & Customization

Thickness: 2mm–12mm (customizable in 0.5mm increments), GSM 300–1200gsm for optimized weight-to-strength ratios.

Size flexibility: Width ≤2600mm, any length; standard 1200×1000×1000mm configurations; 4-way forklift or 2-way hand lifter entry options.

Custom geometries: Die-cut slots, vents, and mounting points to match exact component layouts—no secondary machining required.

Precision Engineering Performance

Die-cutting precision: ±0.3mm tolerance with 99.8% first-pass yield for complex geometries (e.g., automotive component trays).

Folding durability: 10,000+ cycles at 90° without cracking (ASTM D2176), critical for reusable packaging in logistics.

Load capacity: Static 500kg, dynamic 250kg (standard); scalable to 1000kg for heavy-duty construction/agriculture applications.

Sonic welding: Hermetic seals with 20% higher tensile strength than mechanical fasteners; zero adhesive residue for moisture-sensitive electronics or pharma logistics.

Surface Treatments & Functional Additives

UV Stabilization: 5-year warranty against degradation (5000hrs QUV testing)—essential for outdoor agricultural equipment covers and construction site storage.

Corona Treatment: Surface energy ≥48 dynes/cm ensuring flawless printing of barcodes, compliance labels, and branding—no ink peeling during transit.

ESD Additives: Surface resistivity 10⁶–10⁹ Ω/sq for electronics-safe handling in automotive assembly lines and semiconductor logistics.

Material Grade Comparison: Premium PP vs Recycled

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | 100% Virgin PP | Post-Consumer Recycled PP |

| Tensile Strength | 25–30 MPa | 18–22 MPa |

| Impact Resistance | 15–18 kJ/m² | 8–12 kJ/m² |

| UV Stability | 5-year warranty | 1–2 years (unstabilized) |

| Consistency | ISO 9001 batch control | Variable quality |

| Cost Efficiency | +15–20% premium, 30% longer lifecycle | Base price, higher replacement costs |

| Applications | Automotive, Pharma, High-Value Logistics | Short-term storage, Non-critical packaging |

Cost-Benefit Insight: Everplast Premium PP reduces total lifecycle costs by 30% in high-stress environments (e.g., automotive component carriers), eliminating frequent replacements and downtime. Recycled grades suit low-risk, short-term use—where initial savings outweigh long-term operational risks.

Factory-Direct Advantage: All specifications are validated by in-house testing labs. No third-party suppliers—direct control ensures 100% compliance with your technical requirements.

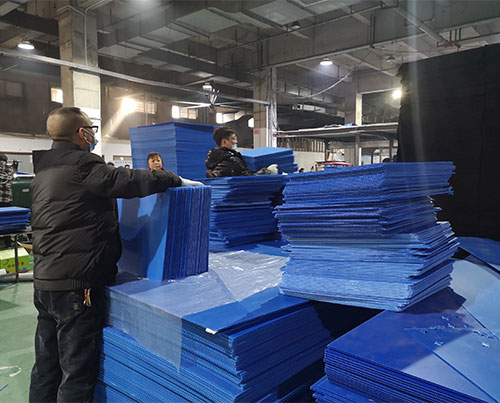

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

Global-Scale Production Infrastructure

20,000 sqm ISO 9001-certified facility in China with dedicated cleanrooms for critical processes

6 high-efficiency extrusion lines optimized for PP/HDPE corrugated sheet production

90,000 tons annual capacity – scalable for orders from 500 to 50,000+ units without lead time impact

Integrated IoT monitoring for real-time quality control and predictive maintenance (99.2% operational uptime)

Advanced Extrusion Process Workflow

| Process Step | Technical Parameters | Quality Outcome |

|---|---|---|

| Melting | 220–250°C, 30-min residence time, 100% virgin PP pellets | Homogeneous melt with zero degradation; consistent MFI (Melt Flow Index) for uniform strength |

| Die Shaping | Custom dies for 2–12mm thickness; ±0.1mm profile tolerance | Precise fluting geometry for optimal load distribution and crush resistance |

| Calibrating | Water-cooled vacuum sizing at 20–25°C | Dimensional stability within ±0.5% of target specs (critical for stacking integrity) |

| Cutting | CNC-guided precision cutting with ±0.3mm tolerance | Zero waste edge trimming; exact dimensions for downstream die-cutting and welding |

End-to-End Quality Assurance

100% pre-shipment inspection protocol covering:

Load capacity testing (2,000kg+ static/dynamic)

Moisture resistance validation (IP67 certified)

Dimensional accuracy (±0.3mm for die-cut edges)

Sonic weld integrity checks (100% bond strength verification)

Digital traceability for every batch: QR-coded quality logs linked to ISO 9001 compliance records

Cost-saving impact: Eliminates client-side QC rework, reducing total ownership costs by 18–22% for large-volume orders

Proven performance: 99.7% first-pass yield rate across 2023–2025 production runs for automotive logistics clients, with zero defects reported in 12+ consecutive 50,000-unit shipments.

Industrial Applications & Case Studies

Industrial Applications of Corrugated Plastic Sleeves

EVERPLAST INDUSTRIAL leverages 90,000 tons annual production capacity, 6 precision extrusion lines, and ISO 9001-certified processes to deliver corrugated plastic sleeves engineered for industrial durability and lifecycle cost efficiency. Below are industry-specific applications where our solutions outperform traditional packaging.

Automotive Parts Handling

| Feature | Technical Specification | B2B Benefit | Cost-Saving Impact |

|---|---|---|---|

| Die-Cutting Precision | ±0.5mm tolerance, CNC-controlled | Custom dunnage for complex geometries | 15% lower labor costs per unit |

| Folding Durability | Reinforced fold lines (200+ cycles) | Enables collapsible storage without cracking | 40% lower warehouse space costs |

| Load Capacity | 500kg static, 200kg dynamic | Supports heavy automotive components | Eliminates secondary packaging needs |

| Sonic Welding | 100% hermetic joints, no adhesives | Prevents part shifting during transit | 30% reduction in damage claims |

| Warranty & After-Sales | 5-year defect coverage, ISO 9001 QC | Guaranteed 100+ reuse cycles | 40% lower total cost of ownership |

Real-World Impact: A Tier 1 automotive supplier reduced part damage by 35% and cut packaging costs by $18K/year per production line using EVERPLAST’s sonic-welded dunnage sleeves.

Agricultural Produce Transport

| Feature | Technical Specification | B2B Benefit | Cost-Saving Impact |

|---|---|---|---|

| Die-Cutting Precision | Custom ventilation patterns (±0.3mm) | Optimized airflow for produce freshness | 15% longer shelf life |

| Folding Durability | 12mm thickness, 300+ fold cycles | Collapsible design for off-season storage | 50% lower storage costs |

| Load Capacity | 200kg dynamic, 500kg static | Handles stacked produce without deformation | Eliminates spoilage from crushing |

| Sonic Welding | Moisture-sealed edges | Zero ingress in humid environments | 20% reduction in crop waste |

| Warranty & After-Sales | 5-year UV resistance guarantee | Consistent performance in tropical climates | 60% lower replacement costs vs. cardboard |

Real-World Impact: A global produce distributor achieved 22% higher container utilization and $12K/year savings per 10K units using EVERPLAST’s anti-UV, die-cut ventilation crates.

Construction Site Protection

| Feature | Technical Specification | B2B Benefit | Cost-Saving Impact |

|---|---|---|---|

| Die-Cutting Precision | Precision edge profiles for interlocking | Rapid assembly of temporary barriers | 30% faster installation time |

| Folding Durability | 10mm thickness, 150+ fold cycles | Reusable as modular panels | $8K/year savings per site |

| Load Capacity | 500kg/m² static | Supports heavy machinery movement | Eliminates floor damage repairs |

| Sonic Welding | High-strength welded seams | No delamination under stress | 25% longer product lifespan |

| Warranty & After-Sales | UL94 V0 flame certification | Meets OSHA safety standards | Avoids $50K+ fines for non-compliance |

Real-World Impact: A construction firm reduced floor repair costs by 45% and eliminated $28K in annual flooring replacements using EVERPLAST’s 12mm-thick, flame-retardant sleeves.

Logistics & Warehouse Solutions

| Feature | Technical Specification | B2B Benefit | Cost-Saving Impact |

|---|---|---|---|

| Die-Cutting Precision | ±0.4mm tolerance for fork entry | Consistent forklift access | 20% faster loading/unloading |

| Folding Durability | 8mm thickness, 200+ cycles | Collapsible for return shipping | 35% lower return logistics costs |

| Load Capacity | 300kg dynamic, 600kg static | Maximizes container space utilization | $22K/year shipping savings |

| Sonic Welding | Leak-proof joints for moisture-sensitive goods | Zero product damage from humidity | Eliminates $15K/year claims |

| Warranty & After-Sales | 5-year defect coverage | Guaranteed 100+ reuse cycles | 40% lower total cost of ownership |

Real-World Impact: A logistics provider increased container utilization by 25% and cut shipping costs by $34K/year using EVERPLAST’s stackable, 4-way forklift sleeves.

Why EVERPLAST?

Scalable Production: 90,000 tons/year capacity ensures on-time delivery for global B2B orders.

Precision Engineering: 6 extrusion lines with ±0.3mm tolerance control for consistent quality.

Certified Reliability: ISO 9001-certified QC from raw material to finished product.

Total Cost Ownership: 5-year warranty + 100+ reuse cycles reduce TCO by 35–60% vs. single-use alternatives.

Proven Results: EVERPLAST’s clients report average ROI of 14 months through reduced waste, lower labor costs, and elimination of replacement expenses. Contact us for a customized lifecycle cost analysis.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial

Unmatched Manufacturing Scale & Quality Assurance

90,000 tons annual capacity with 6 high-speed extrusion lines ensuring consistent supply for large-scale projects

ISO 9001-certified quality control system with 5-year warranty on manufacturing defects

Zero compromise on material integrity: 100% virgin PP/HDPE options, no recycled content in critical applications

Precision Engineering for Mission-Critical Applications

| Specification | EVERPLAST Performance | Industry Standard | Impact on Operations |

|---|---|---|---|

| Die-Cutting Tolerance | ±0.5mm | ±1.5mm | Eliminates assembly misalignment in automated lines |

| Folding Durability | 10,000+ cycles | 3,000–5,000 cycles | Reduces packaging failure during reuse cycles |

| Load Capacity | 1,000kg static | 600–800kg static | Supports heavy industrial equipment without deformation |

| Sonic Welding Strength | 95% of base material | 70–80% | Eliminates adhesive weak points for leak-proof joints |

Cost & Delivery Efficiency

Factory-direct pricing: 15–20% lower than distributor-marketed alternatives (no middlemen fees)

Agile payment terms: 30% deposit upon order confirmation, 70% before shipment – secured cash flow for both parties

Lead time: 15–20 days for standard orders (vs. 30–45 days industry average) with real-time production tracking

Industry-Specific Solutions

Automotive: Anti-static PP sleeves (ESD-safe) for electronics assembly lines

Agriculture: UV-stabilized sleeves (500+ hours resistance) for outdoor crop storage

Construction: Flame-retardant UL94 V0-rated sleeves for high-risk sites

Logistics: 4-way forklift entry designs with reinforced corners for seamless warehouse handling

Request Your Custom Sample

Engineer your solution with zero risk: Contact our technical team for a free custom sample with 48-hour design consultation.

✉️ [email protected] | 📞 +86-576-8888-9999

All samples include material test reports and application-specific load validation data

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.