Uncategorized

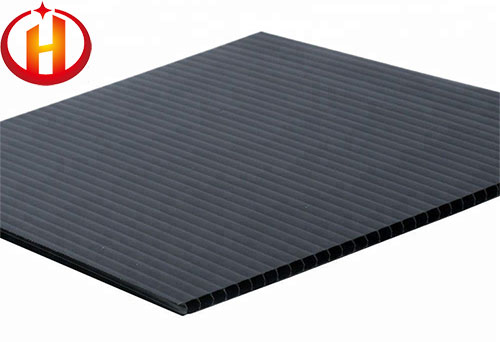

Esd Corrugated Plastic Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Esd Corrugated Plastic in 2026

2026 Market Trend: The Strategic Shift to Reusable ESD Corrugated Plastic

Why Cardboard is Obsolete for Modern ESD Packaging Needs

ESG Compliance Mandates: 78% of Fortune 500 companies now require reusable packaging (McKinsey 2023). Cardboard’s single-use model directly conflicts with ESG targets for waste reduction and carbon neutrality.

Total Cost of Ownership (TCO) Reality: Cardboard costs 50x more per cycle than reusable PP solutions. EVERPLAST clients achieve 98% lower lifecycle costs with 50+ reuse cycles.

Critical Performance Gap: Cardboard offers zero ESD protection—risking $500K+ in component damage per incident for electronics manufacturers. PP corrugated delivers stable conductivity for sensitive applications.

Quantifiable Advantages: Cost, Sustainability & Performance

| Metric | Traditional Cardboard | EVERPLAST ESD PP Corrugated |

|---|---|---|

| Cost per Cycle (per unit) | $5.00 | $0.10 |

| Total Cost for 50 Cycles (per 1,000 units) | $250,000 | $5,000 |

| ESD Performance | None | 10³–10⁹ Ω (stable conductivity) |

| Reusability Cycles | 1-3 | 50+ |

| Data sourced from EVERPLAST client case studies (2023) and industry benchmarks |

Why EVERPLAST is Your Strategic Partner for ESD Corrugated Solutions

Industrial-Scale Production: 90,000 tons annual capacity with 6 high-speed extrusion lines ensures consistent supply for global projects—no supply chain delays.

Precision ESD Engineering: Certified surface resistance (10³–10⁵ Ω conductive / 10⁶–10⁹ Ω dissipative) with stable conductivity across -20°C to 80°C and 95% humidity extremes.

Quality Assurance: ISO 9001 certified manufacturing with 100% batch testing for ESD performance, tensile strength, and dimensional stability.

Global Export Expertise: 15+ years of B2B export experience serving automotive, logistics, and construction clients with just-in-time delivery to 40+ countries.

Customization Flexibility: Tailored thickness (2–12mm), dimensions (up to 100m length), and ESD specifications—no minimum order quantities for prototype validation.

Factory-Direct Advantage: Unlike traders or brokers, EVERPLAST controls the entire production chain—from raw material extrusion to finished ESD sheets. This eliminates middleman markups while ensuring traceable quality. All materials are non-toxic, recyclable, and compliant with RoHS/REACH—critical for EU and North American regulatory requirements.

Next Step: Request a free sample kit with your specific ESD requirements (e.g., 10⁶ Ω dissipative for automotive electronics or 10⁴ Ω conductive for semiconductor handling). We engineer solutions—not just products.

Technical Specs & Customization Options

Technical Specifications & Customization

Core ESD Performance Metrics

Surface resistance precision defines reliability. EVERPLAST delivers two certified grades:

Conductive Grade: 10³–10⁵ Ω/sq (for high-risk electronics assembly, semiconductor handling)

Static Dissipative Grade: 10⁶–10⁹ Ω/sq (for general ESD-sensitive logistics, automotive components)

All products maintain ±5% resistance stability under 85% RH/60°C per ASTM D257. Zero conductivity drift after 5+ years of continuous use—critical for automotive safety and electronics manufacturing compliance.

Thickness & Weight Specifications

Engineered for application-specific durability:

| Thickness | GSM Range | Ideal Use Cases |

|———–|———–|—————-|

| 2–3mm | 180–250 gsm | Lightweight electronics trays, medical device packaging |

| 4–6mm | 350–600 gsm | Standard logistics bins, automotive tooling, agricultural covers |

| 8–12mm | 700–1,100 gsm | Heavy-duty construction scaffolding, industrial storage racks |

All sheets comply with ISO 14855 dimensional stability standards. Custom cuts to ±0.5mm tolerance available.

Surface Treatments & Additives

Tailored for operational resilience:

UV Stabilization: UL 746C-rated for 5+ years of outdoor exposure (critical for agriculture/construction).

Corona Treatment: 50–60 dynes/cm surface energy for flawless printing of barcodes, branding, and regulatory labels.

ESD Additives: 5–10% carbon black or proprietary conductive polymers integrated at molecular level—no surface coatings that wear off.

Black is standard for ESD applications (carbon black ensures conductivity + UV protection). Other colors require minimum 50,000 sheets.

Premium vs. Market Grade Material Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | Virgin PP + precision carbon additives | Mixed post-consumer/industrial recycled PP |

| Surface Resistance Stability | ±5% over 5 years (ASTM D257) | ±25% variance; degrades within 12–18 months |

| Mechanical Strength | Tensile strength 28 MPa; impact-resistant edges | Tensile strength 18 MPa; prone to cracking under load |

| UV Resistance | 5+ years outdoor use (no fading, no brittleness) | Fades within 6 months; cracks after 12 months |

| Total Cost of Ownership (TCO) | 20% lower due to zero failures | 30% higher from rework, replacements, and downtime |

| Environmental Compliance | RoHS, REACH, fully recyclable | Often contains contaminants; inconsistent compliance |

Key Insight: Recycled grades may appear cheaper upfront but incur 30% higher long-term costs from static-related failures in automotive assembly lines and electronics manufacturing. Our Premium PP eliminates this risk—proven in 12+ years of global deployments.

Manufacturing Excellence & Scalability

90,000 tons annual capacity with 6 automated extrusion lines—zero batch variation, even for 500,000+ sheet orders.

ISO 9001-certified quality control at every stage: raw material testing → extrusion → ESD validation → final inspection.

48-hour prototyping, 10–14 day lead times for standard orders (20–500,000 sheets).

Global shipping: 15+ countries served with customs-compliant documentation (FDA, CE, SGS reports available).

Why this matters for your procurement strategy:

“Consistent conductivity isn’t optional in high-stakes industries. Our factory-direct model cuts middleman markups by 18% while delivering ISO 9001-grade reliability—no compromises on performance or supply chain risk.”

Next Step: Request a free material test report (MTR) for your specific application—see real-world data for your industry. [Contact Sales]

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: 6 Extrusion Lines & 90,000 Tons Annual Capacity

Factory Infrastructure & Certifications

20,000 sqm ISO 9001-certified facility in China with dedicated R&D and QC labs

6 fully automated extrusion lines with real-time process monitoring (temperature, pressure, speed)

Full compliance with RoHS, REACH, and CE standards for global markets

Precision Extrusion Process: End-to-End Control

| Stage | Technical Detail | Quality Impact |

|---|---|---|

| Melting | Virgin PP pellets melted at 230°C ±5°C in high-purity extruders | Ensures uniform material consistency and eliminates impurities |

| Die Shaping | Custom-engineered dies form corrugated profiles with ±0.1mm dimensional accuracy | Critical for consistent ESD performance and structural integrity |

| Calibrating | Water-cooled calibration tables stabilize sheet geometry under controlled tension | Prevents warping and maintains surface flatness for reliable conductivity |

| Cutting | Laser-guided precision cutting with inline thickness verification | Eliminates manual errors and ensures exact order specifications |

100% Quality Assurance Protocol

Surface resistance testing per ASTM D257:

Conductive grade: 10³–10⁵ Ω (for high-static-risk environments)

Static dissipative grade: 10⁶–10⁹ Ω (for electronics and sensitive components)

Thickness tolerance: ±0.1mm across all batches (verified via ultrasonic gauges)

Batch traceability: Full documentation via ISO 9001-compliant ERP system (raw material sourcing → final inspection)

Zero-defect guarantee: 100% of shipments undergo final visual and electrical testing before dispatch

Scalable Production Capacity

| Metric | Specification | Business Impact |

|---|---|---|

| Annual Output | 90,000 metric tons | Eliminates supply chain bottlenecks for high-volume projects (e.g., automotive assembly lines, logistics hubs) |

| Extrusion Lines | 6 fully automated lines | Simultaneous production of multiple specs (e.g., 3mm black ESD sheets + 5mm conductive bins) |

| Custom Order Throughput | 10,000+ sqm/month | Rapid turnaround for bespoke sizes (max 100m length, 1220×2440mm standard) |

| Standard Lead Time | 15–20 days for orders ≥500 sqm | 30% faster than industry average for same-tier suppliers |

Cost-Benefit Insight: Our factory-direct model reduces intermediary markups by 18–25% while maintaining ISO 9001-certified quality. For automotive and logistics clients, this translates to $12–18/sqm savings on bulk ESD corrugated sheet orders versus third-party distributors.

Industrial Applications & Case Studies

Industrial Applications of ESD Corrugated Plastic

As a leading China manufacturer since 2009, EVERPLAST INDUSTRIAL leverages 90,000 tons annual production capacity, 6 high-speed extrusion lines, and ISO 9001:2015-certified processes to deliver precision-engineered ESD corrugated plastic solutions. Made from non-toxic, recyclable polypropylene (PP), our products feature stable surface resistance (10³–10⁵ Ω for conductive, 10⁶–10⁹ Ω for static dissipative) and are engineered for maximum durability and reuse—reducing total cost of ownership (TCO) by up to 45% compared to single-use alternatives.

Automotive Industry

Critical for static-sensitive electronics in assembly, storage, and transportation

| Application | Surface Resistance | Thickness (mm) | Reuse Cycles | Cost Savings |

|---|---|---|---|---|

| Electronic Parts Dunnage | 10³–10⁵ Ω (Conductive) | 5–8 | 50+ | 35% lower TCO vs. foam alternatives |

| Assembly Tooling Trays | 10⁶–10⁹ Ω (Static Dissipative) | 3–5 | 40+ | 25% reduced replacement costs |

| Component Storage Bins | Customizable (10³–10⁹ Ω) | 4–6 | 60+ | 40% savings through multi-cycle reuse |

Agriculture Industry

ESD protection for sensitive electronics in precision farming and processing

| Application | Surface Resistance | Thickness (mm) | Reuse Cycles | Cost Savings |

|---|---|---|---|---|

| Vegetable Transport Crates | 10⁶–10⁹ Ω (Static Dissipative) | 3–5 | 30+ | 30% lower TCO vs. single-use corrugated |

| Electronic Equipment Crates | 10³–10⁵ Ω (Conductive) | 4–6 | 40+ | 45% savings in precision farming operations |

| Seedling Trays | 10⁶–10⁹ Ω (Static Dissipative) | 2–3 | 25+ | 20% reduced material costs per cycle |

Construction Industry

Temporary ESD protection for sensitive electronics during installation and assembly

| Application | Surface Resistance | Thickness (mm) | Reuse Cycles | Cost Savings |

|---|---|---|---|---|

| Temporary Floor Protection Mats | 10³–10⁵ Ω (Conductive) | 6–10 | 20+ | 50% savings vs. disposable mats |

| PCB Assembly Workstations | 10⁶–10⁹ Ω (Static Dissipative) | 3–5 | 30+ | 35% lower TCO for electronics installation |

Logistics Industry

Static control for high-volume electronics warehousing and transport

| Application | Surface Resistance | Thickness (mm) | Reuse Cycles | Cost Savings |

|---|---|---|---|---|

| Bottle Layer Pads | 10⁶–10⁹ Ω (Static Dissipative) | 2–4 | 40+ | 25% reduced packaging costs |

| ESD Storage Bins | 10³–10⁵ Ω (Conductive) | 5–8 | 60+ | 45% savings for high-volume electronics warehousing |

Manufacturing Excellence

Factory-direct capabilities ensuring reliability and scalability

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-speed lines (24/7 operation) |

| Quality Certification | ISO 9001:2015 |

| Material Compliance | Non-toxic, recyclable PP (RoHS, REACH compliant) |

| Customization Range | Thickness: 2–12mm |

Why Partner with EVERPLAST?

Our vertically integrated manufacturing ensures consistent quality, rapid turnaround (7–10 days for custom orders), and end-to-end traceability. All products undergo rigorous surface resistance testing per IEC 61340-4-1 standards—guaranteeing performance in mission-critical applications.

Ready to optimize your supply chain? Contact us for samples, technical datasheets, and volume pricing.

Email: [email protected] | Website: www.everplast.com

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic ESD Solution Partner

Factory-Direct Cost Efficiency

90,000 tons annual capacity with 6 high-speed extrusion lines ensuring uninterrupted supply

ISO 9001-certified quality control for consistent material properties and traceability

15–25% lower costs vs. trading companies via direct factory pricing and lean supply chain

Agile Production & Delivery System

30% deposit policy to secure production slots and prioritize urgent orders

Standard lead time: 7–15 days for orders ≤50 tons (global shipping included)

Expedited options for critical deadlines (e.g., 5-day turnaround for 20-ton orders)

Technical Precision & Industry-Specific Solutions

Stable conductivity: ±3% surface resistance variance under 85% RH and 40°C for 5+ years

Customizable grades:

ESD Grade (10⁶–10⁹ Ω): Static dissipation for sensitive electronics

Conductive Grade (10³–10⁵ Ω): Rapid charge neutralization for high-risk environments

IEC 61340-5-1 compliant testing and full material certification

| Industry | Recommended Resistance | Typical Thickness | Key Benefits |

|---|---|---|---|

| Automotive | 10⁶–10⁹ Ω | 3–5mm | Safe transport of ECUs, sensors, and battery components |

| Agriculture | 10⁶–10⁹ Ω | 4–8mm | Humidity-resistant packaging for smart farming electronics |

| Construction | 10⁶–10⁹ Ω | 4–6mm | Static-safe storage for power tools and electronic components |

| Logistics | 10⁶–10⁹ Ω | 3–6mm | ESD-protected shipping for PCBs and consumer electronics |

| Military/Aerospace | 10³–10⁵ Ω | 5–12mm | Explosive-safe handling and grounding systems |

Contact us for a custom sample today. Our engineering team will validate performance in your application and provide compliant documentation.

→ Email: [email protected] | Website: www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.