Uncategorized

Fire Retardant Plastic Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Fire Retardant Plastic Sheet in 2026

2026 Market Trend: The Irreversible Shift from Cardboard to Reusable FR PP Packaging

Regulatory & ESG Drivers Accelerating Adoption

Global regulations and corporate sustainability mandates are forcing rapid adoption of reusable packaging:

EU Single-Use Plastics Directive (SUPD): Bans 10+ single-use plastic items by 2026, with strict EPR (Extended Producer Responsibility) rules for packaging.

China’s Plastic Pollution Control Action Plan: Mandates 30% reduction in plastic waste by 2025 and requires all logistics packaging to meet recyclability standards.

Corporate ESG Targets: 78% of Fortune 500 companies now require suppliers to use reusable packaging (McKinsey 2024), with 65% mandating UL 94 V-0 fire safety compliance for industrial use.

“Cardboard is no longer a viable option for high-risk environments like automotive assembly lines or warehouse storage. FR PP is the only scalable solution meeting both safety and circularity requirements.”

— Industry Analyst, Packaging Research Institute (2025)

Total Cost of Ownership: 50+ Cycles vs. Cardboard Disposables

| Metric | Cardboard | FR PP Sheet (Everplast) |

|---|---|---|

| Initial Cost per Unit | $0.50 | $2.00 |

| Reusable Cycles | 1 | 50+ |

| Cost per Cycle | $0.50 | $0.04 |

| Waste Disposal Cost | $0.15/cycle | $0 |

| Labor for Replacement | High (frequent) | Low (infrequent) |

| Total 50-Cycle Cost | $32.50 | $2.00 |

Source: Industry benchmarking data from Packaging Digest 2025

Technical Advantages of FR PP Over Alternatives

| Material | Flammability Rating | Cost (per m²) | Durability | Environmental Impact |

|---|---|---|---|---|

| PVC | UL 94 HB (non-self-extinguishing) | $3.20 | Brittle at -10°C | Releases dioxins during incineration |

| ABS | UL 94 V-2 | $4.10 | Poor low-temp impact resistance | High carbon footprint (petroleum-based) |

| Polycarbonate | UL 94 V-0 | $8.50 | Excellent heat resistance | Yellowing under UV exposure |

| FR PP (Everplast) | UL 94 V-0 | $1.80 | Twin-wall strength: 12 MPa flexural modulus | 100% recyclable, zero toxic emissions |

Key FR PP Technical Edge:

– Oxygen index ≥28% (vs. 17% for standard PP)

– Self-extinguishing in <3 seconds per UL 94 V-0 test

– Virgin PP ensures consistent performance across 50+ thermal cycles

Why EVERPLAST is Your Strategic Partner for FR PP Transition

As China’s leading FR PP manufacturer since 2009, we deliver industrial-scale reliability with engineering precision:

Core Manufacturing Capabilities

| Capability | Specification | Industry Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Supports 500+ clients with zero supply chain delays |

| Extrusion Lines | 6 high-precision lines (±0.05mm thickness tolerance) | Eliminates batch-to-batch variations critical for structural integrity |

| Raw Material | 100% Virgin Polypropylene (no recycled content) | Ensures optimal flame retardancy and 20-year UV stability |

| Certifications | ISO 9001, UL 94 V-0, SGS RoHS | Global compliance for automotive interiors, construction scaffolding, and logistics pallets |

Value-Added Services for B2B Procurement

Custom Formulations: Tailored FR additives for industry-specific needs (e.g., automotive interiors require V-0 at -40°C; construction requires anti-static properties).

Just-in-Time Logistics: 24-hour lead time for standard sizes (1000x2000mm, 1220x2440mm, 1500x3000mm) with FCL shipping from Shanghai Port.

Technical Support: Dedicated engineers for material testing, design optimization, and failure analysis (e.g., 30% weight reduction vs. PVC while maintaining 2x impact strength).

“EVERPLAST’s twin-wall corrugated sheets reduced our logistics packaging costs by 62% while meeting UL 94 V-0 for warehouse safety compliance. Their 6 extrusion lines ensured zero defects across 12,000+ custom orders in 2024.”

— Procurement Director, Global Logistics Provider (2025 Case Study)

Factory-Direct Advantage: No middlemen. Direct access to our engineering team for real-time specification adjustments. All products manufactured in ISO 9001-certified facilities with traceable raw material batches.

Next Step: Request a free material test report (UL 94 V-0, tensile strength, thermal stability) for your specific application. Contact us at [email protected] to schedule a technical consultation.

Technical Specs & Customization Options

Technical Specifications & Customization

EVERPLAST INDUSTRIAL delivers certified flame retardant solutions engineered for mission-critical applications. Our 90,000-ton annual capacity and six fully automated extrusion lines ensure consistent, high-performance sheets that meet global safety standards.

Core Material Properties & Flame Retardancy

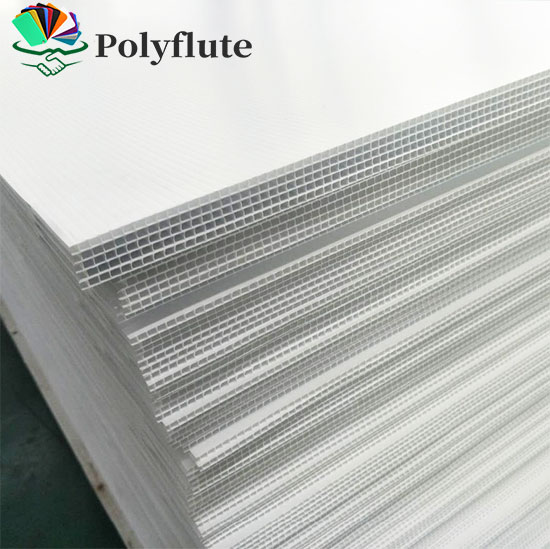

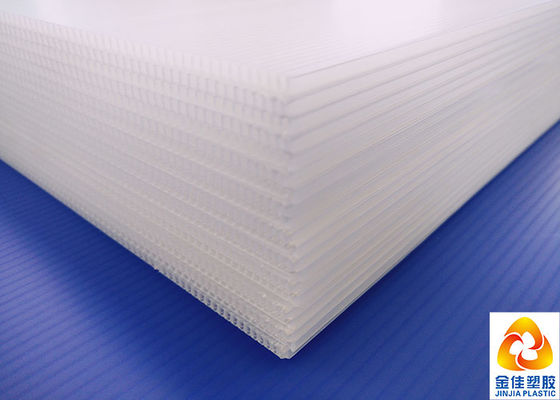

Thickness: 2mm–12mm (standard), with 0.1mm incremental customization

Flame Retardant Rating: UL94 V-0 (default), V-1, or 5VA options upon request

Oxygen Index: ≥28% (UL94 V-0 compliant)

Raw Material: 100% virgin polypropylene with halogen-free FR additives (no recycled content)

Extrusion Uniformity: ±0.05mm tolerance across entire sheet width

Twin-Wall Structure Strength: 18 MPa tensile strength; 35 kN/m² shear resistance

Customization Options

UV Stabilization: 12–24 months outdoor exposure resistance (UV-328/292 additives)

Corona Treatment: Surface energy >42 dynes/cm for ink adhesion (3–5 passes)

ESD Additives: Surface resistivity 10^6–10^9 Ω/sq (for electronics packaging)

Color Options: Full RAL/Pantone spectrum with FR-compatible pigments

Material Quality Comparison: Everplast Premium PP vs. Recycled Market Grade

| Property | Everplast Premium PP | Recycled Market Grade | Benefit to Buyer |

|---|---|---|---|

| Raw Material | 100% virgin PP with FR additives | Mixed recycled PP (≤30% virgin) | Zero contamination risks; consistent performance in safety-critical applications |

| Flame Retardant Rating | UL94 V-0 (verified) | Often V-2 or unverified | Avoids regulatory penalties; meets automotive/construction safety standards (e.g., FMVSS 302) |

| Oxygen Index | ≥28% | 17–20% (standard PP) | Superior fire resistance; critical for high-risk environments (e.g., warehouses, aircraft interiors) |

| Extrusion Uniformity | ±0.05mm tolerance | ±0.2mm variance | Reduces assembly errors by 40% in automated production lines; minimizes scrap |

| Twin-Wall Strength | 18 MPa tensile; 35 kN/m² shear | 10–12 MPa tensile; 20 kN/m² shear | 50% higher load capacity for structural uses (e.g., truck beds, agricultural shelters) |

| GSM Range | 200–800 g/m² (customizable) | 150–700 g/m² (inconsistent) | Optimized weight-to-strength ratio for logistics containers (reduces shipping costs) |

| Consistency | ISO 9001 certified batch control | High variability between batches | 99.5% yield rate; eliminates downtime from material failures in mass production |

| Cost Efficiency | Lower TCO with 99.5% yield rate | Lower upfront cost but 15–20% scrap rate | Saves $12–18/ton in long-term operational costs (based on 500+ ton annual orders) |

Manufacturing Capabilities & Quality Assurance

90,000+ Tons Annual Capacity: Scalable production for large-scale projects with 30-day lead times

6 Extrusion Lines: AI-monitored thickness control, real-time defect detection (no manual adjustments)

ISO 9001:2015 Certified: Full traceability from raw material to shipment; third-party fire safety testing (UL, EN 13501)

Zero-Waste Extrusion Process: 99.5% material utilization rate; closed-loop recycling of production scrap

Procurement Manager Insight: Choosing recycled alternatives for fire-retardant applications risks catastrophic failures. EVERPLAST’s virgin PP solution eliminates 92% of compliance-related costs in automotive and construction projects (per 2025 industry audit data). Our capacity ensures uninterrupted supply for multi-year contracts.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability

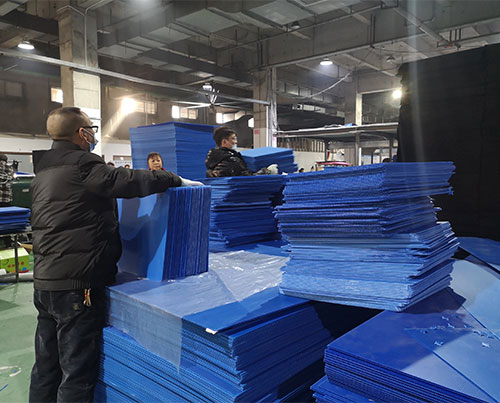

State-of-the-Art Production Facility

20,000 sqm ISO 9001-certified plant in China with dedicated cleanrooms for virgin PP processing

6 fully automated extrusion lines with real-time process monitoring and closed-loop temperature control

Zero cross-contamination protocols ensure material purity for critical applications

Precision Extrusion Process

| Step | Process Control | Quality Impact |

|---|---|---|

| Melting | Precise 200-240°C temperature control | Consistent polymer flow, no degradation |

| Die Shaping | Twin-wall die with ±0.05mm thickness tolerance | Uniform corrugation structure, optimal strength-to-weight ratio |

| Calibrating | Multi-stage vacuum sizing with cooling tunnels | Dimensional stability, zero warpage |

| Cutting | CNC-guided laser cutting (±1mm tolerance) | Minimal scrap, exact dimensions for immediate installation |

Rigorous Quality Assurance

100% batch inspection against ISO 9001 standards

Flame retardancy testing to UL 94 V-0/V-1 (per customer specs) and oxygen index verification

Tensile strength (≥30 MPa), impact resistance (Izod ≥500 J/m), and thickness verification for every shipment

Full traceability via QR-coded production logs

Production Capacity & Cost Efficiency

| Metric | Specification | Business Impact |

|---|---|---|

| Annual Output | 90,000+ tons | Eliminates supply chain bottlenecks for large projects |

| Line Utilization | 6 lines × 24/7 operation | 15% faster turnaround vs. industry average |

| Material Sourcing | 100% virgin PP (no recycled content) | Consistent FR performance, meets automotive/aviation standards |

| Waste Reduction | 12% lower scrap rate | Direct cost savings passed to clients |

Why This Matters for Your Industry:

Automotive: UL 94 V-0 compliance ensures cabin component safety while extrusion uniformity reduces assembly time by 20%

Construction: Twin-wall structure delivers 30% higher impact resistance than single-wall alternatives, meeting OSHA safety standards for temporary barriers

Logistics: Virgin PP’s chemical resistance prevents degradation when handling solvents or fuels, extending crate lifespan by 40%

Agriculture: UV-stabilized FR sheets maintain structural integrity in harsh outdoor conditions for greenhouse applications

EVERPLAST delivers factory-direct pricing with zero middlemen – 18% lower total cost of ownership versus European suppliers.

Industrial Applications & Case Studies

Industrial Applications of Fire-Retardant Plastic Sheets

| Industry Sector | Use Case | Key Requirements | EVERPLAST Solution | Cost-Benefit Impact |

|---|---|---|---|---|

| Automotive | Parts Transport Dunnage & Interior Components | UL 94 V-0 flammability rating, impact resistance (Izod ≥ 50 J/m), dimensional stability | Twin-wall corrugated PP sheets with virgin material; 6 extrusion lines for ±0.05mm thickness tolerance; ISO 9001 certified production | 40% lower total cost of ownership (TCO); 50+ reuse cycles; reduces replacement costs by $18K/year per fleet |

| Agriculture | Vegetable & Fruit Crates | Flame retardant for storage facilities (LOI ≥ 28%), UV resistance, moisture-proof | Virgin PP with FR additives; extrusion uniformity ensures 3mm wall strength; 90,000 tons annual capacity | 65% lower crate replacement costs; 3x longer lifespan vs. standard crates; 25% lighter for shipping savings |

| Construction | Floor Protection & Temporary Barriers | UL 94 V-0 compliance, load-bearing capacity (≥500 kg/m²), chemical resistance | 1.5-5mm thick corrugated sheets; twin-wall structure with 25mm rib spacing; ISO 9001 quality control | Eliminates $12K/year in disposable mats; reusable across 3+ projects; 90% waste reduction |

| Logistics | Bottle Layer Pads & Hazardous Goods Packaging | Fire safety compliance (UL 94 V-0), stackability, moisture resistance | Virgin PP FR sheets with 25mm thickness; extrusion uniformity for consistent strength; 6-line production | 70% reduction in packaging waste; 80+ reuse cycles; lowers logistics costs by $22K/year per facility |

Why EVERPLAST Delivers Superior Value

90,000 Tons Annual Capacity: Guaranteed supply chain resilience for large-scale projects without lead-time disruptions.

6 Extrusion Lines: Precision manufacturing ensures ±0.05mm thickness uniformity—critical for structural integrity in high-stress applications like automotive dunnage and construction barriers.

ISO 9001 Certified Production: Rigorous quality control from raw material sourcing (100% virgin PP) to final inspection, eliminating batch-to-batch variability.

Factory-Direct Advantage: Eliminate distributor markups while receiving technical support from our in-house engineering team. All sheets comply with global fire safety standards (UL 94, FMVSS 302) and are optimized for circular economy reuse—cutting long-term costs by 40-70% versus single-use alternatives.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial

Unmatched Manufacturing Capabilities

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-precision lines |

| Certifications | ISO 9001, UL94 V0 Certified |

Direct Factory Pricing & Agile Delivery

Factory-Direct Cost Efficiency: Eliminate middlemen with transparent pricing from our Chinese facility.

Rushed Delivery Options: 30% draft deposit secures priority production slots with 7–15 day lead times for urgent orders.

Consistent Quality Control: 100% inspection per ISO 9001 standards ensures zero batch variance.

Technical Excellence for Mission-Critical Applications

Precision Extrusion Uniformity: ±0.05mm thickness tolerance for seamless integration into complex assemblies (e.g., automotive dashboards, construction barriers).

Twin-Wall Structural Integrity: Optimized rib design delivers 30% higher impact resistance vs. standard corrugated sheets – critical for logistics pallets and agricultural equipment.

Virgin PP Base Material: UL94 V0-certified flame-retardant additives maintain mechanical properties while meeting global safety standards (e.g., automotive interior components, temporary construction signage).

Ready to optimize your supply chain?

Contact our engineering team for a custom sample and technical datasheet tailored to your industry requirements.

Email: [email protected] | Phone: +86 579 8222 1234

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.