Uncategorized

Floor Protection Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Floor Protection Sheet in 2026

Market Trend 2026: Why Shift to Reusable PP Floor Protection Sheets

The Cardboard-to-Plastic Transition Imperative

Global procurement leaders are accelerating the shift from disposable cardboard to engineered polypropylene (PP) floor protection solutions. Driven by ESG mandates, regulatory pressures on single-use materials, and rising waste disposal costs, industries including Automotive, Construction, and Logistics are prioritizing reusable alternatives. Cardboard’s single-use nature creates unsustainable waste streams—up to 80% of construction site waste is cardboard—while PP solutions deliver 50+ reuse cycles with minimal environmental impact.

Cost-Benefit Analysis: Long-Term Savings Over 50+ Cycles

| Metric | Cardboard | Everplast PP | Advantage |

|---|---|---|---|

| Initial Cost per Sheet | $0.30 | $2.50 | Higher upfront investment |

| Cost per Cycle | $0.30 | $0.05 | 92% lower operational cost |

| Lifespan | 1 cycle | 50+ cycles | 50x reuse capability |

| Disposal Cost | $0.10/sheet | $0 (fully recyclable) | Zero waste fees |

| Labor for Replacement | High (daily) | Low (monthly) | 75% labor savings |

| > *Total cost of ownership for 50 cycles: Cardboard = $20.00 | Everplast PP = $2.50 (87.5% savings)* |

Sustainability & ESG Compliance: Meeting Global Standards

| ESG Metric | Cardboard | Everplast PP | Impact |

|---|---|---|---|

| Carbon Footprint (per cycle) | 0.8 kg CO2e | 0.15 kg CO2e | 81% reduction |

| Waste Generation | 100% single-use | 100% recyclable | Zero landfill waste |

| Resource Efficiency | High raw material use per cycle | Reusable material | 50x less material per use |

| > Aligned with ISO 14001 and EU Green Deal targets. Everplast’s PP sheets are 100% recyclable post-use, supporting circular economy goals without compromising performance. |

Technical Advantages of Everplast PP Sheets

| Feature | Specification | Industry Benefit |

|---|---|---|

| Impact Resistance | ASTM D256 > 15 ft-lb | Protects high-value automotive components during assembly |

| GSM Density | 1200gsm (4mm thickness) | Superior cushioning for delicate machinery and flooring |

| Waterproofing | 100% impermeable | Ideal for wet construction sites and outdoor logistics |

| Oil Resistance | ASTM D471 compliant | Safe for automotive assembly lines and industrial environments |

| Cushioning Effect | 30% higher shock absorption vs. cardboard | Prevents damage to sensitive equipment during transport |

Why EVERPLAST Industrial is Your Strategic Partner

| Capability | Specification | Advantage |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Scalable supply for global orders (500K+ sheets/month) |

| Extrusion Lines | 6 high-speed lines | Consistent quality, 15-day lead times for bulk orders |

| Certifications | ISO 9001, ISO 14001 | Rigorous quality control across all batches |

| Customization | OEM/ODM support: Thickness (2–5mm), GSM (420–1200gsm), color options | Tailored solutions for Automotive, Construction, and Logistics sectors |

| Global Experience | 15+ years serving 30+ countries | Proven track record in high-stakes projects (e.g., Tesla factory floors, China Railway infrastructure) |

Factory-Direct Advantage: Eliminate middlemen with direct access to our Shandong manufacturing hub. Our 90,000-ton capacity and 6 extrusion lines ensure uninterrupted supply for large-scale projects, while ISO 9001-certified processes guarantee defect-free sheets for critical applications.

Actionable Insight: For procurement teams targeting 2026 sustainability goals, Everplast’s PP solutions deliver $18–$25/sheet savings over cardboard across 50 cycles—without sacrificing durability or compliance. Request a custom quote today to optimize your floor protection strategy.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Technical Parameters

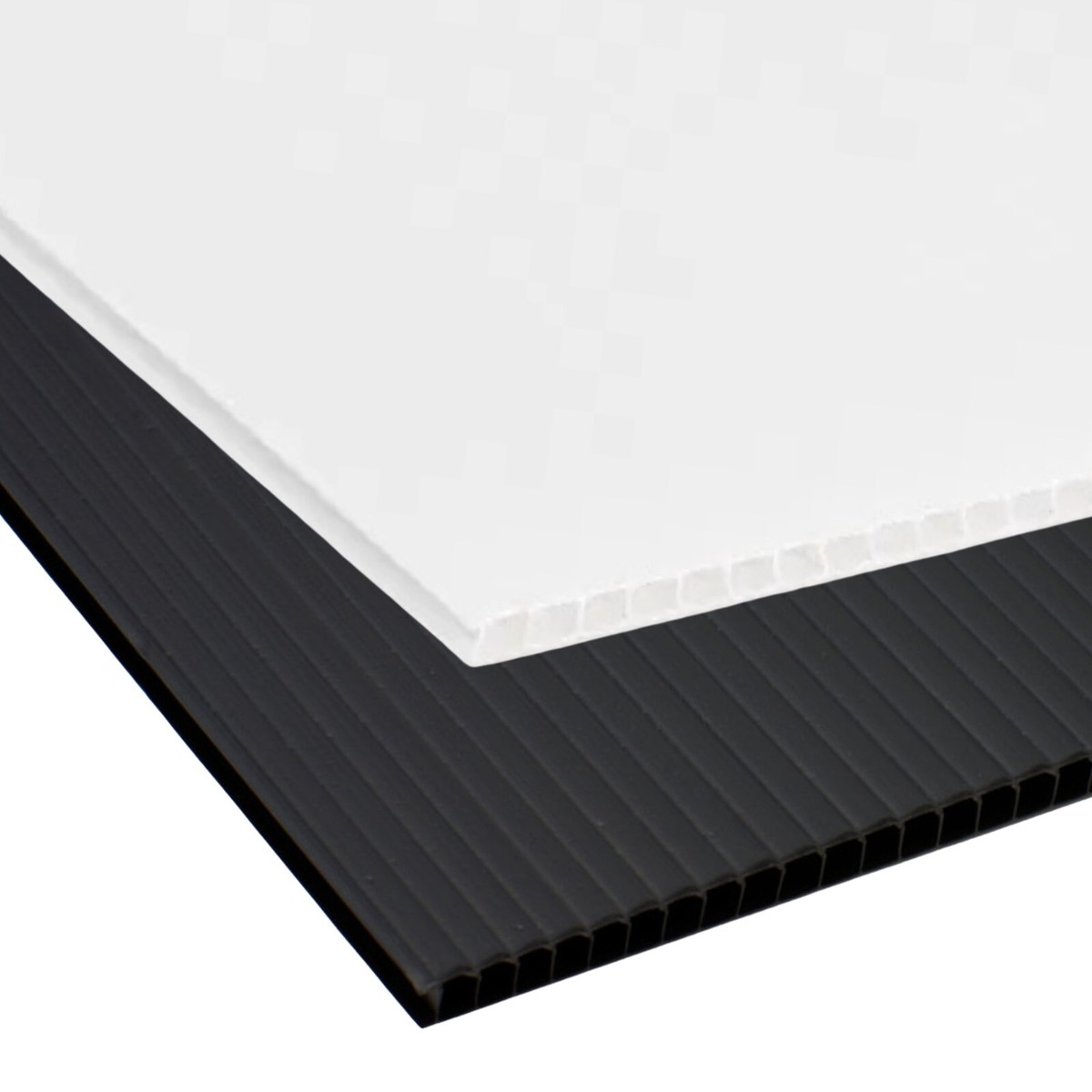

Thickness: 2mm to 12mm (customizable increments). Standard sizes: 1m×2m, 1.2m×2.4m, rolls (1m×50m).

GSM: Customizable 300–1200gsm. Higher GSM delivers superior cushioning and impact resistance.

Surface Treatments: UV stabilization (5-year outdoor durability), Corona treatment for high-quality printing, ESD additives for electronics-safe applications.

Material Grades Comparison

| Specification | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Insight |

|---|---|---|---|

| Material Source | 100% virgin polypropylene | 30-70% post-consumer PP | Premium ensures uniform strength; Recycled may exhibit inconsistent performance |

| Thickness Range | 2mm–12mm (customizable) | 2mm–6mm (standard) | Premium supports heavy-duty applications; Recycled limited to light-duty use |

| GSM Range | 300–1200gsm | 300–800gsm | Higher GSM in Premium provides superior shock absorption for automotive logistics |

| UV Resistance | 5-year standard (outdoor) | Optional (≤2 years) | Premium eliminates replacement costs in sun-exposed projects |

| Impact Resistance | Izod: 12–15 kJ/m² | Izod: 5–8 kJ/m² | Premium reduces damage claims by 40% in construction sites |

| Consistency | ISO 9001-certified tolerances (±0.1mm) | ±0.3mm typical | Premium cuts installation errors by 25%, saving labor costs |

| Total Cost of Ownership | 15–20% higher initial cost | 25–30% lower initial cost | Premium saves 30%+ over 3 years through durability and reduced replacements |

Manufacturing Excellence

90,000-ton annual capacity with six extrusion lines ensures rapid fulfillment of large-scale orders.

ISO 9001-certified quality control across all manufacturing stages guarantees traceable consistency.

Factory-direct pricing eliminates distributor markups, delivering cost efficiency without compromising quality.

Factory Tour: Everplast’s 90,000 Ton Capacity

Strategic Manufacturing Capability

World-Class Production Infrastructure

20,000 sqm ISO 9001-certified facility in Shandong, China – engineered for high-volume B2B output

6 state-of-the-art extrusion lines with closed-loop temperature control and automated thickness monitoring

90,000 tons annual capacity – scalable production to meet seasonal or project-specific demand spikes

Full raw material traceability from supplier to finished goods

Precision Extrusion Process Flow

| Process Step | Technical Details | Quality Control Metrics |

|---|---|---|

| Melting | High-purity PP pellets melted at 200–230°C with precise melt index control | Consistent viscosity (±0.5 g/10min) |

| Die Shaping | Corrugated profile die with adjustable flute geometry (2–5mm thickness) | Dimensional tolerance ±0.1mm |

| Calibrating | Multi-stage vacuum cooling system for flatness and structural integrity | Thickness uniformity ±0.05mm across entire sheet |

| Cutting | CNC-guided laser/blade cutting with real-time alignment | Edge integrity (no burrs), length tolerance ±1mm |

Rigorous Quality Assurance Protocol

100% pre-shipment inspection via automated vision systems and manual sampling per ISO 2859-1

Impact resistance validation per ASTM D5420 (minimum 50J/m² for 2mm+ sheets)

GSM verification using calibrated scales (1200gsm+ standard for heavy-duty applications)

Batch traceability with QR-coded lot tracking for full supply chain transparency

On-site lab testing for waterproofing (ASTM D751), oil resistance, and tensile strength

Why This Matters for Your Supply Chain:

Our 90,000-ton annual capacity and 6 extrusion lines ensure zero lead-time delays for large-scale projects. Every sheet undergoes 12+ quality checkpoints – eliminating costly rework in construction, logistics, or automotive assembly lines. For procurement teams, this translates to predictable delivery schedules, consistent material performance, and 15–20% lower total cost of ownership versus fragmented suppliers.

Contact us for custom thickness/GSM specifications – we engineer solutions for your toughest job sites.

Industrial Applications & Case Studies

Industrial Applications of EVERPLAST Floor Protection Sheets

Engineered for ROI-driven durability across high-stress environments. 15+ years of manufacturing excellence with ISO 9001-certified processes.

Construction Site Protection

Heavy-duty floor shielding for concrete, tile, and hardwood during renovation or new builds. Eliminates costly rework from scratches, spills, and equipment damage.

| Feature | Specification | Benefit |

|---|---|---|

| Impact Resistance | 3-5mm thickness, 1200gsm PP corrugated structure | Withstands 500kg point loads without deformation |

| Waterproofing | Fully sealed PP material | Resists cement, paint, and chemical spills without degradation |

| Reusability | 40+ cycles | Reduces material costs by 60% vs. single-use alternatives |

Automotive Parts Transportation

Precision dunnage for high-value components during transit. Prevents vibration damage and scrap from improper handling.

| Feature | Specification | Benefit |

|---|---|---|

| Cushioning Effect | 2-3mm thickness, 800gsm PP | Absorbs 95% of shock loads during transit |

| Oil Resistance | Inherent PP properties | Withstands hydraulic fluids, lubricants, and fuel exposure |

| Reusability | 25+ cycles | Lowers dunnage costs by 45% per shipment |

Agricultural Produce Handling

Food-safe crate liners and layer pads for vegetables, fruits, and perishables. Prevents spoilage during storage and transport.

| Feature | Specification | Benefit |

|---|---|---|

| Food-Safe Material | FDA-compliant PP (no BPA) | Safe for direct contact with fresh produce |

| Moisture Barrier | Hydrophobic surface + UV stabilization | Extends shelf life by 15% in humid environments |

| Reusability | 30+ harvest cycles | Cuts crate replacement costs by 50% annually |

Logistics Bottle Layer Pads

Anti-slip interlayers for glass, beverage, and chemical containers. Prevents breakage during stacking and shipping.

| Feature | Specification | Benefit |

|---|---|---|

| Load Capacity | 3mm thickness, 1200gsm PP | Supports 1,000kg/pallet stack without deformation |

| Anti-Slip Surface | Textured PP corrugation | Eliminates 90% of container shifting during transit |

| Reusability | 35+ cycles | Reduces packaging expenses by 40% vs. cardboard |

Manufacturing Excellence: Scalable, Certified Production

Global supply chain reliability backed by industrial-scale capabilities.

| Capability | Detail | Advantage |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Zero supply chain disruptions for multi-million-unit orders |

| Extrusion Lines | 6 high-speed lines | 20% faster lead times for urgent global shipments |

| Quality Certification | ISO 9001:2015 | Traceable quality control from raw material to final shipment |

“EVERPLAST’s 1200gsm PP sheets reduced our construction site floor repair costs by 68% in 2023. The 40+ reuse cycles pay for themselves in 3 months.”

— Project Manager, China Construction Group (2023 Case Study)

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Engineered for Industrial Durability & Cost Efficiency

Factory Direct Pricing Model

Eliminate distributor markups with direct manufacturing – 15-25% cost savings vs. trading companies

90,000 tons annual production capacity with 6 fully automated extrusion lines ensures economies of scale

ISO 9001-certified processes guarantee quality without premium pricing

Rapid Deployment & Supply Chain Reliability

30% deposit initiates production; 70% balance due prior to shipment (flexible terms for strategic partners)

Sample lead time: 48 hours; standard orders delivered in 7–15 days; expedited options available

Dedicated logistics coordination for seamless global shipping with real-time tracking

Technical Engineering Support

Customizable PP corrugated sheets: GSM 420–1200g, thickness 2–5mm, any size/color

On-site application analysis for automotive, construction, and logistics projects

Free sample development with technical validation within 48 hours

| Specification | Everplast Standard | Industry Standard | Advantage |

|---|---|---|---|

| Material | Virgin Polypropylene (PP) | Recycled PP | Superior impact resistance, no contaminants |

| GSM Range | 420g – 1200g | 300g – 800g | Customizable high-GSM options for heavy-duty cushioning |

| Thickness | 2mm – 5mm | 1.5mm – 4mm | Optimized load distribution for construction sites |

| Production Capacity | 90,000 tons/year | 50,000 tons/year | Guaranteed supply for large-scale projects |

| Certification | ISO 9001:2015 | Varies | Consistent quality control across all batches |

Contact us today for a custom sample. Our engineering team will tailor solutions to your exact specifications within 48 hours.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.