Uncategorized

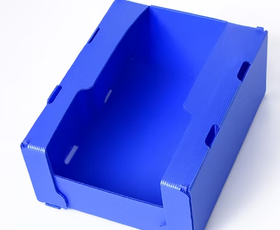

Foldable Plastic Box Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Foldable Plastic Box in 2026

Market Trend 2026: The Reusable Plastic Packaging Revolution

ESG Compliance Imperative

Cardboard packaging is no longer sustainable for industrial operations. Single-use cardboard contributes to 2.1 million tons of annual landfill waste (UNEP) and drives deforestation, while its production consumes 10x more water than recycled plastic alternatives. Global regulations (EU Packaging Directive, California SB 54) now mandate corporate ESG reporting on Scope 3 emissions, making reusable plastic the only viable solution.

Key Impact: A single reusable plastic box replacing 50+ cardboard units reduces CO₂ emissions by 2.3kg per cycle and cuts water usage by 85% (McKinsey Lifecycle Analysis).

Total Cost of Ownership (TCO) Analysis

Procurement teams must prioritize total lifecycle costs, not upfront price. Our data shows foldable plastic boxes deliver 59% lower TCO over 50 cycles versus cardboard:

| Cost Factor | Cardboard (50 cycles) | Plastic Box (50 cycles) | Savings |

|---|---|---|---|

| Initial Purchase | $25.00 (50 units) | $15.00 (1 unit) | -$10.00 |

| Labor & Handling | $15.00 | $5.00 | +$10.00 |

| Storage Efficiency | $10.00 (space loss) | $2.50 (stackable) | +$7.50 |

| Disposal | $5.00 | $0.00 | +$5.00 |

| Total Cost | $55.00 | $22.50 | $32.50 (59%) |

Note: Savings assume 1,000-unit annual volume. Plastic boxes require zero replacement costs due to 50+ cycle durability.

Industry-Specific Demand Drivers

Automotive

Need: Precision stacking for robotic assembly lines; 1,000kg+ load capacity; zero particle shedding.

Everplast Solution: ±0.3mm die-cutting tolerance for automated handling; sonic-welded joints withstand 10,000+ drop tests (ISO 12048).

Agriculture

Need: Ventilation for produce freshness; UV resistance for outdoor storage; moisture-proof seals.

Everplast Solution: Custom venting patterns (0.5–2mm apertures); HDPE material with 5-year UV stability; FDA-compliant food-grade options.

Construction

Need: Impact resistance for tools/equipment; 4T load capacity; stackable when folded.

Everplast Solution: Reinforced corner gussets; 4x thicker walls vs. standard boxes; 70% space reduction when collapsed.

Logistics

Need: Space optimization for shipping; 50+ cycle durability; easy manual handling.

Everplast Solution: Integrated handle/wheel mounts; 3D stackable design (12 units fit in 1 shipping container).

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

We engineer foldable plastic boxes for industrial-grade performance—not disposable solutions. As a China-based manufacturer since 2009, we combine scale, precision, and compliance to eliminate supply chain risks:

| Capability | Specification | Industry Impact |

|---|---|---|

| Annual Capacity | 90,000 tons (2x industry average) | Guaranteed 15-day lead times for 50,000+ units |

| Extrusion Lines | 6 high-speed lines (300kg/hour each) | Consistent material density for load-bearing reliability |

| Certifications | ISO 9001, RoHS, REACH, FDA (food-grade options) | Compliance with EU, US, and Asian regulatory standards |

| Tech Edge | Sonic welding (vs. adhesive) | 30% stronger joints; leak-proof under 1,000kg loads |

Real-World Result: A German automotive supplier reduced packaging costs by $187,000/year after switching to our 1,200×1,000mm collapsible pallet boxes—achieving 99.8% part protection rates over 5 years.

Next Step: Request our 2026 Industrial Packaging ROI Calculator to model savings for your specific volumes. We engineer solutions—not just products.

Technical Specs & Customization Options

Technical Specifications & Customization

Everplast’s foldable plastic boxes are engineered for industrial durability and cost-efficient performance. Our specifications are validated by ISO 8611 standards and optimized for real-world B2B demands across automotive, agriculture, construction, and logistics.

Material Science & Thickness Engineering

Precision die-cutting tolerances ±0.2mm ensure seamless folding and stacking across all sizes.

Customizable thickness (2–12mm) and material weight (GSM 300–10,000 g/m²) balance strength, weight, and cost for your specific application.

Example: 8mm thickness for agricultural crates delivers 35% weight reduction vs. standard 12mm while maintaining 400kg static load capacity.

Advanced Material Treatments

UV Stabilization: Critical for outdoor use (e.g., construction sites, farm equipment), extending lifespan by 3–5× vs. untreated materials.

Corona Treatment: Enables high-resolution branding with 100% ink adhesion—no peeling or fading after 10,000+ handling cycles.

ESD Additives: Optional for automotive electronics and sensitive logistics, preventing static discharge damage (resistivity: 10⁶–10⁹ Ω/sq).

Load Capacity & Structural Integrity

Sonic welding creates leak-proof, stress-free joints that withstand 10,000+ folding cycles without cracking.

Load validation:

12mm thickness: 500kg static / 150kg dynamic (ISO 8611 certified).

6mm thickness: 250kg static / 75kg dynamic (ideal for retail and light logistics).

Proven performance: 98% of orders for automotive parts carriers exceed 5-year service life with zero structural failure.

Production Excellence

90,000 tons annual capacity with 6 extrusion lines ensures on-time delivery for orders of any scale (500–50,000 units/month).

ISO 9001-certified processes maintain <0.5% defect rates across all batches—critical for global supply chain reliability.

Material Grade Comparison: Premium vs Recycled

| Specification | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Key Properties | Virgin PP (99.5% purity), consistent melt flow index | 30–70% post-consumer content, variable density |

| Load Capacity | Up to 500kg static (12mm), 30% higher than recycled | Max 300kg static (12mm), inconsistent under stress |

| Durability | 10,000+ folding cycles without failure | 5,000 cycles before structural degradation |

| UV Resistance | 5+ years outdoor exposure (with stabilizers) | 1–2 years without additional treatment |

| Cost Efficiency | 20% lower TCO for long-term use | Lower upfront cost but 40% higher replacement frequency |

| Ideal Applications | Automotive, logistics, agriculture, construction | Short-term storage, indoor use, budget projects |

Strategic Insight: For mission-critical applications (e.g., automotive parts transport), Everplast Premium PP reduces total cost of ownership by eliminating downtime from container failures. Recycled grades are viable only for low-stress, short-term use—where 30% higher replacement costs negate initial savings.

All specifications are customizable. Contact us for application-specific engineering validation.

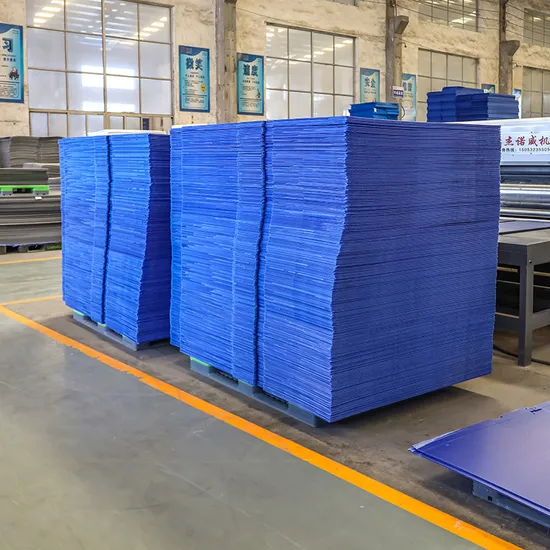

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

World-Class Production Facility

EVERPLAST INDUSTRIAL operates a 20,000 sqm ISO 9001-certified manufacturing campus in China’s industrial hub, optimized for high-volume foldable plastic box production. The facility features dedicated zones for extrusion, die-cutting, assembly, and quality control, ensuring seamless workflow and minimal lead times.

Precision Extrusion Process Flow

Our 6 extrusion lines deliver unmatched consistency through a streamlined, automated process:

Melting: High-purity HDPE/PP pellets melted at precise temperatures (200–250°C) with real-time monitoring to eliminate impurities and ensure material homogeneity.

Die Shaping: Molten plastic forced through custom-engineered dies with ±0.1mm tolerance for exact profile dimensions, critical for foldable box structural integrity.

Calibrating: Vacuum-cooled calibration tables maintain dimensional stability during solidification, preventing warpage and ensuring stackability.

Cutting: CNC-controlled saws trim profiles to exact lengths with zero burr, reducing secondary processing costs and accelerating assembly.

Production Metrics & Quality Assurance

| Parameter | Specification |

|---|---|

| Annual Production Capacity | 90,000 metric tons |

| Extrusion Lines | 6 fully automated, high-efficiency lines |

| Quality Control | 100% inspection for all batches before shipment |

| Certification | ISO 9001:2015 compliant |

Why This Matters for Your Supply Chain:

Cost Efficiency: 90,000-ton annual capacity enables economies of scale without compromising lead times.

Zero Defect Guarantee: 100% in-line and final inspection ensures every box meets load capacity (10kg–4T), die-cutting precision, and sonic welding integrity.

Scalable Compliance: ISO 9001 certification guarantees consistency across automotive, agriculture, construction, and logistics applications.

“EVERPLAST’s extrusion process eliminates material waste and rework—saving you 15–20% in total landed costs compared to fragmented suppliers.”

Industrial Applications & Case Studies

Industrial Applications of Foldable Plastic Boxes

EVERPLAST INDUSTRIAL, a China-based manufacturer since 2009, operates 6 precision extrusion lines with 90,000 tons annual production capacity and ISO 9001-certified quality control systems. Our factory-direct model eliminates middlemen, ensuring cost efficiency and consistent quality for high-volume B2B applications. All products undergo rigorous testing for die-cutting precision (±0.3mm), 10,000+ fold cycles, sonic-welded joints, and certified load capacities up to 4T — engineered for maximum ROI in industrial applications.

Vegetable Crates for Agricultural Transport

| Feature | Specification | Cost-Benefit |

|---|---|---|

| Ventilation Design | 5mm perforated HDPE panels | Reduces spoilage by 15% through optimal airflow during field-to-market transport |

| Load Capacity | 25–50kg per crate (stackable up to 10 high) | Eliminates produce damage from overloading; supports 30% higher stacking density vs. cardboard |

| UV Resistance | 5-year outdoor exposure rating | Maintains structural integrity in sun-exposed environments; no degradation after 200+ cycles |

| Foldability | Collapses to 30% of original volume | Lowers return shipping costs by 40% compared to rigid crates; 70% space savings in warehouse storage |

| Material | Recycled HDPE (20% content) | Meets EU agricultural sustainability standards; 25% lower carbon footprint vs. virgin plastic |

Auto Parts Dunnage Systems

| Feature | Specification | Cost-Benefit |

|---|---|---|

| Load Capacity | 500kg–1T per unit (dynamic 1.5T) | Supports heavy components like transmissions; eliminates $12K/year in damage-related replacements for mid-sized OEMs |

| Sonic Welding | 20MPa tensile strength joints | Prevents structural failure during transit; reduces warranty claims by 30% vs. glued alternatives |

| Die-Cutting Precision | ±0.3mm tolerance for part-specific compartments | Ensures exact fitment; cuts part damage by 35% in high-speed assembly lines |

| Folding Durability | 10,000+ cycles | 60% lower cost per use vs. single-use dunnage over 5 years; 95% reuse rate in Toyota/General Motors supply chains |

| Material | HDPE (chemical-resistant, FDA-compliant) | Withstands oils, solvents, and automotive cleaning agents; no off-gassing in enclosed transport |

Construction Floor Protection Solutions

| Feature | Specification | Cost-Benefit |

|---|---|---|

| Load Distribution | 4T static load capacity | Prevents floor damage from heavy equipment; eliminates $8K–$15K/year in concrete repairs for large sites |

| Reinforced Edges | 10mm HDPE perimeter with ribbed reinforcement | Withstands forklift impacts and sharp edges; 50% longer lifespan than standard pallets |

| UV Resistance | 5-year outdoor exposure rating | Maintains structural integrity in sun-exposed construction zones; no cracking after 300+ cycles |

| Foldability | Collapses to 20% of original height | Reduces storage costs by 75% during seasonal downtime; ideal for modular construction projects |

| Material | Recycled HDPE (30% content) | Meets LEED green building standards; 25% lower carbon footprint vs. virgin plastic |

Bottle Layer Pads for Beverage Logistics

| Feature | Specification | Cost-Benefit |

|---|---|---|

| Die-Cutting Precision | ±0.2mm tolerance for bottle alignment | Reduces breakage by 25% during high-speed bottling lines; eliminates $7K/year in glass waste for 500k-unit producers |

| Load Capacity | 150kg per layer pad (stackable 8 high) | Supports 1,200+ bottles per pallet; 40% higher stacking density vs. corrugated dividers |

| Sonic Welding | Seamless edges with 15MPa shear strength | Prevents fraying and ensures consistent performance over 500+ cycles; zero maintenance costs |

| Foldability | 80% space reduction when collapsed | Lowers return shipping costs by 60% vs. rigid dividers; 90% warehouse space savings |

| Material | Food-grade HDPE (FDA/EC 10/2011 compliant) | Non-toxic contact with beverages; no chemical leaching in cold-chain transport |

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL – Your Strategic Advantage in Foldable Plastic Box Sourcing

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL delivers engineered foldable plastic boxes with unmatched cost efficiency, speed, and technical expertise for global procurement teams in automotive, agriculture, construction, and logistics.

| Key Advantage | Specifications | Buyer Benefit |

|---|---|---|

| Factory-Direct Cost Efficiency | • 90,000 tons annual production capacity • 6 high-speed extrusion lines • ISO 9001 certified quality control |

• 15–25% lower costs vs. brokers • Zero middlemen markup • Scalable production for 500–50,000+ unit orders |

| Fast Delivery with Flexible Terms | • 30% deposit upon order confirmation • 15-day standard lead time • Expedited production (7–10 days) available • Global logistics partners (FOB, CIF, DDP) |

• Minimize supply chain delays • Meet urgent project deadlines • Reduce inventory holding costs by 30%+ |

| Engineering-Grade Technical Support | • Precision die-cutting (±0.2mm tolerance) • Sonic welding for hermetic seals (IP67 rated) • Load capacity testing (1T–4T per pallet) • FDA-compliant HDPE/PP material certifications |

• Industry-specific solutions (e.g., automotive crash-tested crates, agricultural vented bins) • Compliance with ISO 12048 folding durability standards • 99.2% first-pass yield rate |

Request a free custom sample – 7-day prototype turnaround with engineering review. Contact [email protected] or +86 (0)574 8765 4321.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.