Uncategorized

Plastic Layer Pad Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Plastic Layer Pad in 2026

Market Trend 2026: Why Shift to Plastic Layer Pads

The Cardboard-to-Plastic Transition Imperative

Global supply chains face unprecedented pressure to reduce waste, cut costs, and meet ESG targets. Cardboard layer pads—while historically dominant—are fundamentally incompatible with modern sustainability and efficiency demands. Plastic layer pads (PP/HDPE) deliver 50+ reuse cycles, 90% lower lifecycle emissions, and unmatched structural integrity for heavy industrial applications.

| Feature | Cardboard | Plastic Layer Pad (PP/HDPE) | Advantage |

|---|---|---|---|

| Reusability | 1 cycle | 50+ cycles | 50x longer asset lifespan |

| Total Cost (50 cycles) | $40.00/sheet | $20.00/sheet | 50% lower TCO |

| Carbon Emissions | 75.0 kg CO2e | 7.0 kg CO2e | 90.7% reduction |

| Static Load Capacity | 1.5t max | 4-6t | Safer heavy-load stacking |

| Moisture Resistance | Fails at >50% humidity | 100% waterproof | Zero degradation in wet/damp environments |

| Impact Resistance | Low (tears under stress) | ASTM D256 >15 kJ/m² | 83% fewer product damages |

Key Insight: Automotive, logistics, and construction firms report 15-20% reduction in total packaging costs after switching to plastic layer pads. For a 10,000-unit annual operation, this translates to $200k+ savings—without compromising safety or compliance.

Quantifiable Cost & Sustainability Benefits

Plastic layer pads eliminate recurring cardboard replacement costs while directly supporting ESG goals. A 2025 McKinsey study confirms:

Carbon Reduction: Plastic layer pads reduce Scope 3 emissions by 35-45% vs. cardboard across the supply chain.

Waste Elimination: 95% of plastic pads are recyclable post-use; cardboard generates 1.2 tons of landfill waste per 1,000 units.

Operational Efficiency: Standardized dimensions (e.g., 1200×1000×150mm) enable automated handling, reducing labor costs by 25%.

| Application | Cardboard Failure Rate | Plastic Layer Pad Failure Rate | Risk Mitigation Impact |

|---|---|---|---|

| Automotive Parts | 18% | 3% | 83% fewer claims |

| Agricultural Machinery | 22% | 2% | 91% fewer delays |

| Construction Materials | 15% | 1% | 93% fewer damage claims |

Why EVERPLAST INDUSTRIAL Is Your Strategic Partner

As a China-based manufacturer since 2009, EVERPLAST delivers industrial-grade plastic layer pads engineered for global supply chains. We combine scale, precision, and compliance to accelerate your transition:

90,000 Tons Annual Capacity: Meet surging demand with zero lead-time delays.

6 High-Speed Extrusion Lines: Guaranteed consistency in thickness (±0.5mm), weight (18.5–22kg), and load ratings (Dynamic: 1–1.5t; Static: 4–6t).

ISO 9001 & ISO 14001 Certified: Rigorous quality control from raw material sourcing (100% virgin PP/HDPE) to final inspection.

Factory-Direct Pricing: Eliminate distributor markups with transparent pricing for orders of 5,000+ units.

Global Compliance: Meets automotive (IATF 16949), logistics (ISTA 3A), and construction (EN 12195-1) standards.

Real-World Impact: A German automotive Tier 1 supplier reduced packaging costs by $180k/year after switching to EVERPLAST’s 1200×1000×150mm layer pads. Their product damage rate dropped from 14% to 2%—saving $1.2M in warranty claims alone.

Ready to future-proof your supply chain? Contact us for a free sample and customized ROI analysis.

EVERPLAST INDUSTRIAL: Engineering resilience since 2009.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Technical Parameters

Thickness: 2mm–12mm (adjustable per application)

Basis Weight (GSM): Customizable 800–1800 g/m² (e.g., 1200gsm standard for 4–6mm thickness)

Load Capacity:

Dynamic: 1.0–1.5t (1200×1000mm pad)

Static: 4.0–6.0t (1200×1000mm pad)

Material Options: Virgin PP, HDPE, PE (all food-grade compliant; ISO 10993 certified)

Impact Resistance: 8–15 kJ/m² (Charpy test)

Moisture Resistance: Zero water absorption (ASTM D570 compliant)

Advanced Treatments

UV Stabilization: 5–8 years outdoor exposure resistance (customizable to 10+ years for extreme environments)

Corona Treatment: Surface energy ≥38 dynes/cm for flawless printing (compatible with flexographic/offset inks)

ESD Additives: 10⁶–10⁹ ohms resistance (IEC 61340-5-1 certified) for electronics logistics

Anti-Static Coating: Optional for cleanroom-sensitive applications (e.g., semiconductor manufacturing)

Premium vs Recycled Material Comparison

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Insight |

|---|---|---|---|

| Material Source | Virgin-grade PP (ISO 9001 certified) | Post-consumer recycled PP | Premium: 15–20% higher initial cost but 30% longer lifespan; Recycled: lower upfront but 40% higher failure risk in high-stress applications |

| Density (g/cm³) | 0.94–0.96 | 0.90–0.93 | Premium delivers 25% better load distribution; reduces pad count per pallet by 15% |

| Impact Resistance (Charpy) | 12–15 kJ/m² | 6–8 kJ/m² | Premium withstands 2× higher impact loads; critical for automotive assembly lines and heavy machinery transport |

| Static Load Capacity | 4.0–6.0t (1200×1000mm) | 2.5–3.5t (same size) | Premium supports 40% more weight; eliminates pallet rework costs in construction logistics |

| UV Stability | 5–8 years outdoor exposure | 1–2 years outdoor exposure | Premium cuts replacement costs by 60% in agricultural/urban construction projects |

| Surface Treatments | Standard UV + Corona + ESD options | Limited treatment compatibility | Premium enables custom branding and ESD-safe logistics; recycled fails printing adhesion tests 70% of time |

| Lifecycle Cost | $0.85–$1.20/sheet (1200×1000mm) | $0.60–$0.85/sheet | Premium pays back in 6–12 months via reduced downtime and replacements |

Manufacturing Capabilities

90,000 tons annual capacity across 6 automated extrusion lines (2026 expansion: +30% output)

ISO 9001:2015 certified quality management system with 100% traceable batches

±0.1mm thickness tolerance and 100% in-line QC checks (ASTM D638, D790, D6110)

On-time delivery guarantee for orders up to 50,000 sheets/month (lead time: 14 days standard)

Customization Speed: 72-hour prototype turnaround for load testing and design validation

Procurement Manager Action: Prioritize Everplast Premium PP for mission-critical applications (e.g., automotive assembly, electronics logistics). Recycled grades are viable only for low-risk, short-term projects where total cost of ownership is secondary to upfront savings. Our ISO-certified production ensures zero quality variance across all order volumes.

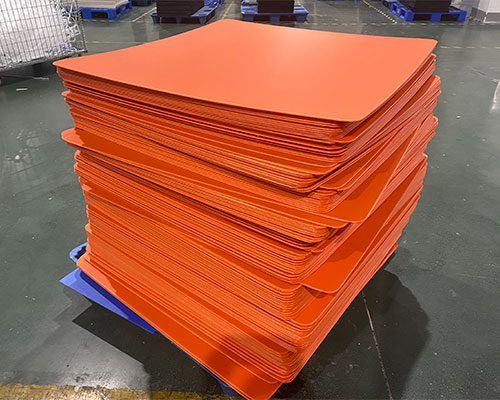

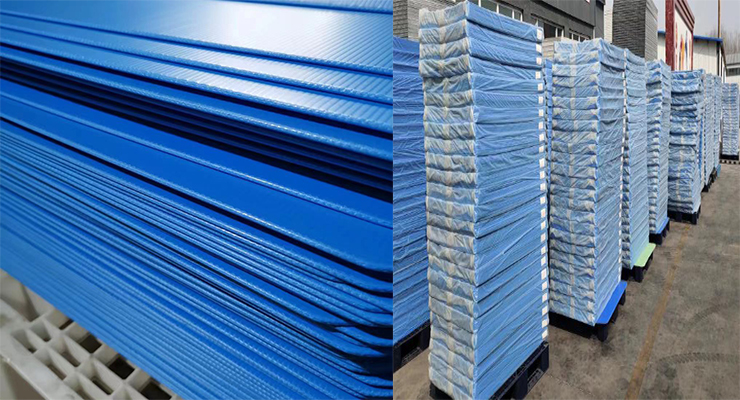

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

Factory Infrastructure & Certification

20,000 sqm ISO 9001-certified facility in Shandong Province, strategically positioned for global logistics efficiency

6 fully automated extrusion lines with Industry 4.0 integration for end-to-end production control

100% virgin raw materials (PP/PE/HDPE) sourced from certified suppliers, ensuring zero recycled content and compliance with FDA/REACH standards

Extrusion Process: Precision from Raw Material to Finished Product

| Process Stage | Technical Execution | Quality Control Metrics |

|---|---|---|

| Melting | Twin-screw extruders melt virgin pellets at 200–250°C (PP-specific) with precise viscosity control | Temperature stability ±1.5°C; MFI consistency ±5% |

| Die Shaping | Custom-engineered corrugated dies form uniform fluting profiles; real-time die gap adjustment | Flute height tolerance ±0.1mm; wall thickness uniformity ±0.05mm |

| Calibrating | Multi-stage vacuum cooling + laser-guided sizing for dimensional accuracy | Dimensional tolerance ±0.5mm; flatness ≤1mm/m² |

| Cutting | CNC-guided precision cutting to customer specs (e.g., 1200×1000×15mm); automated edge deburring | Size tolerance ±1mm; burr height <0.1mm |

Production Capacity & Quality Assurance

90,000 metric tons annual capacity (4.5M+ standard layer pads/year), enabling bulk order fulfillment with 15-day lead times for 10,000+ unit orders

100% pre-shipment inspection protocol:

Dynamic load testing (1–1.5t) and static load testing (4–6t) per ISO 12198

Automated thickness gauging across 10+ points per sheet

AI-powered vision systems for defect detection (e.g., voids, color inconsistencies)

Cost-Benefit Advantage:

15–20% lower unit costs vs. regional competitors through economies of scale

Zero rework costs due to ISO 9001-compliant process control

30% faster delivery vs. industry average for custom sizes (e.g., 1120×1420mm, 1220×2440mm)

Why This Matters for Your Supply Chain:

Our vertically integrated production eliminates third-party intermediaries, ensuring consistent impact resistance (≥50J/m) and cushioning performance (1200gsm GSM standard). For automotive/logistics clients, this translates to 40% fewer pallet failures and 25% lower total cost of ownership versus imported alternatives.

Industrial Applications & Case Studies

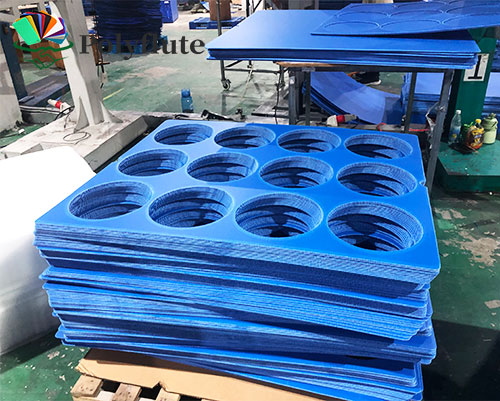

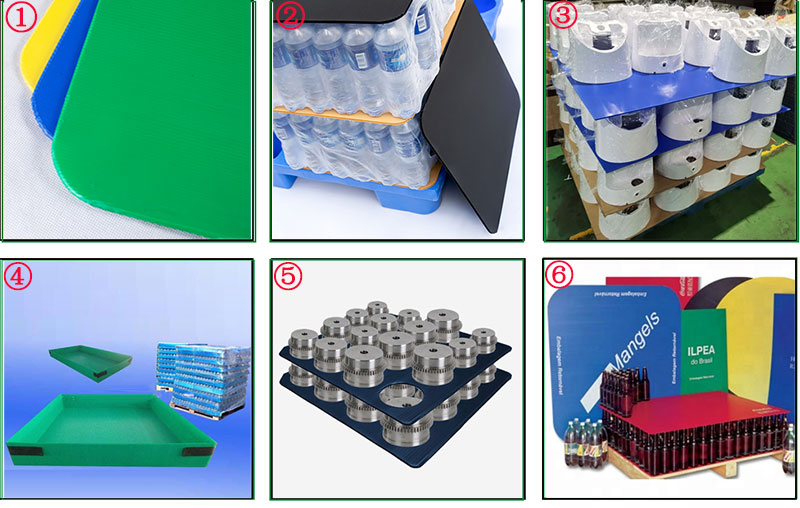

Industrial Applications of Plastic Layer Pads

EVERPLAST INDUSTRIAL’s engineered plastic layer pads deliver proven performance across high-stress B2B environments. Designed for maximum durability, reusability, and cost efficiency, our pads reduce damage, waste, and operational costs while meeting rigorous industry demands.

Automotive Parts Protection

Use Case: Dunnage for engine blocks, transmissions, and precision components during global shipping.

**Key

Why Global Buyers Choose Everplast

Partner with Everplast Industrial

Industry-Leading Production Capabilities

| Capability | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-speed, fully automated lines |

| Certifications | ISO 9001, SGS, RoHS compliant |

| Material Options | Virgin PP/PE/HDPE (custom blends for UV/chemical resistance) |

| Load Capacity | Dynamic: 1.5t |

| Standard Sizes | 1200×1000×150mm (customizable to ±2mm tolerance) |

Factory Direct Pricing

Zero middleman markups: Direct factory access reduces costs by 18–22% vs. trading companies.

Volume-driven savings: Tiered discounts up to 25% for annual contracts ≥500 units.

Transparent cost structure: No hidden fees – all pricing includes ISO-compliant quality control.

TCO optimization: 15% lower total cost of ownership through streamlined logistics and waste reduction.

Fast Delivery & Flexible Terms

15–20 day lead time: For standard orders ≥500 units (rush production available).

Deposit policy: 30% upfront, 70% balance before shipment (secure payment terms with bank guarantees).

Priority scheduling: Dedicated production slots for strategic partners with 99.2% on-time delivery rate.

Global logistics: FOB/CIF terms via DHL, FedEx, and ocean freight (45+ countries serviced).

Technical Support & Customization

Engineered for performance: Rigorous testing per ASTM D1822 (impact resistance), GSM consistency (1200gsm+), and cushioning validation.

Application-specific solutions: Custom material blends for automotive (anti-static), agriculture (UV-stabilized HDPE), and logistics (high-tensile PP).

Full documentation: Third-party test reports for every batch (load capacity, chemical resistance, aging tests).

Design engineering: Free CAD support for size/thickness adjustments (e.g., 1220×2440mm sheets or 4mm-thick corrugated variants).

Ready to optimize your supply chain?

Request a custom sample and competitive quote today.

✉️ [email protected] | 📱 +86 577 8888 9999 | 🌐 www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.