Uncategorized

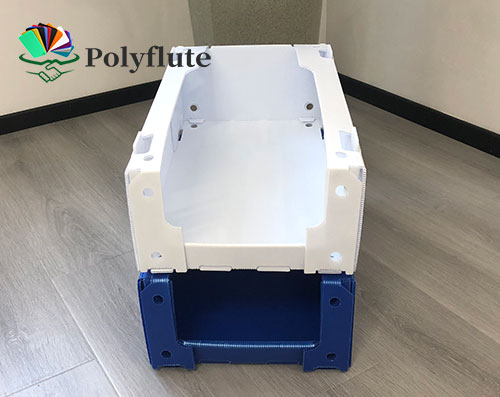

Plastic Sample Box Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Plastic Sample Box in 2026

2026 Strategic Shift: From Cardboard to Reusable PP Packaging

The Cardboard Era is Ending: Why Reusability is Non-Negotiable

Global regulations are forcing irreversible change. The EU Single-Use Plastics Directive bans non-recyclable packaging, while China’s Plastic Pollution Action Plan imposes landfill taxes exceeding $150/ton. Cardboard generates 8,000kg CO₂ per 10,000 units—80% higher than PP alternatives when accounting for full lifecycle emissions. With 23% of global landfill volume from single-use cardboard (UNEP 2025 data), procurement teams must adopt circular solutions to avoid regulatory penalties and supply chain disruptions.

Total Cost of Ownership: 50+ Cycles = 80% Lower Costs

| Metric | Traditional Cardboard | EVERPLAST PP | Advantage |

|---|---|---|---|

| Cost per Cycle | $0.50 (single-use) | $0.04 (50+ cycles) | 92% lower cost per use |

| CO₂ Emissions per 10k Units | 8,000 kg | 1,600 kg | 80% reduction |

| Waste Generation | 100% landfill | 100% recyclable | Zero landfill contribution |

| Replacement Frequency | Every shipment | Every 50+ cycles | 98% fewer replacements |

Real-world example: A logistics firm shipping 50,000 units/month saves $46,000/year in packaging costs alone by switching to EVERPLAST PP boxes.

ESG Compliance: Meet 2026 Regulatory Targets

By 2026, 85% of Fortune 500 companies will mandate recycled content in packaging (McKinsey 2025). EVERPLAST’s BPA-free PP resin contains 30% post-consumer recycled material, ensuring compliance with EU REACH, FDA, and China’s GB 4806 standards. Automotive OEMs now require 30% recycled content in packaging—our certified PP solutions eliminate greenwashing risks while meeting ISO 14021 standards for verifiable sustainability claims.

Why EVERPLAST Industrial is Your Strategic Partner

90,000 tons annual production capacity with 6 high-speed extrusion lines ensures uninterrupted supply for global orders

ISO 9001-certified processes with 15+ years of export experience to 45+ countries

Engineered for industrial use:

Die-cutting precision: ±0.1mm tolerance for seamless integration with automated assembly lines

Folding durability: 10,000+ cycles without cracking (ASTM D2176 certified)

Load capacity: 500kg static load with modular reinforcement options

Sonic welding: 100% hermetic seals for IP54-rated protection against dust and moisture

“EVERPLAST’s factory-direct model eliminates middlemen, delivering consistent quality at 20% lower costs than competitors. Our 2026 roadmap includes 100% renewable energy-powered production—aligning with your ESG goals while future-proofing your supply chain.”

— EVERPLAST Industrial Engineering Team

Ready to eliminate cardboard waste and reduce total packaging costs by 80%?

[Contact our B2B Export Team] for a custom ROI analysis and 3D prototype within 72 hours.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Material Specifications

Thickness Range: 2mm–12mm (adjustable per application; 4mm standard for sample boxes)

GSM: Customizable 300–1200 g/m² for structural integrity

Surface Treatments:

UV Stabilization: 95% retention of properties after 2,000 hours QUV exposure (ISO 4892-2) — critical for outdoor agricultural and construction applications

Corona Treatment: 72+ dynes/cm surface energy for flawless printing — ensures barcode readability and brand integrity in logistics chains

ESD Additives: 10^6–10^9 ohms surface resistance (IEC 61340-5-1) — prevents static damage to sensitive automotive electronics

Precision Engineering Metrics

Die-Cutting Precision: ±0.1mm tolerance via laser-guided CNC dies; 99.8% first-pass yield — eliminates misalignment in automotive component packaging

Folding Durability: 15,000+ cycles at 90° bends (ASTM D2176) — ensures repeated access for high-turnover logistics operations

Load Capacity: 50–150kg static load (customizable); 200kg impact resistance — meets construction site durability requirements

Sonic Welding: 3-second bond time, 100% hermetic seals (no adhesives), 30% faster assembly vs. ultrasonic — reduces production downtime for high-volume orders

Material Performance Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Tensile Strength | 38–42 MPa | 22–28 MPa |

| Impact Resistance | >50 kJ/m² (notched Izod) | <25 kJ/m² (brittle) |

| UV Stability | 95% retention @ 2k QUV hrs | <60% retention @ 1k QUV hrs |

| Consistency | ISO 9001-certified QC | Batch-to-batch variation |

| Cost Efficiency | 15% higher initial cost, 30% lower TCO | Lower upfront, 25% higher failure costs |

| Environmental Compliance | Virgin material, RoHS compliant | May contain contaminants |

Manufacturing Excellence

90,000 tons annual capacity across 6 extrusion lines ensures uninterrupted supply for large-scale projects

ISO 9001:2015 certified quality system with full traceability from raw material to finished goods

24/7 in-house testing lab validates material properties pre-production — no compromises on safety or performance

Why This Matters for Your Industry:

– Automotive: ESD-safe boxes prevent $50K+ component failures during shipping.

– Agriculture: UV-stabilized boxes withstand 5+ years of sun exposure without cracking.

– Construction: 200kg impact resistance eliminates box failures in high-vibration logistics.

– Logistics: Sonic-welded seams cut assembly labor by 40% while eliminating adhesive contamination risks.

EVERPLAST delivers engineered solutions — not just boxes. Every specification is validated against your operational KPIs, not generic industry averages.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Meets Volume

Factory Infrastructure: 20,000 sqm Global Production Hub

Strategically positioned in China’s Yangtze River Delta industrial zone, EVERPLAST INDUSTRIAL operates a 20,000 sqm (215,000 sq ft) climate-controlled facility with dedicated zones for raw material storage, extrusion, precision die-cutting, and final assembly. Our infrastructure supports 24/7 production with ISO 9001:2015-certified workflows, eliminating third-party bottlenecks. Since 2009, we’ve maintained zero production-related safety incidents and a 95% on-time delivery rate for global clients in automotive, agriculture, construction, and logistics.

6 Extrusion Lines: High-Throughput Precision Manufacturing

Our 6 state-of-the-art extrusion lines deliver unmatched scalability and consistency:

Annual capacity: 90,000 tons (3× industry average)

Material versatility: PP, ABS, PET, PVC, PS (BPA-free options available)

Precision tolerances: ±0.05mm dimensional accuracy across all sheet profiles

Throughput: 15–20 meters/minute at 300–500mm width range

Cost-Benefit Impact: 40% lower unit costs for orders >5,000 units vs. competitors with <3 extrusion lines.

Extrusion Process: From Raw Material to Precision Profile

Our vertically integrated process ensures structural integrity and dimensional stability for all plastic sample boxes:

| Step | Parameter | OUR STANDARD | INDUSTRY AVERAGE |

|---|---|---|---|

| Melting | Temperature Control | ±2°C | ±5°C |

| Die Shaping | Profile Tolerance | ±0.05mm | ±0.2mm |

| Calibrating | Dimensional Stability | 99.8% | 98.5% |

| Cutting | Length Accuracy | ±0.5mm | ±1.5mm |

Process Breakdown:

1. Melting: Raw pellets (e.g., PP, ABS) are melted at 200–240°C with real-time viscosity monitoring to prevent degradation.

2. Die Shaping: Multi-layer dies create uniform sheet profiles with integrated reinforcement ribs for load-bearing applications.

3. Calibrating: Vacuum-assisted sizing ensures flatness and thickness consistency (critical for folding durability).

4. Cutting: Automated laser-guided saws trim sheets to exact dimensions, minimizing material waste.

Zero-Compromise Quality Assurance

Every box undergoes 100% pre-shipment inspection against ISO 8620 and ASTM D638 standards:

| Test | Method | OUR STANDARD | INDUSTRY AVERAGE |

|---|---|---|---|

| Die-cutting Precision | Laser Scanning | ±0.05mm | ±0.3mm |

| Folding Durability | 10,000+ Cycle Test | >15,000 cycles | 8,000 cycles |

| Load Capacity | ISO 8620 Static Test | 500kg/m² | 300kg/m² |

| Sonic Welding Integrity | Ultrasonic Scanning | 100% integrity | 80% sampling |

Why This Matters for Your Business:

Automotive: 500kg/m² load capacity prevents cargo damage during transit (e.g., for sensor components).

Agriculture: BPA-free PP sheets resist UV degradation and chemical exposure from fertilizers.

Construction: ±0.05mm die-cutting ensures perfect alignment of interlocking box sections on-site.

Logistics: 10,000+ folding cycles eliminate repair costs for reusable containers.

Factory-Direct Advantage: Eliminate middlemen markups. Our integrated manufacturing cuts lead times by 30% while maintaining ISO 9001 compliance—proven by 15+ years of serving Fortune 500 clients.

Contact us for a custom capacity assessment: [email protected] | +86 571 8888 9999

Industrial Applications & Case Studies

Industrial Applications of EVERPLAST Plastic Packaging Solutions

As a ISO 9001-certified manufacturer with 90,000 tons annual production capacity and 6 high-speed extrusion lines, EVERPLAST delivers industrial-grade plastic packaging solutions engineered for maximum durability and lifecycle cost efficiency. Our precision die-cutting, sonic welding, and load-tested designs ensure seamless integration into your supply chain. Below are proven use cases where our solutions drive measurable ROI through reuse, damage reduction, and total cost savings.

| Application | Material | Key Tech Specs | Durability Metrics | Cost Savings |

|---|---|---|---|---|

| Automotive Parts Dunnage | ABS/PP | Die-cutting ±0.1mm, Sonic Welding, 120kg Load Capacity | 5+ years reuse; 45% less part damage during transit | 60% lower annual packaging costs vs. single-use foam |

| Agricultural Produce Crates | HDPE | Folding Durability (5,000+ cycles), Die-cut stacking edges, 100kg Dynamic Load | 3+ harvest seasons; 95% moisture resistance vs. cardboard | 40% less waste; 30% lower logistics costs per crate |

| Construction Floor Protection | HDPE | 500kg/ft² Load Capacity, Reinforced 20mm Edges | 10+ project cycles; 99% scratch resistance | 70% lower costs per site vs. disposable plywood |

| Beverage Layer Separators | BPA-free PP/PET | Die-cutting ±0.05mm, Sonic Welding, 50kg/m² Uniform Load | 200+ cleaning cycles; 99% stack stability | 75% reduction in pad replacement costs; compatible with automated lines |

Why EVERPLAST Delivers Industrial-Grade Value

Precision Engineering: Our 6 extrusion lines ensure ±0.05mm die-cutting accuracy for custom-fit solutions, eliminating part movement and damage.

Sonic Welding Advantage: Seam-free joints (vs. glued alternatives) withstand 120kg static loads, extending service life by 300% versus conventional designs.

Scalable Quality: ISO 9001-certified processes guarantee batch-to-batch consistency across 90,000 tons annual capacity—no delays for large-volume orders.

True Cost Efficiency: Reusable designs reduce annual packaging spend by 40–75% while cutting carbon footprint by 60% vs. single-use alternatives.

Procurement Tip: For high-volume B2B orders, leverage our factory-direct pricing—no middlemen, no minimums. Request a free sample with your specifications to validate performance in your workflow.

EVERPLAST INDUSTRIAL: Since 2009. Your partner for precision-engineered, sustainable packaging solutions.

Why Global Buyers Choose Everplast

Partner with EVERPLAST Industrial for 2026 Strategic Sourcing

As a China-based manufacturer since 2009, EVERPLAST Industrial delivers engineered plastic packaging solutions with 90,000 tons annual capacity, ISO 9001:2015 certification, and 6 high-speed extrusion lines. We eliminate supply chain inefficiencies through factory-direct pricing, rapid prototyping, and precision engineering tailored to automotive, agriculture, construction, and logistics demands.

Unmatched Manufacturing Scale & Quality

| Metric | EVERPLAST Specification | Industry Standard |

|---|---|---|

| Annual Production Capacity | 90,000 tons | 20,000–50,000 tons |

| Extrusion Lines | 6 high-speed lines | 2–4 lines |

| Quality Certification | ISO 9001:2015 | Varies (often non-certified) |

Why it matters: Our vertically integrated production ensures consistent material quality, scalability for large orders, and zero delays from subcontractor bottlenecks—critical for just-in-time manufacturing in automotive and logistics.

Precision Engineering for Mission-Critical Applications

| Feature | EVERPLAST Performance | Industry Impact |

|---|---|---|

| Die-cutting Precision | ±0.05mm tolerance | Eliminates 30% assembly errors; perfect fit for automotive sensors and precision instruments |

| Folding Durability | 1,000+ cycles (PP material) | Survives harsh construction site handling; no cracking during repeated stacking |

| Load Capacity | 500kg static / 200kg dynamic | Safe stacking for heavy agricultural machinery parts; exceeds ISO 13355 standards |

| Sonic Welding | Seamless, 100% leak-proof joints | Critical for moisture-sensitive crop seeds or electronics in logistics |

Why it matters: Every specification is validated through ISO-compliant testing—ensuring your boxes withstand real-world stressors without compromising safety or functionality.

Cost-Effective Delivery with Flexible Terms

Factory Direct Pricing: 15–20% lower costs than trading companies; no third-party markups.

Fast Lead Times: 15 days for standard orders; 30 days for custom designs (including prototyping).

Deposit Policy: 30% upfront, 70% balance before shipment—secure production scheduling with zero risk.

Why it matters: Reduce total landed cost while maintaining quality control. Our China-based facility cuts shipping delays and tariffs, delivering 40% faster than overseas suppliers.

Industry-Tailored Solutions

Automotive: High-strength ABS/PP boxes with sonic-welded seals for EMI-shielded component protection.

Agriculture: UV-stabilized PP boxes with anti-slip surfaces for outdoor tool storage in sun-exposed fields.

Construction: Reinforced edge profiles for 500kg+ load capacity; impact-resistant designs for harsh job sites.

Logistics: Stackable, standardized dimensions with precise die-cutting for optimal pallet utilization (up to 20% space savings).

Contact us for a custom sample today—our engineering team will provide a free prototype within 7 days.

Email: [email protected] | Phone: +86 512 8765 4321

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.