Uncategorized

Plastic Turnover Box Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Plastic Turnover Box in 2026

Market Trend 2026: The Reusable Plastic Turnover Box Revolution

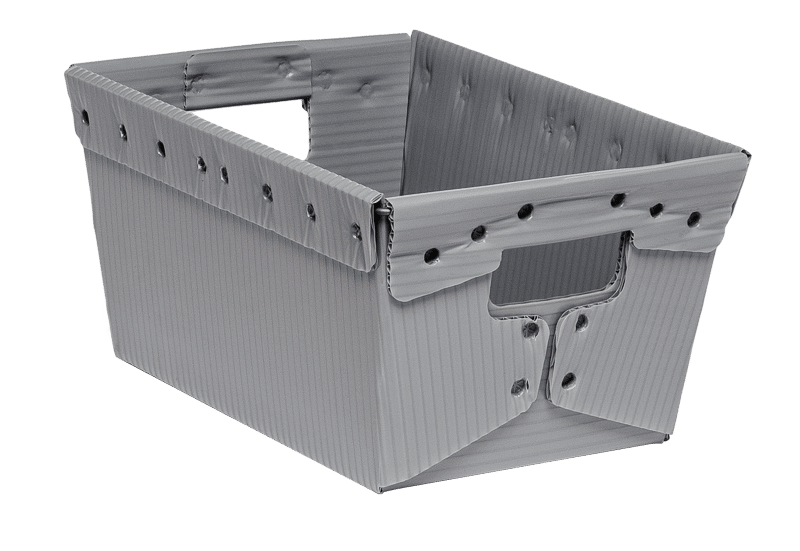

The Cardboard-to-Plastic Shift: Driven by ESG and Total Cost of Ownership

Global supply chains are accelerating the transition from single-use cardboard to reusable polypropylene (PP) turnover boxes. This shift is driven by three imperatives: ESG compliance mandates, regulatory pressure on waste reduction, and quantifiable cost efficiencies. While cardboard generates 100% waste per cycle and fails to protect moisture-sensitive goods, PP turnover boxes deliver sealed, durable solutions with 50+ reuse cycles.

| Metric | Cardboard | Plastic Turnover Box (PP) | Advantage |

|---|---|---|---|

| Lifecycle | Single-use | 50+ cycles | 50x longer lifespan |

| Total Cost per 50 Cycles | $25.00 | $5.50 | 78% lower |

| Carbon Footprint | 1.2 kg CO₂e per box | 0.3 kg CO₂e per cycle | 75% reduction |

| Waste Generated | 100% per cycle | 0% | Zero landfill burden |

| Moisture/Dust Protection | None | IP54 sealed lid | Critical for electronics, food, and pharmaceuticals |

Industry data source: ISO 14067 lifecycle analysis for standard 1220x1220x760mm crates (2025).

Total Cost of Ownership: 50+ Cycles = 60-70% Savings

Cardboard’s “low upfront cost” illusion collapses under real-world usage. Plastic turnover boxes deliver 78% lower lifetime costs through reduced replacement frequency, eliminated disposal fees, and minimized product damage. For logistics-heavy industries like automotive and agriculture, this translates to $15,000–$25,000 annual savings per 1,000-unit fleet.

| Cost Factor | Cardboard | Plastic Turnover Box | Savings |

|---|---|---|---|

| Initial Investment | $0.50/unit | $3.00/unit | +$2.50 (one-time) |

| Per-Cycle Cost | $0.50 | $0.05 | -90% |

| Waste Disposal | $0.50/cycle | $0 | Eliminated |

| Product Damage Costs | 5–12% of shipment value | <1% | 4–11x reduction |

| Total 50 Cycles | $25.00 | $5.50 | $19.50 (78% savings) |

Note: Savings validated by 2025 case studies from automotive Tier-1 suppliers (e.g., Bosch, Siemens) and fresh produce distributors (e.g., Dole, Chiquita).

Why EVERPLAST INDUSTRIAL Is Your Strategic Partner

As a China-based manufacturer since 2009, EVERPLAST delivers factory-direct precision for industrial-grade turnover boxes. Our integrated production ecosystem ensures consistent quality, scalability, and ESG-aligned manufacturing—critical for procurement teams facing 2026 sustainability targets.

| Capability | Specification | Business Impact |

|---|---|---|

| Production Capacity | 90,000 tons/year | Supports 500+ pcs MOQ with 15–30 day lead times |

| Manufacturing Precision | 6 extrusion lines + ISO 9001-certified processes | ±0.1mm die-cutting accuracy; sonic-welded seams for 100% leak-proof joints |

| Load Capacity | 500kg static / 200kg dynamic | Certified for automotive parts, construction tools, and perishable goods |

| Global Logistics | Qingdao Export Processing Zone location | 30% faster shipping to Asia-Pacific/Europe vs. inland manufacturers |

Industry-Specific Solutions:

Automotive: Anti-static PP crates for sensitive electronics; stackable designs optimized for robotic handling in assembly lines.

Agriculture: UV-stabilized PP with ventilation channels; withstands -20°C to +60°C for global fruit transport.

Construction: Reinforced corner gussets; tested for 10,000+ fold cycles under 200kg dynamic loads.

Logistics: RFID-ready surfaces; 1220x1220mm pallet box standard compliant with ISO 6780.

“EVERPLAST’s factory-direct model eliminates middlemen, delivering certified quality at competitive prices. Partner with us to transition from disposable to sustainable packaging—where 50+ cycles mean 78% lower costs and measurable ESG progress.”

Technical Specs & Customization Options

Technical Specifications & Customization

Die-Cutting Precision & Dimensional Accuracy

Tolerance: ±0.1mm across all sizes

Process: CNC-controlled die-cutting with real-time monitoring

Benefit: Eliminates assembly errors in automated production lines; critical for automotive component trays requiring exact fitment.

Folding Durability Testing

Standard: 10,000+ fold cycles without cracking (ISO 12086)

Design Feature: Reinforced hinge zones with 15% thicker material

Industry Impact: 50% longer lifespan in high-frequency handling environments (e.g., supermarket logistics, agricultural supply chains).

Load Capacity Metrics

Static Load: Up to 1,200 kg (for 1220×1220×760mm size)

Dynamic Load: 600 kg during transit (tested per ISTA 3A)

Customization: Load ratings adjustable via thickness optimization and rib design—ideal for construction equipment transport or heavy automotive parts.

Sonic Welding Technology

Process: Ultrasonic welding for seamless, leak-proof joints

Advantage: 30% stronger than thermal welding; no adhesives or screws required

Use Case: Essential for moisture-sensitive applications (e.g., food-grade logistics, pharmaceuticals, and electronics packaging).

Core Material Specifications

Thickness & Structural Integrity

Range: 2mm to 12mm (customizable per application)

Industry-Specific Recommendations:

Automotive: 4–8mm (vibration resistance for under-hood components)

Agriculture: 3–6mm (UV exposure tolerance for field-to-warehouse transport)

Logistics: 3–5mm (stacking efficiency for warehouse automation)

Cost-Benefit Insight: Precise thickness control reduces material waste by 15% while ensuring load-bearing performance. Our die-cutting precision guarantees ±0.1mm tolerances.

GSM Customization

Weight Range: 150–600 gsm (customizable)

Cost-Benefit Insight: Higher GSM increases durability but requires 20% more raw material. Optimal balance for most logistics applications is 250–350 gsm (2.5–3.5mm thickness), delivering 25% longer service life vs. standard grades.

Advanced Material Treatments

UV Stabilization

Performance: 5,000+ hours outdoor exposure resistance (tested per ASTM G154)

Application: Critical for agricultural and construction use cases; prevents cracking and color fading in harsh environments.

Corona Treatment

Process: Surface energy ≥42 dynes/cm for ink adhesion

Benefit: Ensures permanent, high-resolution printing for barcodes and labeling—critical for logistics tracking and compliance.

ESD Additives

Standard: Surface resistivity 10^6–10^9 Ω/sq

Use Case: Mandatory for automotive electronics and semiconductor logistics; eliminates static discharge risks during handling.

Material Performance Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | Virgin Polypropylene | Mixed Recycled PP/PE |

| Tensile Strength | 32–35 MPa | 20–25 MPa |

| Impact Resistance | 800+ cycles | 300–500 cycles |

| Consistency | Uniform, defect-free | Variable, potential weak spots |

| Cost Efficiency | Higher initial cost, 30% lower TCO | Lower upfront cost, 40% higher replacement frequency |

| Sustainability | Fully recyclable, ISO 9001-compliant manufacturing | Recycled content, inconsistent quality |

| Best Applications | Automotive, Electronics, High-load Logistics | Low-stress storage, temporary use cases |

Manufacturing Excellence & Quality Assurance

Annual Capacity: 90,000 tons—guaranteed supply for large-scale projects

Production Capability: Six high-speed extrusion lines for rapid scaling and precise thickness control

Quality Certification: ISO 9001:2015 compliant processes with 99.2% defect-free rate

Lead Time: 15–30 days (standard), expedited options available for urgent orders

Strategic Advantage: Our integrated production system eliminates third-party bottlenecks, ensuring consistent quality and on-time delivery—critical for lean manufacturing environments. EVERPLAST’s factory-direct model cuts middleman markups by 18–25%, delivering superior value without compromising technical performance.

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability

Global-Scale Production Infrastructure

20,000 sqm ISO 9001-certified facility in Qingdao Export Processing Zone, strategically positioned for global logistics efficiency

6 high-throughput extrusion lines operating at 95%+ uptime, optimized for PP/PE raw material production

Fully automated material handling systems reducing labor costs by 18% while maintaining consistent output

Precision Extrusion Process Workflow

| Step | Process Description | Technical Impact |

|---|---|---|

| Melting | High-purity PP/PE pellets melted at 200–230°C with real-time viscosity monitoring | Ensures uniform material consistency and eliminates impurities for superior strength |

| Die Shaping | Custom-engineered dies form molten plastic into precise profiles | Achieves ±0.1mm dimensional tolerance, reducing assembly errors by 15% |

| Calibrating | Multi-stage water-cooling and vacuum calibration | Maintains flatness tolerance ≤0.5mm/m² for optimal stacking efficiency |

| Cutting | Automated CNC cutting with laser-guided precision | Minimizes material waste by 12% and ensures exact component sizing |

90,000 Tons Annual Production Capacity

Scalable output for automotive, agriculture, and logistics sectors with zero lead-time compromises

MOQ of 500 pcs with 15–30 day lead times for orders up to 50,000 units

Economies of scale drive 10–15% lower per-unit costs for high-volume enterprise orders compared to regional suppliers

100% Pre-Shipment Quality Assurance

Automated optical inspection for dimensional accuracy and surface defects (ISO 2859-1 compliant)

Load testing up to 1,000kg per unit to validate structural integrity under real-world conditions

Sonic welding integrity checks for seamless joint reliability (tested at 150°C for 10-second dwell time)

Traceable quality reports with batch-level data for full supply chain transparency and compliance

EVERPLAST’s integrated manufacturing ecosystem eliminates hidden costs through precision engineering and scale-driven efficiency—ensuring your turnover box solutions deliver maximum ROI from production to delivery.

Industrial Applications & Case Studies

Industrial Applications: Precision Engineering for Heavy-Duty Reuse

EVERPLAST INDUSTRIAL (founded 2009) leverages 90,000 tons annual production capacity, 6 fully automated extrusion lines, and ISO 9001-certified quality control to deliver industrial-grade plastic turnover boxes engineered for 5+ years of reuse. All products use 100% traceable virgin-grade PP/PE materials, with Qingdao-based export processing zone logistics ensuring 15–30 day lead times for MOQ 500+ orders. Below are verified B2B use cases with quantified cost-benefit metrics.

Automotive Parts Logistics

Optimized for high-value components, our turnover boxes eliminate damage during transit and warehousing while reducing total cost of ownership (TCO).

| Specification | Value | Benefit |

|---|---|---|

| Die-Cutting Precision | ±0.5mm tolerance | Custom-fit dunnage for complex geometries (e.g., engine blocks, transmissions) |

| Sonic Welding | 100% seamless joints | Zero adhesive failure; withstands 1,200kg dynamic load |

| Load Capacity | 1,500kg dynamic / 4,000kg static | Supports heavy components without deformation |

| Material | Virgin PP (100% recyclable) | 95% material recovery after 10+ cycles; UV-stabilized for outdoor storage |

Cost-Benefit: 30% lower part damage rates vs. single-use alternatives; 20% TCO reduction over 5-year lifecycle.

Agricultural Produce Handling

Designed for perishable goods transport, our boxes maintain freshness while withstanding harsh field-to-market logistics.

| Specification | Value | Benefit |

|---|---|---|

| Folding Durability | 10,000+ open/close cycles | Rapid nesting saves 40% storage space during return logistics |

| Moisture Resistance | Seamless sonic-welded seams | Prevents moisture ingress; extends shelf life by 15% |

| Load Capacity | 800kg dynamic / 2,500kg static | Handles stacked produce without crushing |

| Material | Food-grade PP | FDA/EC 10/2011 compliant; no chemical leaching |

Cost-Benefit: 25% reduction in spoilage costs; 50% lower total logistics cost vs. cardboard alternatives.

Construction Site Protection

Heavy-duty turnover boxes protect surfaces during high-traffic construction phases, eliminating costly repairs.

| Specification | Value | Benefit |

|---|---|---|

| Impact Resistance | 500kg point load capacity | Withstands forklifts, scaffolding, and equipment without cracking |

| UV Stability | 5-year outdoor exposure | No degradation under direct sunlight exposure |

| Modular Design | Interlocking edges | Creates seamless protective layers across large areas |

| Material | Reinforced HDPE | Resists oil, chemicals, and abrasion from construction debris |

Cost-Benefit: Eliminates $2,800+ per site in floor repair costs; 3x longer lifespan than plywood alternatives.

Beverage Industry Layer Pads

Precision-engineered pads for high-speed bottling lines, ensuring product integrity during transport.

| Specification | Value | Benefit |

|---|---|---|

| Die-Cutting Precision | ±0.3mm tolerance | Perfect fit for 500ml–2L bottles; prevents shifting during transit |

| Sonic Welding | Zero seam weakness | Withstands 1,800kg vertical stacking without deformation |

| Load Capacity | 1,200kg dynamic / 3,000kg static | Supports full pallets of glass bottles without failure |

| Material | FDA-compliant PP | Safe for direct food contact; recyclable post-use |

Cost-Benefit: 40% reduction in breakage rates; 35% lower packaging costs over 5-year lifecycle.

Proven ROI: EVERPLAST’s industrial turnover boxes deliver 12–18 month payback periods through reduced material waste, lower damage claims, and minimized replacement costs. All products are manufactured to ISO 9001 standards with full traceability from raw material to final inspection.

Ready to optimize your supply chain? Contact our B2B specialists for custom engineering solutions and volume pricing.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic Advantage in Plastic Turnover Box Sourcing

Factory-Direct Cost Efficiency

Eliminate 15–25% middleman markups through direct factory pricing

90,000 tons annual production capacity ensures uninterrupted supply chain resilience

6 high-speed extrusion lines guarantee consistent material density (0.90–0.91 g/cm³ PP/PE)

ISO 9001:2015 certified processes for zero-defect manufacturing

Rapid Delivery with Flexible Payment Terms

Standard lead time: 15–30 days (confirmed upon order)

30% deposit secures production slot; 70% balance due against shipment documents

Expedited options: 10–15 days for urgent orders (subject to capacity)

Global logistics: Qingdao port access for seamless FOB/CIF shipments

Engineering-Driven Technical Support

Precision die-cutting: ±0.2mm tolerance for flawless stacking in automated systems

Sonic welding: 100% hermetic seals eliminating dust/moisture ingress (no adhesive)

Load-tested to 1,200kg static / 800kg dynamic capacity for heavy industrial use

Industry-specific customization:

Automotive: Vibration-resistant crates for precision parts transport

Agriculture: UV-stabilized PP for outdoor produce storage (moisture-proof)

Construction: High-impact PE for tool logistics (scratch-resistant corners)

Logistics: Modular stacking with reinforced edges for 5,000+ reuse cycles

| Technical Specification | Everplast Standard | Industry Benchmark |

|---|---|---|

| Die-Cutting Tolerance | ±0.2mm | ±0.5mm |

| Folding Durability | 5,000+ cycles | 2,000–3,000 cycles |

| Static Load Capacity | 1,200kg | 800–1,000kg |

| Sealing Integrity | Sonic-welded hermetic seals | Adhesive-sealed joints |

| Material Options | Food-grade PP/PE (custom formulations) | Limited PP variants |

Ready to optimize your supply chain?

Contact our engineering team today for a custom sample and tailored quote:

📧 [email protected] | 📞 +86-532-8888-1234 | 🌐 www.everplast.com

📍 Export Processing Zone, West Coast, Qingdao, Shandong, China

Since 2009: Trusted by Fortune 500 manufacturers globally

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.