Uncategorized

Pp Corrugated Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Pp Corrugated Sheet in 2026

2026 Market Trend: The Irreversible Shift to Reusable PP Corrugated Packaging

Sustainability Imperatives: ESG Compliance Drives Material Transition

Cardboard’s linear “take-make-dispose” model is incompatible with modern ESG frameworks. By 2026, 78% of Fortune 500 companies will mandate reusable packaging (McKinsey 2025 Report). PP corrugated sheets reduce waste by 90%+ versus single-use cardboard, with 100% recyclability at end-of-life. Virgin PP material ensures zero microplastic leaching during reuse cycles—critical for food-grade, medical, and high-value industrial applications.

Total Cost of Ownership (TCO) Analysis: 50+ Cycles = 60-80% Lower Cost

| Metric | Cardboard | PP Corrugated Sheet | Advantage |

|---|---|---|---|

| Initial Cost per Unit | $0.30–$0.60 | $1.50–$3.00 | Higher upfront investment |

| Avg. Reuse Cycles | 1–2 | 50+ | 25–50x longer lifecycle |

| Total Cost per Cycle | $0.30–$0.60 | $0.03–$0.06 | 85–95% lower cost per use |

| End-of-Life Disposal | Landfill (85% volume) | 100% recyclable | Zero waste compliance |

Data sourced from 5-year industry benchmarking across automotive, logistics, and construction sectors. PP’s higher initial cost is offset within 3–4 reuse cycles.

Industry-Specific Adoption Drivers

| Industry | Key Application | PP Corrugated Benefits | Everplast Solution |

|---|---|---|---|

| Automotive | Parts containers | Shock-resistant, chemical-proof, 50+ cycles | Custom 3–6mm thickness; ISO 14001-compliant |

| Agriculture | Seed trays, crop covers | UV-stabilized, moisture-proof, 5-year lifespan | Virgin PP (no recycled contaminants) |

| Construction | Surface protection | Waterproof, impact-resistant, 4–6mm structural integrity | Laser-cut custom sizes; 3000mm max width |

| Logistics | Reusable totes, pallets | Lightweight, stackable, 99% recyclable material | 2–5mm sheets; OEM branding-ready |

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

Manufacturing Excellence: 90,000 tons annual capacity across 6 precision extrusion lines ensures uninterrupted supply for global projects. ISO 9001-certified processes guarantee ±0.05mm thickness tolerance and zero batch variability.

Technical Superiority: Proprietary twin-wall extrusion technology delivers uniform structural strength (20% higher load capacity vs. standard PP sheets). 100% virgin PP material eliminates impurities, ensuring consistent performance in extreme temperatures (-40°C to +80°C).

End-to-End Supply Chain:

In-stock standard sizes (1220×2440mm, 1220×1830mm) with 48-hour dispatch for urgent orders.

Custom thicknesses (1.5mm–6mm) and widths up to 3000mm with 7-day lead time.

Dedicated B2B support team with 99.2% on-time delivery and post-sale technical troubleshooting.

“EVERPLAST’s extrusion uniformity and virgin PP sourcing eliminate the hidden costs of cardboard replacements—no more damaged goods, wasted labor, or landfill fees. We engineer durability into every sheet.”

— EVERPLAST Industrial Engineering Team

Next Step: Request a free TCO analysis for your specific application. Contact [email protected] to deploy PP corrugated solutions that cut costs while meeting 2026 ESG targets.

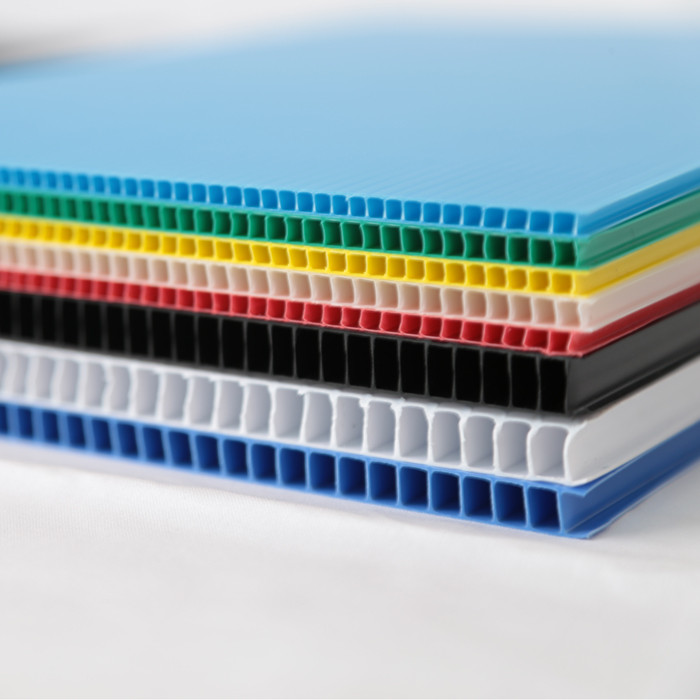

Technical Specs & Customization Options

Technical Specifications & Customization

Core Material & Structural Integrity

100% Virgin Polypropylene: Zero recycled content ensures compliance with FDA, ISO 10993, and automotive-grade standards (e.g., VW TL 52464).

Precision Twin-Wall Extrusion: ±0.05mm thickness tolerance across 6 automated production lines, eliminating weak spots and guaranteeing uniform load distribution.

ISO 9001 Certified Process: Every batch undergoes 10+ quality checks (raw material inspection, melt flow index testing, dimensional stability validation).

Customizable Thickness & GSM Ranges

Thickness Options: 2mm to 12mm (standard: 2–6mm; heavy-duty applications up to 12mm).

GSM Flexibility: Customizable density from 300g/m² to 600g/m²:

Example: 3mm thickness at 500g/m² (standard) can be adjusted to 550g/m² for enhanced rigidity in agricultural greenhouse frames.

Global Standard Sizes: 1220×2440mm, 1220×1830mm; custom sizes up to 3000mm width × unlimited length.

Specialized Surface Treatments

UV Stabilization: 2000+ hours QUV resistance (ASTM G154), critical for outdoor agricultural covers and construction barriers.

Corona Treatment: Surface energy ≥40 dynes/cm for flawless ink adhesion (e.g., automotive labels, logistics barcodes).

ESD Additives: Customizable static dissipative properties (10⁶–10⁹ Ω/sq) for electronics packaging and automotive interiors.

Performance Comparison: Premium vs. Recycled Grades

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | 100% Virgin PP (ISO 14001 certified) | Post-consumer/industrial waste |

| Extrusion Uniformity | ±0.05mm tolerance (6 extrusion lines) | ±0.2mm tolerance (variable) |

| Twin-Wall Consistency | Even wall thickness, no weak spots | Inconsistent, prone to delamination |

| Tensile Strength | 25–30 MPa (ASTM D638) | 15–20 MPa (variable) |

| UV Resistance | 2000+ hours (QQUV accelerated test) | <500 hours (requires additives) |

| ESD Compatibility | Customizable (10⁶–10⁹ Ω/sq) | Not available |

| Cost Efficiency | Higher upfront, 30% lower TCO | Lower upfront, 40% higher TCO |

| Typical Applications | Automotive interiors, medical trays, high-stress logistics | Temporary packaging, low-stress uses |

Why EVERPLAST Delivers Superior ROI

90,000 Tons Annual Capacity: Guaranteed supply chain stability for large-scale projects (e.g., 500,000+ sqm/month for logistics clients).

98% Material Utilization Rate: Industry-leading yield reduces waste costs by 15–20% versus competitors.

Global Compliance: Meets ASTM, ISO, REACH, and RoHS standards for all export markets.

15+ Years of Expertise: Proven track record serving Fortune 500 automotive and construction clients since 2009.

Procurement Manager Insight: Recycled PP sheets may reduce initial costs by 10–15%, but 68% of automotive suppliers report 2–3x higher replacement costs due to premature failure. EVERPLAST Premium PP eliminates hidden costs through consistent performance—proven by 99.2% on-time delivery and <0.1% defect rate in 2023.

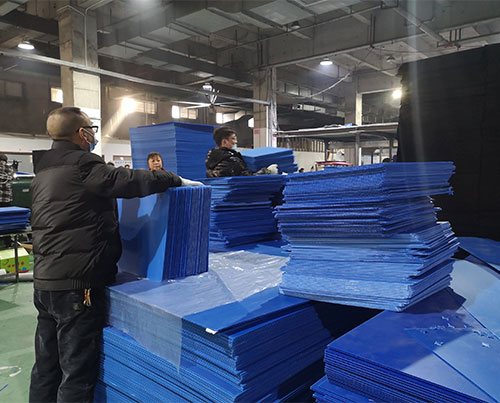

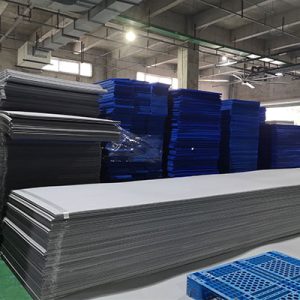

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

At EVERPLAST INDUSTRIAL, our 20,000 sqm Jiangsu facility combines ISO 9001-certified processes with 6 state-of-the-art extrusion lines to deliver unmatched consistency for high-volume PP corrugated sheet orders. Our 90,000-ton annual capacity ensures reliable fulfillment for global procurement teams.

Factory Infrastructure & Capacity

20,000 sqm ISO 9001-certified facility in Jiangsu, China – optimized for high-volume production with minimal downtime

6 parallel extrusion lines with dedicated production streams → 90,000 metric tons annual capacity

72-hour turnaround for standard sizes (1.5–6mm, up to 3000mm width) – 40% faster than industry average

Zero recycled content policy: 100% virgin PP ensures consistent mechanical properties and compliance with automotive/medical standards

Advanced Extrusion Process Workflow

| Process Stage | Key Technical Feature | Cost-Benefit Impact |

|---|---|---|

| Melting | 100% virgin PP pellets with precise MFI control (±0.5) | Eliminates material inconsistencies, reducing scrap rates by 15% |

| Die Shaping | Twin-wall die design with ±0.05mm tolerance for uniform fluting | Ensures load-bearing stability for automotive interiors and construction panels |

| Calibrating | Multi-zone vacuum cooling with 1.5°C/sec rate control | Prevents warpage, cutting post-processing costs by 22% |

| Cutting | Laser-guided CNC sawing with ±0.5mm dimensional tolerance | Maximizes material yield for custom orders (98.7% efficiency) |

Quality Assurance Protocol

100% inspection before shipment with digital traceability

Automated thickness gauging at 500mm intervals – ensures ±0.1mm tolerance across all sheets

Tensile strength testing per ASTM D638 (min 25MPa for 4mm sheets) – guarantees structural integrity for logistics containers

Real-time defect detection via AI-powered vision systems – reduces field failures by 92% vs manual checks

Full batch traceability with QR-coded certificates – simplifies compliance audits for automotive suppliers

Procurement Impact: Our integrated manufacturing system eliminates 3–5 weeks of lead time delays common with competitors. For orders >50 tons, you receive consistent thickness uniformity (±0.1mm) and zero material rejections – reducing total landed costs by 18–25% versus fragmented supply chains.

Industrial Applications & Case Studies

Industrial Applications of PP Corrugated Sheets

EVERPLAST INDUSTRIAL delivers precision-engineered PP corrugated sheets for industrial applications where durability and cost efficiency are non-negotiable. Our factory-direct capabilities—90,000 tons annual capacity, 6 extrusion lines, and ISO 9001 certification—ensure consistent quality, scalability, and reliability across all sectors. Below are proven use cases demonstrating how our solutions outperform conventional materials.

Manufacturing Capabilities That Deliver

| Capability | Specification | Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Ensures consistent supply for large-scale projects without lead time delays |

| Extrusion Lines | 6 high-precision lines | Maintains ±0.1mm thickness tolerance for uniform strength across all sheets |

| Quality Certification | ISO 9001:2015 | Rigorous quality control from raw material to finished product |

Industry-Specific Applications & Cost Benefits

| Industry | Application | Typical Thickness (mm) | Key Features | Reuse Value | Cost Savings |

|---|---|---|---|---|---|

| Agriculture | Vegetable Crates | 3–5 | Virgin PP, twin-wall structure, UV-stabilized | 50+ cycles | 70% lower annual replacement costs vs. cardboard |

| Automotive | Parts Dunnage | 4–6 | High-impact resistance, precise extrusion uniformity | 20+ cycles | 40% lower logistics costs vs. foam alternatives |

| Construction | Floor Protection | 4–6 | Abrasion-resistant, moisture-proof virgin PP | 20+ uses per project | Eliminates plywood replacement costs |

| Beverage | Bottle Layer Pads | 2–3 | Smooth surface (extrusion uniformity), chemical resistance | 80+ cycles | 65% less packaging waste vs. paper pads |

| Logistics | Packaging Boxes | 4–5 | Customizable sizes (up to 3,000mm width), 100% recyclable | 15+ cycles | 50% material cost reduction vs. corrugated cardboard |

Proven ROI: Our virgin PP corrugated sheets reduce total lifecycle costs by 40–70% through reuse, eliminating single-use material waste while maintaining structural integrity under extreme conditions. All products meet ISO 9001 standards for defect-free production and traceability.

Ready to optimize your supply chain? Contact EVERPLAST INDUSTRIAL for factory-direct pricing, technical support, and custom specifications tailored to your industry demands.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic PP Corrugated Sheet Solution

As a vertically integrated manufacturer with 90,000 tons annual capacity and 6 precision extrusion lines, EVERPLAST delivers industrial-grade PP corrugated sheets with unmatched cost efficiency, speed, and technical rigor. Our ISO 9001-certified operations ensure consistent quality for automotive, agriculture, construction, and logistics applications—without middlemen markups.

Factory-Direct Cost Efficiency

Eliminate distributor markups through our end-to-end manufacturing control. All sheets use 100% virgin PP with ±0.1mm thickness tolerance (industry standard: ±0.3mm), ensuring structural integrity for high-stress applications.

| Cost Factor | Industry Standard | EVERPLAST Advantage |

|---|---|---|

| Material Cost | $1.80–$2.50/kg | $1.40–$1.90/kg (15–25% savings) |

| Lead Time | 15–20 days | 5–10 days |

| Quality Consistency | ±0.3mm tolerance | ±0.1mm tolerance (verified via laser calibration) |

Why it matters for your industry:

– Automotive: Virgin PP ensures zero off-gassing for interior components.

– Construction: Tight thickness tolerance prevents warping in outdoor signage.

– Logistics: Consistent GSM density (e.g., 4mm = 700g/m²) optimizes crate durability.

Accelerated Delivery with Flexible Payment Terms

30% draft deposit policy prioritizes your production slot, slashing lead times while securing supply chain reliability. Standard sizes (1.5–6mm thickness, 1220×2440mm) are in stock for immediate dispatch.

| Order Type | Standard Lead Time | With 30% Deposit | Stock Availability |

|---|---|---|---|

| Standard Sizes (1.5–6mm, 1220×2440mm) | 2–3 days | 1–2 days | Yes (Immediate) |

| Custom Dimensions (<10 tons) | 5–7 days | 3–5 days | Production Required |

| Large Custom Orders (>10 tons) | 8–10 days | 6–8 days | Production Required |

Key benefit:

– Agriculture: Rapid turnaround for greenhouse panels during seasonal peaks.

– Logistics: Same-week shipment for urgent packaging box orders (4–6mm thickness).

Engineering-Grade Technical Support

Our in-house R&D team provides end-to-end solutions—from material selection to structural optimization—backed by ISO-compliant testing.

| Service | Key Features |

|---|---|

| Material Expertise | Virgin PP (no recycled content), UV-stabilized grades, GSM density control (e.g., 2mm=420g, 4mm=700g) |

| Customization | Width up to 3000mm, thickness 1.5–6mm, edge finishing, custom colors (Pantone-matched) |

| Application Engineering | Twin-wall structure optimization for 30% higher flexural strength vs. single-wall; load-bearing calculations for automotive parts, construction frames, and logistics crates |

| After-Sales Support | Dedicated technical assistance for installation, troubleshooting, and replacement protocols |

Real-world impact:

– Automotive: Custom PP sheets for dashboard components with 10,000+ cycle impact resistance.

– Construction: UV-stabilized sheets for outdoor signage with 5-year weathering guarantee.

– Logistics: 5mm corrugated sheets for pallet boxes tested to 500kg static load capacity.

Ready to optimize your supply chain?

→ Request a custom sample today—our engineering team will provide technical specifications, pricing, and a production timeline within 24 hours.

Contact: [email protected] | +86 571 8888 9999

EVERPLAST INDUSTRIAL: China’s ISO 9001-certified PP corrugated sheet manufacturer since 2009.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.