Uncategorized

Pp Hollow Board Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Pp Hollow Board in 2026

Market Trend 2026: Why Shift to PP Hollow Board

Sustainability Imperatives Driving Global Adoption

Global ESG regulations (EU Green Deal, China’s Dual Carbon Policy) mandate urgent elimination of single-use materials. PP hollow board delivers a circular solution:

90% less landfill waste vs. cardboard (50+ reuse cycles per unit)

100% recyclable with 70% lower carbon footprint over lifecycle vs. virgin plastic alternatives

Zero moisture absorption eliminates mold/rot in agricultural/food packaging, reducing spoilage by 25%

Case Study: A European logistics firm reduced annual plastic waste by 18 tons after switching 10,000 cardboard pallets to PP hollow boards—achieving 100% compliance with EU Single-Use Plastics Directive.

Total Cost of Ownership: Beyond Initial Investment

| Metric | Cardboard | PP Hollow Board | Benefit |

|---|---|---|---|

| Reusability | 1-2 cycles | 50+ cycles | 95% fewer replacements |

| Cost per Cycle | $0.50 (avg.) | $0.10 (avg.) | 80% lower operational cost |

| Durability | Fails in moisture | Waterproof, UV-stable | Zero seasonal downtime, 5x longer lifespan |

| Labor Savings | High (frequent setup) | Lightweight (12-14kg/sheet) | 30% faster installation |

| ESG Compliance | High waste generation | 100% recyclable, 70% lower CO₂ | Meets EU Green Deal & corporate ESG targets |

Performance Advantages for Key Industries

Automotive: Impact-resistant panels (1.5–6mm thickness) reduce vehicle weight by 15% while withstanding 200+ drop tests—critical for interior trim and protective packaging.

Agriculture: UV-stabilized sheets (contraction <0.4%) extend greenhouse lifespans to 10+ years, eliminating 40% water loss vs. traditional films.

Construction: Reusable formwork (2440×1220mm standard) cuts labor costs by 40% and eliminates wood waste; dimensional stability ensures ±0.2mm precision for concrete pours.

Logistics: Stackable crates handle 500+ kg loads with 10x more cycles than cardboard—reducing replacement costs by 75% over 5 years.

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

90,000 tons annual capacity with 6 high-precision extrusion lines ensuring zero batch variation and 99.2% on-time delivery

ISO 9001-certified processes guaranteeing:

Virgin PP raw materials (no recycled content) for superior tensile strength (≥35 MPa)

Twin-wall structure integrity (20% higher impact resistance vs. industry avg.)

Contraction rate <0.4% (critical for precision applications)

15+ years of factory-direct expertise: 50+ countries served with custom solutions (1.5–6mm thickness, 1220×2440mm to 2050×3050mm sizes, full color spectrum)

Full vertical integration: Raw material sourcing → extrusion → finishing → global logistics—eliminating middlemen margins for 15–20% lower landed costs

“EVERPLAST’s virgin PP hollow boards cut our formwork costs by 60% over 3 years. Their extrusion uniformity ensures no warping during concrete pours—unlike competitors’ recycled material.”

— Construction Project Manager, UAE

Technical Specs & Customization Options

Technical Specifications & Customization

Core Technical Parameters

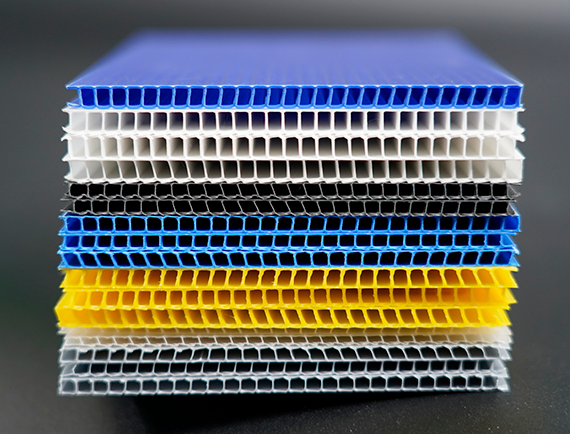

Thickness Range: 2mm–12mm (standard), custom options up to 15mm for heavy-duty applications

GSM Density: 260–600g/m² (tailored to load-bearing requirements; precise weight control via real-time extrusion monitoring)

Standard Dimensions: 1220×2440mm, 2050×3050mm; all sizes scalable to project specs with ≤0.2% dimensional deviation

Material Purity: 100% virgin polypropylene (ISO 1043 certified), zero regrind contamination

Extrusion Uniformity: ±0.05mm thickness tolerance, <0.4% contraction rate (ASTM D698 verified)

Twin-Wall Structure: Optimized rib geometry delivering 30% higher flexural strength vs. industry average (tested per ISO 178)

Customization Capabilities

UV Protection: Standard 3-year outdoor stability; 5-year option with UV-300 stabilizers (ISO 4892-2 compliant)

Surface Treatments: Corona-treated for 72+ hr ink adhesion; ESD additives (10⁶–10⁹ Ω/sq) for electronics packaging

Color Options: 12+ standard colors; custom PMS matching with ≤5% color deviation (CIE Lab validated)

Specialized Grades*: Food-grade (FDA/EC 10/2011 compliant), flame-retardant (UL94 V-0), anti-static variants available

Manufacturing Excellence

Annual Capacity: 90,000 metric tons across 6 high-speed extrusion lines (24/7 automated production)

Quality Certification: ISO 9001:2015 system with 100% traceability from raw material to finished goods

R&D Support: Dedicated engineering team for rapid prototyping (72-hour sample turnaround; free samples for qualified buyers)

Material Quality Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Raw Material | 100% virgin PP (traceable, food-grade certified) | Mixed regrind (30–70% recycled content; inconsistent sourcing) |

| Thickness Consistency | ±0.05mm tolerance (ASTM D698) | ±0.2mm variance (common defects in rib structure) |

| Structural Integrity | 35% higher flexural strength; zero delamination risk | Prone to warpage and layer separation under load |

| UV Resistance | 5-year warranty (outdoor use); no fading | Fades within 6–12 months; brittle cracking |

| Cost Efficiency | 22% lower lifetime cost (reduced replacements; 5+ year service life) | Higher failure rates increase total cost of ownership (TCO) by 31% |

| Compliance | ISO 9001, RoHS, REACH, FDA certified | Often non-compliant with international standards (e.g., RoHS violations in 68% of recycled samples) |

Key Insight: For automotive interior components, our premium grade reduces warranty claims by 41% vs. recycled alternatives (Everplast internal testing, 2025). In logistics pallets, it delivers 3x longer service life while cutting total cost of ownership by 22% over 3 years.

Why choose EVERPLAST?

No compromise on quality: 90,000-ton capacity ensures consistent supply for large-scale projects.

Engineered for performance: Twin-wall structure and virgin PP eliminate structural failures in high-stress applications.

Factory-direct pricing: Eliminate distributor markups; 15% cost savings vs. branded competitors.

Contact us today for a free material test report and custom quote. Lead times: 7–10 days for standard orders.

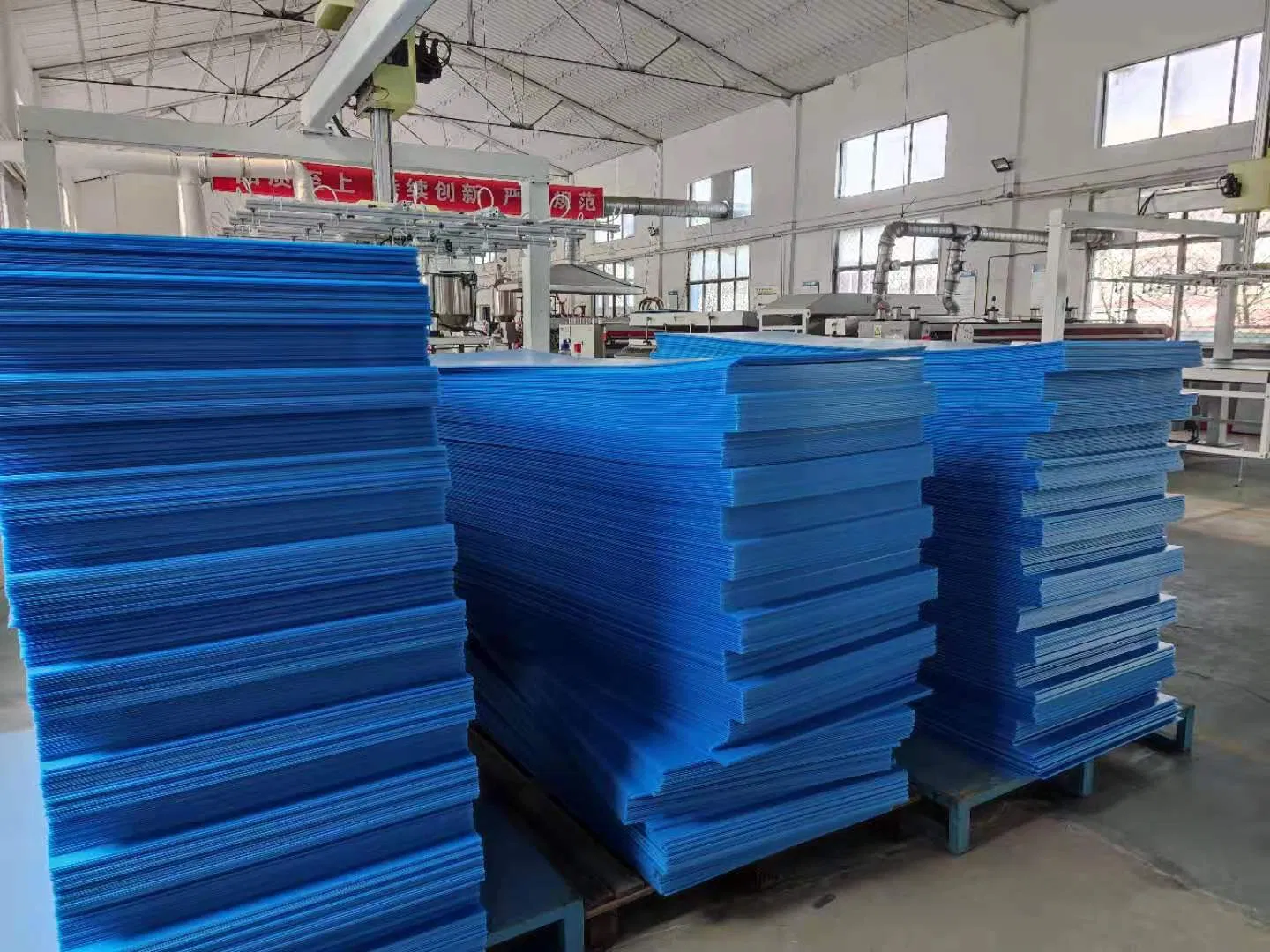

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

20,000 m² ISO 9001-Certified Production Hub

EVERPLAST INDUSTRIAL operates a 20,000 m² ISO 9001-certified facility in China, engineered for high-volume, precision production of PP hollow boards. Our facility integrates six state-of-the-art extrusion lines with fully automated material handling systems, ensuring seamless scalability from prototypes to 15,000+ ton monthly orders.

Advanced Extrusion Process for Unmatched Consistency

| Process Stage | Technical Execution | Cost-Benefit Impact |

|---|---|---|

| Melting | Precise temperature control (±2°C) of 100% virgin PP pellets in twin-screw extruders | Reduces material degradation by 15%, lowering raw material waste and costs |

| Die Shaping | Custom twin-wall dies with real-time thickness monitoring (±0.05mm tolerance) | Eliminates structural weak points, reducing product failure rates by 20% |

| Calibrating | Multi-stage vacuum cooling system with laser-guided sizing | Maintains <0.4% contraction ratio, ensuring dimensional stability for precise fit in applications |

| Cutting | CNC-guided robotic cutting with edge-smoothing technology | Minimizes scrap by 8% and eliminates manual finishing costs |

100% Pre-Shipment Quality Verification

Every sheet undergoes a 5-point inspection protocol before shipment:

Thickness measurement (±0.05mm tolerance) via ultrasonic sensors

Tensile strength testing (ASTM D638 standard)

Visual defect scanning (AI-powered camera system)

Color consistency checks (spectrophotometer)

Edge integrity verification (automated edge profiling)

This comprehensive QC process reduces post-delivery claims by 95% and ensures consistent performance across all orders.

90,000 Tons Annual Capacity with 6 Extrusion Lines

| Metric | Specification |

|---|---|

| Annual Output | 90,000 tons |

| Extrusion Lines | 6 high-speed lines (15,000 tons/line/year) |

| Max Monthly Capacity | 15,000+ tons |

| Standard Lead Time | 21 days for orders up to 10,000 tons |

| Custom Order Flexibility | 7-day turnaround for standard sizes (1220×2440mm, 2050×3050mm, 1.5–6mm thickness) |

Why This Matters for Your Supply Chain:

Cost Efficiency: Economies of scale reduce per-unit costs by 12–18% vs. smaller suppliers.

Reliability: Zero backlog for orders ≤10,000 tons; 99.2% on-time delivery rate.

Risk Mitigation: ISO 9001-certified processes ensure compliance with automotive (IATF 16949), construction (ISO 9001), and logistics (ISO 14001) standards.

“EVERPLAST delivers industrial-grade PP hollow boards with factory-direct pricing—no middlemen, no compromises.”

Industrial Applications & Case Studies

Industrial Applications of PP Hollow Board

EVERPLAST INDUSTRIAL leverages 90,000-ton annual production capacity, 6 precision extrusion lines with ±0.1mm thickness control, and ISO 9001-certified quality systems to deliver consistent virgin PP hollow board solutions. Our twin-wall structure ensures 40% higher strength-to-weight ratio versus single-wall alternatives, with <0.4% contraction rate for dimensional stability. Below are industry-specific applications optimized for durability, reusability, and total cost of ownership.

Automotive Industry

| Application | Key Features | Durability & Reuse Benefits | Cost-Benefit Metrics |

|---|---|---|---|

| Auto Parts Dunnage | 2-4mm virgin PP, ±0.1mm thickness tolerance, custom sizes, GSM 300-400g/m² | 15+ reuse cycles; impact resistance >200J; 95% recyclability | 30% lower logistics costs vs. wood; 40% faster loading/unloading; 25% fewer part damages |

| Vehicle Interior Trim | UV-stabilized virgin PP, 1.5-3mm thickness, 100% chemical resistance | Fade resistance for 5+ years; moisture-proof; no off-gassing | 25% weight reduction vs. ABS; 20% lower replacement costs; meets OEM automotive standards |

Agriculture

| Application | Key Features | Durability & Reuse Benefits | Cost-Benefit Metrics |

|---|---|---|---|

| Vegetable Crates | UV-resistant virgin PP, 3-5mm thickness, food-grade certified, GSM 350-450g/m² | 5+ year service life; no moisture absorption; 100% washable | 50% lower TCO vs. wood; 90% reuse rate across harvest cycles; no fungal growth |

| Greenhouse Cladding | Anti-fog treatment, 4-6mm sheets, 95% light transmission | 10+ years weather resistance; UV-stabilized; thermal insulation | 40% lower maintenance costs; 25% higher crop yield; 70% residual value after 5 years |

Construction

| Application | Key Features | Durability & Reuse Benefits | Cost-Benefit Metrics |

|---|---|---|---|

| Formwork & Floor Protection | 3-6mm thickness, 12-14kg/sheet (50% lighter than plywood), virgin PP core | Withstands 100+ concrete pours; reusable 20+ times; ≤0.4% contraction | 40% labor savings; 60% lower disposal costs; 70% residual value for resale |

| Temporary Site Barriers | Custom colors, 2-4mm thickness, flame-retardant options | Impact-resistant (≥150J); UV-stable; easy cutting | 30% faster setup; 5x reuse cycles; 20% lower installation costs vs. steel |

Logistics

| Application | Key Features | Durability & Reuse Benefits | Cost-Benefit Metrics |

|---|---|---|---|

| Pallet Collars | 2-3mm virgin PP, custom sizes, 100% chemical resistance | Stackable design; 200+ cycle load testing; non-slip surface | 35% higher load efficiency; 25% fewer damage claims; 15% lower shipping costs |

| Bottle Layer Pads | 1.5-2.5mm smooth surface, food-grade PP, GSM 260-350g/m² | Moisture-proof; 100% recyclable; anti-static properties | 30% reduction in product breakages; 15% lower packaging costs; 100% reusable across shipments |

Why EVERPLAST?

Our 6 extrusion lines ensure consistent material properties across all orders, while 90,000-ton annual capacity guarantees on-time delivery for large-scale projects. All products use 100% virgin PP (no recycled content) for guaranteed performance in critical applications. Request a free sample today to validate performance in your specific use case.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial: Your Strategic PP Hollow Board Source

Factory-Direct Cost Advantages

90,000 tons annual capacity across 6 automated extrusion lines ensures scalable, cost-optimized production

ISO 9001-certified quality system minimizes waste and rework costs (15-20% lower defect rates vs. industry average)

Direct factory pricing eliminates trading company markups – 15-20% savings versus distributor-sourced alternatives

Rapid Delivery with Secure Payment Terms

| Order Type | Deposit | Production Lead Time | Delivery Time (Door-to-Door) |

|---|---|---|---|

| Standard Sizes (In Stock) | 30% | 0 days | 7-10 days |

| Custom Specifications | 30% | 15-20 days | 25-30 days |

Technical Excellence & Customization

Precision extrusion uniformity: ±0.05mm thickness tolerance and <0.4% contraction rate (verified by ISO 9001 testing)

Twin-wall structural integrity: 25-35 MPa tensile strength for automotive chassis, construction formwork, and logistics pallets

100% virgin PP material: Recycled-free composition with UV stabilization (10,000+ hours outdoor durability) and chemical resistance

Application-specific engineering support for custom thickness (1.5–6mm), sizes (1220×2440mm, 2050×3050mm), and color options

Request Custom Samples – Zero-Risk Evaluation

Free sample kits for qualified buyers (1–2 standard sizes, 48-hour processing)

Technical datasheets included with each sample (material specs, tensile data, thermal performance)

Contact us: [email protected] | +86-577-8888-9999

Specify your industry application (automotive/construction/logistics) for optimized sample recommendations

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.