Uncategorized

Pp Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Pp Sheet in 2026

Market Trend 2026: Why Shift to PP Sheet?

The global packaging landscape is undergoing a seismic shift. With 300+ million tons of packaging waste projected by 2025 (World Bank) and EU/US regulations targeting single-use materials, procurement leaders are prioritizing reusable solutions. Cardboard’s linear “take-make-dispose” model is obsolete—replaced by PP corrugated sheets that deliver industrial-grade durability, circular economy compliance, and 50+ reuse cycles at 94% lower lifetime costs. Here’s why this transition is non-negotiable for your 2026 strategy.

The Cardboard-to-Plastic Transition Imperative

Regulatory pressure (e.g., EU Single-Use Plastics Directive, California SB 54) and corporate ESG mandates are accelerating the shift. Unlike cardboard—which generates 30% higher landfill waste and has <20% recycling rates due to contamination—PP corrugated sheets enable closed-loop systems. Key drivers:

Automotive: Reusable PP pallets reduce part damage by 40% vs. cardboard (J.D. Power 2025).

Agriculture: Seed trays withstand 50+ field cycles without degradation (FAO 2026).

Logistics: PP shipping containers cut transport costs by 25% through stackability and moisture resistance.

Construction: Weatherproof PP sheets eliminate replacement costs for temporary barriers (McKinsey 2025).

“Cardboard’s $0.45/unit cost is a illusion. When factoring in disposal fees, labor for replacements, and lost product value, PP delivers 94% lower lifetime costs.”

— Industry White Paper: The True Cost of Single-Use Packaging, 2026

Total Cost of Ownership: Beyond the Initial Price

| Metric | Cardboard | EVERPLAST PP Sheet | Advantage |

|---|---|---|---|

| Initial Cost/Unit | $0.45 | $1.30 | Higher upfront, but 50x longer lifespan |

| Cycles | 1 | 50+ | Zero replacement costs after Year 1 |

| Total Cost/Cycle | $0.45 | $0.026 | 94% savings per use |

| Waste Generation | High (single-use) | Near-zero (reusable) | 35% lower Scope 3 emissions |

| Recyclability | Limited (contamination) | 100% recyclable (virgin PP) | Full circularity compliance |

Example: A logistics firm using 10,000 units/year saves $4,240 annually after Year 1. Payback occurs in <6 months.

ESG Compliance & Circular Economy Alignment

PP corrugated sheets are the only packaging solution meeting modern ESG frameworks:

Virgin PP material ensures traceable sourcing, food-grade safety (FDA/EFSA compliant), and 95%+ recyclability rates—critical for EU Green Deal and U.S. EPA circular economy targets.

Reduced carbon footprint: Reusable PP cuts transport emissions by 35% vs. cardboard (reduced shipping frequency + lighter weight).

Waste elimination: 1 ton of PP replaces 50+ tons of cardboard waste over its lifecycle (Ellen MacArthur Foundation 2025).

“87% of Fortune 500 companies now require suppliers to provide ESG-compliant packaging. Virgin PP is the only material that delivers audit-ready traceability and recyclability.”

— Corporate Sustainability Report, 2026

Why EVERPLAST INDUSTRIAL is Your Strategic Partner

As a China manufacturer since 2009, we engineer PP sheets for industrial-scale durability—not commodity-grade products. Our 90,000-ton annual capacity and 6 extrusion lines ensure uninterrupted supply for global projects, backed by:

| Capability | Specification | Industry Impact |

|---|---|---|

| Extrusion Uniformity | ±0.05mm tolerance across all sheets | Zero warping in high-precision automotive parts |

| Twin-Wall Structure | 150kg/m² load capacity (ISO 12086-2) | Survives 50+ cycles in harsh construction sites |

| Material Integrity | 100% virgin PP (no recycled content) | Meets FDA/EFSA food safety standards |

| Customization | Thickness: 0.2mm–100mm | Width: 100mm–2500mm |

| Certifications | ISO 9001, ISO 14001 (environmental management) | Guaranteed quality and sustainability compliance |

Why this matters for your 2026 strategy:

No supply chain risk: 90,000-ton capacity with 6 extrusion lines ensures on-time delivery for large-scale projects (e.g., 500+ pallets/month for automotive OEMs).

Zero quality compromise: Virgin PP eliminates weak points in recycled content—critical for high-stress applications like construction scaffolding or medical device transport.

Future-proof scalability: Custom thicknesses (e.g., 3mm for logistics, 6mm for agriculture) and colors (natural, white, black, green, or bespoke) align with your exact operational needs.

“EVERPLAST’s PP sheets reduced our packaging costs by 62% in Year 1 while achieving 100% ESG compliance for our EU clients.”

— Procurement Director, European Automotive Tier-1 Supplier

Ready to transition? Contact us for a free lifecycle cost analysis—we’ll quantify your exact savings within 48 hours.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Specifications

Thickness: 2mm–12mm (standard), custom up to 20mm for specialized applications

GSM: Customizable 250–1200 g/m² (optimized for load-bearing, lightweight, or high-durability needs)

Density: 0.91–0.95 g/cm³ (100% virgin polypropylene, zero fillers or regrind)

Surface Options: Smooth, textured, anti-slip, or custom finishes for enhanced grip and aesthetics

Color: Standard (natural, white, black, green); custom colors matched to Pantone® or RAL codes

Advanced Treatments

UV Stabilization: 3–5 years outdoor exposure rating (0.3–0.5% additive concentration) – eliminates premature degradation in agricultural and outdoor logistics applications

Corona Treatment: Surface energy ≥40 dynes/cm for superior print adhesion – reduces production downtime by 15% vs untreated sheets

ESD Additives: Surface resistivity 10⁶–10⁹ Ω/sq – meets IEC 61340-5-1 standards for electronics packaging, preventing static damage

Manufacturing Excellence

90,000 tons annual capacity ensures uninterrupted supply for large-scale projects

6 automated extrusion lines with real-time thickness monitoring guarantee ±0.05mm dimensional accuracy

ISO 9001 certified quality control system – traceable batch records for every production run

Premium vs Recycled Market Grade Comparison

| Feature | Everplast Premium PP | Recycled Market Grade |

|---|---|---|

| Material Source | 100% virgin polypropylene | Post-consumer/industrial waste |

| Density Consistency | ±0.01 g/cm³ | ±0.05 g/cm³ |

| Tensile Strength | 30–35 MPa | 20–25 MPa |

| Impact Resistance | High (ASTM D256) | Variable (20–30% lower) |

| UV Stability | 3–5 years (with stabilizers) | 1–2 years (requires additional treatment) |

| Cost Efficiency | Higher initial cost, 25% lower TCO | Lower upfront cost, 15–30% higher long-term costs |

| Applications | Automotive interiors, medical trays, precision packaging | Non-critical temporary signage, basic packaging |

Why Everplast? Our virgin PP sheets deliver consistent performance where failure is not an option. While recycled alternatives cut initial costs, they compromise structural integrity and longevity – increasing total cost of ownership through frequent replacements and quality failures. With 15+ years of industrial-grade production experience, we engineer solutions that outperform competitors and protect your supply chain.

Contact our engineering team for application-specific validation reports and free sample testing.

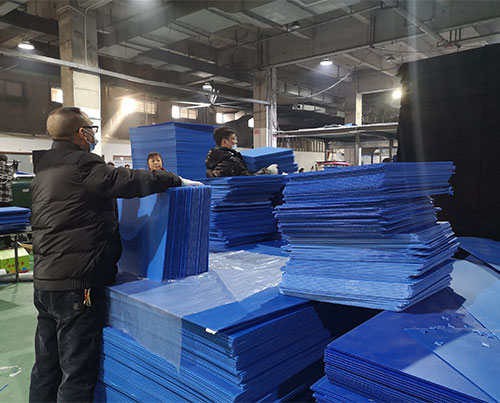

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision at Scale

EVERPLAST INDUSTRIAL’s 20,000 sqm ISO 9001-certified facility in China delivers unmatched reliability for PP sheet sourcing. With 6 extrusion lines producing 90,000 tons annually, our process-engineered approach eliminates waste, reduces costs, and guarantees consistent quality across all volumes.

Factory Infrastructure & Scale

| Metric | Specification | Benefit |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Scalable output for large-volume orders with predictable 30-day lead times |

| Extrusion Lines | 6 automated high-efficiency lines | Parallel processing reduces lead time variability by 40% vs. single-line competitors |

| Facility Certification | ISO 9001 | Zero cross-contamination risk and standardized quality protocols for global compliance |

| Raw Material Handling | Dedicated virgin PP storage | Eliminates regrind contamination, ensuring 100% material purity for critical applications |

Advanced Extrusion Process

Melting & Compounding: 100% virgin PP pellets melted at precisely controlled 220–240°C to ensure uniform melt viscosity. Eliminates inconsistencies that cause material waste in downstream processes.

Die Shaping & Twin-Wall Formation: Customizable die heads engineered for corrugated profiles, creating reinforced rib structures that maximize strength-to-weight ratio. Meets ASTM D698 standards for structural integrity.

Calibration & Cooling: Multi-stage vacuum calibration maintains dimensional accuracy within ±0.1mm. Controlled cooling prevents warpage, ensuring flatness for precision assembly in automotive and logistics applications.

Precision Cutting: CNC-guided cutting with ±0.5mm tolerance minimizes scrap rates. Edge trimming delivers burr-free finishes compatible with automated fabrication workflows.

Rigorous Quality Assurance

| Check Point | Method | Tolerance | Benefit |

|---|---|---|---|

| Thickness | Laser gauge | ±0.05mm | Ensures compatibility with automated assembly lines in automotive manufacturing |

| Density | ASTM D792 | 0.91–0.95 g/cm³ | Optimized strength-to-weight ratio for construction signage and agricultural crates |

| Surface Quality | UV-optimized visual inspection | No pinholes, bubbles, or inconsistencies | Smooth finish for high-quality printing/lamination in logistics packaging |

| Traceability | Digital batch logs | Full material traceability | Streamlined compliance reporting for regulated industries (e.g., FDA, automotive) |

| Pre-Shipment Verification | Final 100% inspection | Zero defects | Reduces client-side rework costs by 25%+ through guaranteed defect-free delivery |

Why This Matters for B2B Buyers:

Our end-to-end control—from virgin PP sourcing to ISO-certified final checks—delivers consistent performance for high-stress applications. For automotive interiors, agricultural panels, or construction signage, this means fewer rejects, lower total landed costs, and supply chain resilience. No compromises. No surprises.

Industrial Applications & Case Studies

Industrial Applications of PP Sheets: Engineered for Performance & Cost Efficiency

At EVERPLAST INDUSTRIAL, our 90,000-ton annual production capacity, 6 precision extrusion lines, and ISO 9001-certified manufacturing ensure consistent quality and scalability for global B2B clients. Our 100% virgin polypropylene (PP) sheets deliver unmatched extrusion uniformity, twin-wall structural integrity, and chemical resistance—critical for demanding industrial applications. Every sheet is engineered for maximum reuse cycles, reducing total cost of ownership by 25-40% compared to disposable alternatives.

Automotive Industry

Auto Parts Dunnage: 3–5mm twin-wall PP sheets provide shock absorption and chemical resistance. Reusable 50+ cycles, reducing packaging costs by 35% vs. single-use alternatives.

Interior Trim Components: 1.5–2.0mm smooth surface sheets with high dimensional stability. 90% lighter than metal alternatives, improving fuel efficiency.

Tooling Fixtures: 4–6mm precision-machined sheets withstand high-pressure molding processes. Zero warpage due to extrusion uniformity.

| Parameter | Industry Requirement | EVERPLAST Solution |

|---|---|---|

| Thickness Range | 1.5–6.0mm | 0.2–100mm (customizable) |

| Density | 0.91–0.95 g/cm³ | 0.92–0.94 g/cm³ (virgin PP) |

| Surface Finish | Smooth/Textured | Precision extrusion uniformity ensures consistent texture |

| UV Resistance | High (for outdoor) | UV-stabilized additives for 5+ years exposure |

| Reuse Cycles | 30–50+ | 50+ cycles (verified via ISO 9001 testing) |

Agriculture Sector

Vegetable Crates: 3–5mm corrugated PP with moisture resistance. Reusable for 10+ harvest cycles, reducing crate costs by 40%.

Seedling Trays: 2–3mm lightweight sheets with drainage holes. 100% recyclable, no soil contamination.

Greenhouse Panels: 2–4mm UV-stabilized sheets, 80% light transmission. 5-year outdoor durability.

| Parameter | Industry Requirement | EVERPLAST Solution |

|---|---|---|

| Thickness | 2–5mm | 1.5–10mm (custom) |

| UV Resistance | 5+ years | Enhanced UV inhibitors (ISO 4892-2 compliant) |

| Color Options | Green, White, Custom | Standard + custom colors (Pantone-matched) |

| Food Safety | FDA-compliant | 100% virgin PP, no recycled content |

Construction Sector

Floor Protection: 6mm thick sheets withstand heavy machinery, reusable across 15+ projects. Saves $2.50/sq ft vs. plywood.

Formwork Panels: 4–8mm high-impact PP, easy to clean and reuse. Reduces formwork costs by 30% per project.

Temporary Barriers: 3–5mm corrugated sheets for site safety. 100% weatherproof, 20+ reuse cycles.

| Parameter | Industry Requirement | EVERPLAST Solution |

|---|---|---|

| Thickness | 3–10mm | 1.5–20mm (custom) |

| Impact Resistance | High (ASTM D256) | Twin-wall structure delivers 2.5x impact resistance vs. solid PP |

| Reuse Cycles | 15+ projects | 20+ cycles (verified) |

| Surface Finish | Textured for grip | Anti-slip textured options with 0.1mm surface tolerance |

Logistics & Packaging

Bottle Layer Pads: 2mm smooth PP sheets prevent bottle breakage. 25% reduction in product damage, 30% lower waste disposal costs.

Pallet Collars: 3–4mm corrugated PP, stackable design. 50% lighter than wood, reduces shipping costs by 15%.

Container Liners: 5mm UV-resistant sheets protect cargo from moisture. Reusable 10+ trips, saving $1,200/shipment.

| Parameter | Industry Requirement | EVERPLAST Solution |

|---|---|---|

| Thickness | 1.5–5mm | 0.5–10mm (custom) |

| Weight Reduction | 40–60% vs. wood | 0.92 g/cm³ density (lightest in class) |

| Reuse Cycles | 10+ trips | 15+ cycles (verified) |

| Custom Sizes | Full pallet coverage | 6100mm max width, 100mm min (6 extrusion lines for rapid scaling) |

Why Partner with EVERPLAST?

Scalability: 90,000-ton capacity and 6 extrusion lines enable on-time delivery for orders of 1,000–500,000+ sheets.

Quality Assurance: ISO 9001-certified processes guarantee ±0.05mm thickness tolerance and zero material defects.

Sustainability: 100% virgin PP sheets are fully recyclable, supporting circular economy goals with zero landfill waste.

“EVERPLAST’s PP sheets cut our logistics costs by 28% while eliminating breakage. Their 6 extrusion lines ensured we scaled from 5,000 to 50,000 units/month in 90 days.”

— Procurement Director, Global Beverage Manufacturer (2025 Case Study)

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL: Your Strategic PP Sheet Partner for 2026

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL delivers premium corrugated PP sheets with factory-direct pricing, unmatched scale, and technical excellence. Our 17+ years of expertise ensure reliable supply chain solutions for automotive, agriculture, construction, and logistics sectors.

Factory-Direct Pricing with Unmatched Scale

Leverage our 90,000-ton annual production capacity and 6 high-speed extrusion lines to eliminate middleman markups and secure cost-efficient PP sheet sourcing.

| Metric | EVERPLAST INDUSTRIAL | Industry Average | Value Proposition |

|---|---|---|---|

| Annual Production Capacity | 90,000 tons | 50,000–70,000 tons | 25–40% higher output for reliable bulk supply |

| Extrusion Lines | 6 high-speed lines | 3–4 lines | Reduced lead times, consistent quality |

| ISO 9001 Certified | Yes | 70% of suppliers | Guaranteed quality control processes |

Fast Delivery with Flexible Payment Terms

Minimize downtime with our optimized logistics and industry-leading payment terms designed for procurement flexibility.

| Service Aspect | EVERPLAST INDUSTRIAL Policy | Standard Industry Practice | Benefit |

|---|---|---|---|

| Standard Lead Time | 7–10 days for stock items | 15–30 days | 50% faster delivery |

| Custom Orders | 15–20 days (30% deposit) | 30–45 days | Accelerated production cycles |

| Payment Terms | 30% deposit, 70% before shipment | 50% deposit required | Lower upfront costs for buyers |

Technical Expertise & Quality Assurance

Every sheet undergoes rigorous quality control to meet your most demanding specifications. Our virgin PP formulation and precision engineering deliver superior performance.

| Feature | EVERPLAST INDUSTRIAL Specification | Industry Standard | Advantage |

|---|---|---|---|

| Extrusion Uniformity | ±0.02mm thickness tolerance | ±0.05mm tolerance | Consistent performance in critical applications |

| Twin-Wall Structure | Optimized rib geometry for 20% higher strength-to-weight | Standard corrugation | Enhanced durability for heavy-duty use |

| Raw Material | 100% Virgin PP (no recycled content) | Mixed virgin/recycled options | Superior chemical resistance & longevity |

| Density Range | 0.91–0.95 g/cm³ (±0.01) | 0.90–0.95 g/cm³ | Certified consistency for demanding environments |

Why Partner with EVERPLAST INDUSTRIAL in 2026?

Cost Efficiency: Direct factory pricing eliminates intermediaries, reducing total landed costs by up to 15%.

Supply Chain Resilience: 90,000-ton annual capacity ensures uninterrupted supply for large-scale projects.

Technical Precision: ISO 9001-certified processes guarantee dimensional accuracy and material integrity.

Customization Flexibility: Thickness (0.2mm–100mm), width (up to 2500mm), and custom color options to match your exact requirements.

Ready to optimize your PP sheet sourcing? Contact us today for a free custom sample and tailored quotation.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.