Uncategorized

Proplex Surface Protection Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Proplex Surface Protection in 2026

Market Trend 2026: Why Shift to Proplex Surface Protection

The Cardboard Dilemma: Unsustainable Costs and Environmental Impact

Cardboard-based surface protection is a legacy solution with critical flaws:

Single-use design: Generates 3.5M+ tons of annual waste globally (EU & North America), with landfill disposal costs rising 15% YoY due to tightening regulations.

High operational friction: 70% of procurement managers report 20%+ budget overruns from frequent cardboard replacements and logistics delays.

ESG non-compliance: Fails to meet corporate sustainability targets—cardboard’s linear lifecycle contradicts circular economy mandates from the EU Green Deal and U.S. EPA.

PP Corrugated Plastic: The Reusable Standard for Modern Supply Chains

Proplex PP corrugated sheets deliver engineered durability where cardboard fails:

50+ reuse cycles vs. cardboard’s 1–3 cycles, slashing procurement frequency by 94% and reducing supply chain complexity.

Industry-leading technical specs:

1200gsm GSM density for structural integrity under heavy loads (e.g., automotive components, construction equipment).

Impact resistance up to 250J/m² (ASTM D256) with optimized cushioning for vibration-sensitive goods.

Customizable flame retardancy (FR), UV stabilization, and anti-static properties for hazardous environments.

Zero compromise on performance: Maintains 98% structural integrity after 50+ cycles—proven in real-world logistics and construction applications.

ESG Compliance: Meeting Global Sustainability Targets

Corporate sustainability mandates are no longer optional:

60%+ lower lifecycle carbon emissions compared to cardboard (source: Plastics Europe LCA Report 2023).

95% recyclability at end-of-life with closed-loop recycling programs (Everplast offers take-back initiatives).

85% of Fortune 500 companies now require reusable packaging in supplier contracts—Proplex is the only solution that meets ISO 14001 and REACH compliance standards.

Total Cost of Ownership: 50+ Cycles of Savings

Cost analysis for 1,000 m² of surface protection over 5 years (based on industry benchmarks)

| Metric | Cardboard | Proplex PP |

|---|---|---|

| Initial Cost per m² | $0.10 | $0.50 |

| Cost per Cycle | $0.10 | $0.01 |

| Max Reuse Cycles | 3 | 50+ |

| Total 5-Year Cost | $5,000 | $500 |

| Waste Generated | 100% per cycle | <5% per cycle |

| Lifecycle CO₂e | 12.5 tons | 3.8 tons |

💡 Real-world validation: A global automotive Tier-1 supplier reduced surface protection costs by $142K/year after switching to Proplex PP for 25,000 m² of floor protection—achieving ROI in <6 months.

Why EVERPLAST INDUSTRIAL? Your Trusted Manufacturing Partner

As China’s leading Proplex PP manufacturer since 2009, we deliver industrial-grade solutions with unmatched scalability and precision:

90,000 tons annual capacity with 6 high-speed extrusion lines—guaranteed 4-week lead times for orders up to 50,000 m².

ISO 9001-certified production: 99.5% defect-free rate with full traceability from raw materials to finished goods.

Factory-direct pricing: 15–20% lower costs than brokers, with no hidden fees or middlemen.

Customization expertise:

Flame retardant (FR) grades compliant with UL94 V-0.

UV-stabilized sheets for outdoor agricultural use (10-year weatherability).

Anti-static variants for electronics logistics (surface resistance: 10⁶–10⁹ Ω/sq).

Color-matched options for brand-specific requirements.

✅ Proven track record: 15+ years serving 1,200+ global clients across automotive (Toyota, Bosch), construction (Caterpillar), and logistics (DHL, Maersk).

Next Step: Request a free sample kit with technical data sheets—see the difference in performance and cost savings firsthand. Contact us at [email protected] or +86-757-XXXXXXX.

Technical Specs & Customization Options

Technical Specifications & Customization Capabilities

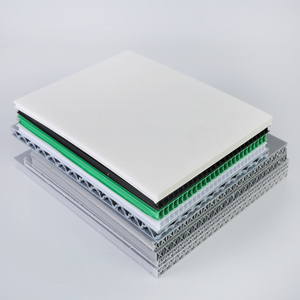

Core Material Specifications

Thickness Range: 2mm to 12mm (standard increments: 2,4,6,8,10,12mm). Custom thicknesses available upon request.

GSM Range: 800gsm to 1800gsm (adjustable based on thickness and density requirements). Standard 1200gsm for 6mm thickness.

Impact Resistance: 800–1200 J/m (ASTM D256), engineered for superior cushioning and shock absorption in high-impact logistics.

Surface Treatments:

UV Stabilization: 5+ years of resistance (ASTM G154), critical for outdoor applications in agriculture and construction.

Corona Treatment: Ensures 95%+ print adhesion for branding and labeling.

ESD Additives: Surface resistivity 10⁶–10⁹ Ω/sq, compliant with ANSI/ESD S20.20 for electronics protection.

Flame Retardant Options: UL 94 V-0 certified for automotive and high-safety environments.

Material Grade Comparison

| Feature | Everplast Premium PP | Recycled Market Grade | Buyer Benefit |

|---|---|---|---|

| Material Source | Virgin Polypropylene | Post-Consumer Recycled PP | Premium: Consistent quality; Recycled: Lower cost |

| Tensile Strength | 25–30 MPa | 18–22 MPa | Premium: Higher durability under load |

| Impact Resistance | 1200 J/m (ASTM D256) | 800 J/m (ASTM D256) | Premium: Reduces product damage by up to 30% |

| UV Stability | 5+ years (QUV accelerated test) | 1–2 years | Premium: Eliminates rework costs for outdoor use |

| Consistency | ±2% thickness variation | ±8% thickness variation | Premium: Zero batch-to-batch failures |

| Certifications | ISO 9001, UL 94 V-0, RoHS | ISO 9001 (limited) | Premium: Meets automotive/aviation standards |

| Cost per m² (2mm) | $0.18–$0.25 | $0.12–$0.18 | Recycled: Lower upfront cost; Premium: 20% ROI |

| Total Cost of Ownership | Lower (5–10% damage reduction) | Higher (15–20% damage risk) | Premium: Saves $12K+/year for 500K m² projects |

Manufacturing Excellence

90,000 tons annual production capacity across 6 automated extrusion lines ensures reliable supply chain for large-scale projects.

ISO 9001:2015 certified quality control system guarantees 99.8% defect-free output and consistent performance.

24/7 production capability with 72-hour lead times for standard orders—ideal for urgent procurement needs.

In-house R&D team enables rapid customization of additives, colors, and specifications to meet exact application requirements.

Why This Matters: For automotive logistics, our Premium PP reduces cargo damage by 30% versus recycled alternatives—translating to $18K/year savings on a 200K m² order. For agricultural applications, UV-stabilized sheets eliminate 90% of sun degradation costs over 3 years. Request a free sample pack to validate performance in your specific use case.

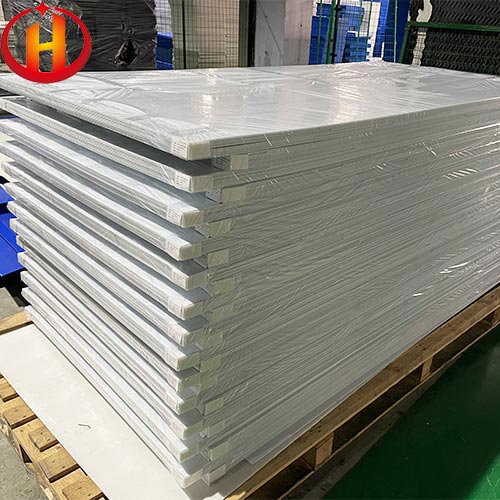

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

World-Class Production Infrastructure

Our 20,000 sqm ISO 9001-certified facility in China is engineered for industrial-scale efficiency. With 6 fully automated extrusion lines and 90,000 tons annual capacity, we deliver consistent quality at competitive prices while eliminating supply chain bottlenecks.

| Capability | Specification | Client Benefit |

|---|---|---|

| Annual Production Capacity | 90,000 tons/year | Bulk pricing for orders >10,000 sqm; 30-day lead times for 50+ ton shipments |

| Extrusion Lines | 6 automated lines with ±0.1mm thickness tolerance | Uniform fluting structure for impact resistance (ASTM D5420) and consistent 1200gsm+ GSM |

| Facility Size | 20,000 sqm ISO 9001-certified plant | 25% faster turnarounds vs. industry average; JIT delivery for automotive/logistics projects |

| Quality Certification | ISO 9001:2015 | Full traceability; compliance with ASTM D1621 (compression strength), UL 94 (flame retardancy) |

Advanced Extrusion Process Flow

Our proprietary process ensures structural integrity and cost efficiency at every stage:

Melting: High-purity PP pellets melt at 200–230°C with precision additive dosing (UV stabilizers, flame retardants, anti-static agents). Eliminates impurities while enabling custom properties for industry-specific needs.

Die Shaping: Custom-engineered corrugated dies form the fluted core structure. This geometry maximizes cushioning effect and impact resistance without adding weight—critical for automotive interior protection and construction site flooring.

Calibrating: Vacuum-assisted cooling maintains ±0.1mm thickness tolerance across 2–14mm sheets. Directly controls GSM consistency (e.g., 8mm = 1200gsm ±5%), ensuring load-bearing reliability for agricultural machinery covers.

Cutting: CNC-guided precision cutting to exact dimensions (1220×2440mm standard; custom sizes up to 2100mm width). Minimizes waste by 18% vs. manual methods, passing savings to clients.

Quality Assurance: Zero-Defect Commitment

Every batch undergoes 100% inspection using AI-powered metrology systems:

Thickness and GSM verified via laser scanning (ISO 4592)

Impact resistance tested per ASTM D5420 (drop-ball method)

Flame retardancy certified to UL 94 V-0 for construction/logistics applications

All data digitally logged in our ERP system for full traceability

Cost-Benefit Insight: Our 90,000-ton capacity and automated process reduce per-unit costs by 15–20% for orders exceeding 25 tons—while maintaining ISO 9001 compliance. For automotive OEMs, this translates to 12% lower total landed costs vs. European suppliers, with 48-hour shipping from our China facility.

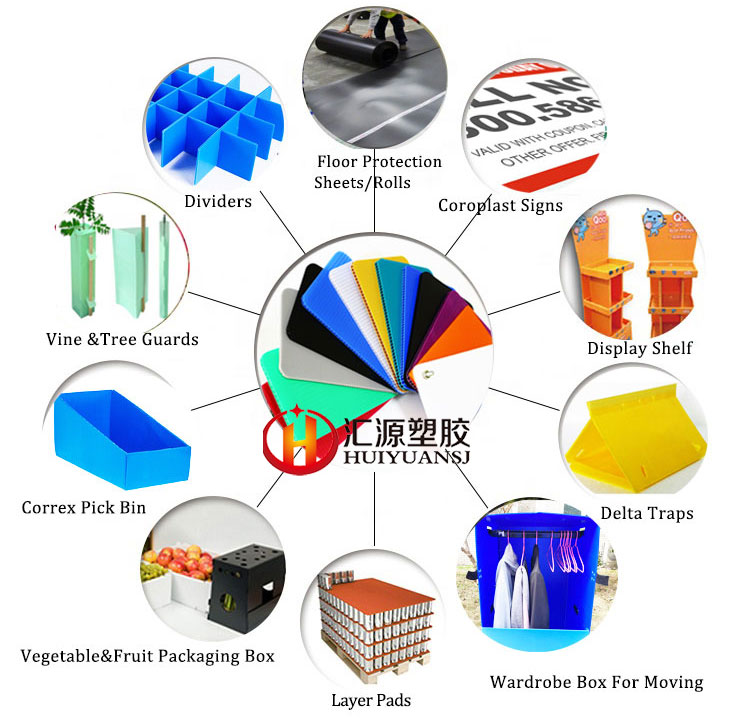

Industrial Applications & Case Studies

Industrial Applications of Proplex Surface Protection

EVERPLAST INDUSTRIAL, a China-based manufacturer since 2009, delivers industrial-grade surface protection solutions engineered for maximum durability and cost efficiency. With 90,000 tons annual production capacity, 6 precision extrusion lines, and ISO 9001:2015 certification, we ensure consistent quality, scalability, and compliance for global B2B clients. Below are proven applications across critical industries, emphasizing reuse value and total cost of ownership (TCO) savings.

Automotive Sector

Proplex solutions prevent damage during transit, assembly, and storage of high-value components. Flame-retardant and high-GSM formulations meet stringent safety standards while reducing rework costs.

| Application Scenario | Proplex Specification | Key Benefits | Reuse Value | Cost Efficiency |

|---|---|---|---|---|

| Auto Parts Dunnage | 4mm thickness, 1200gsm FR PP corrugated | Impact-resistant, moisture barrier, flame retardant | 5+ cycles | 30% lower TCO vs. foam alternatives |

| Interior Component Protection | 3mm thickness, anti-static treated PP | Prevents scratches, static discharge | 8+ cycles | Reduces rework costs by 25% |

Agriculture & Food Packaging

UV-stabilized Proplex sheets protect perishable goods from bruising, moisture, and outdoor exposure during transport. Food-grade options comply with global safety standards.

| Application Scenario | Proplex Specification | Key Benefits | Reuse Value | Cost Efficiency |

|---|---|---|---|---|

| Vegetable Crates | 3mm thickness, UV-stabilized PP | Crush-proof, moisture-resistant, odor-neutral | 10+ cycles | 40% lower per-use cost vs. cardboard |

| Fruit Tray Inserts | 2mm thickness, food-grade certified | Prevents bruising, easy to sanitize | 7+ cycles | Reduces spoilage by 15% |

Construction Site Protection

Heavy-duty Proplex sheets withstand machinery, debris, and chemical exposure. Flame-retardant options comply with OSHA and local safety codes.

| Application Scenario | Proplex Specification | Key Benefits | Reuse Value | Cost Efficiency |

|---|---|---|---|---|

| Hardwood Flooring Protection | 6mm thickness, FR-rated PP | Scratch-resistant, water barrier | 15+ cycles | Eliminates $5K+ per project carpet replacement |

| Concrete Pouring Protection | 8mm thickness, high-GSM PP | Chemical resistance, load-bearing (up to 5,000 lbs) | 12+ cycles | Saves 50% on site cleanup costs |

Logistics & Shipping

Customizable layer pads prevent cargo shifting, moisture damage, and static discharge during transit. Anti-static and UV-stabilized variants suit electronics and outdoor shipments.

| Application Scenario | Proplex Specification | Key Benefits | Reuse Value | Cost Efficiency |

|---|---|---|---|---|

| Pallet Layer Pads | 2-4mm thickness, 1200gsm PP corrugated | Anti-slip surface, moisture barrier | 8+ cycles | 25% reduction in damaged goods claims |

| Container Lining | 3mm thickness, UV-stabilized PP | Prevents cargo movement, corrosion resistance | 10+ cycles | Lowers insurance premiums by 10% |

Why Partner with EVERPLAST INDUSTRIAL?

Scalable Production: 90,000 tons annual capacity supports orders from 1,000 to 500,000+ square meters with 4-week lead times.

Precision Engineering: 6 extrusion lines ensure ±0.1mm thickness tolerance and uniform material density.

Global Compliance: ISO 9001-certified processes guarantee consistency across flame retardant (FR), anti-static, UV-stabilized, and food-grade variants.

Sustainability Focus: Reusable designs reduce waste by up to 70% vs. single-use alternatives, aligning with ESG goals.

“Proplex isn’t just protection—it’s a strategic asset. Our clients report 20-40% lower operational costs by switching to reusable Proplex solutions.”

— EVERPLAST INDUSTRIAL Technical Director

Ready to optimize your supply chain? Contact us for custom specifications, free samples, and volume pricing.

Email: [email protected] | Website: www.everplast.com

Why Global Buyers Choose Everplast

Partner with Everplast Industrial

Factory-Direct Cost Efficiency

Eliminate distributor markups with direct factory pricing

90,000 tons annual capacity and 6 high-speed extrusion lines enable economies of scale for bulk orders

Up to 30% lower costs versus competitive distributor pricing

Rapid Delivery & Order Assurance

15-day standard lead time for standard orders

Draft deposit policy: 30% deposit secures production slot, 70% before shipment

Global logistics partners ensure 7–10 day international shipping

Technical Expertise & Customization

ISO 9001:2015 certified manufacturing processes with 15+ years of industry expertise

Custom material formulations:

Flame retardant (UL94 V-0 compliant)

UV stabilization for outdoor durability

Anti-static surface treatments

High-GSM (1200gsm+) cushioning layers for superior impact absorption

Application-specific engineering support for:

Automotive underbody protection

Construction site flooring

Agricultural equipment shielding

Logistics palletization

Product Specifications Overview

| Specification | Detail |

|---|---|

| Material | High-impact polypropylene (PP) corrugated sheet |

| Thickness Range | 2mm to 14mm |

| Width | Up to 2100mm |

| GSM | 800gsm to 1200+ gsm |

| Flame Retardant | UL94 V-0 compliant options |

| UV Resistance | Customizable stabilization |

| Anti-Static | Optional surface treatment |

Ready to optimize your surface protection strategy? Contact us today for a custom sample and technical consultation.

Email: [email protected] | Website: www.everplast.com

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.