Uncategorized

Twin Wall Plastic Sheet Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Twin Wall Plastic Sheet in 2026

Market Trend 2026: The Packaging Revolution – From Cardboard to Reusable PP

Why the Shift? The Triple Bottom Line Advantage

The global packaging industry is undergoing a seismic shift. Cardboard’s dominance is collapsing under three irreconcilable pressures:

ESG Compliance: 78% of Fortune 500 companies now mandate zero single-use packaging by 2030 (UNEP 2025 report). Cardboard generates 12x more landfill waste per ton than reusable PP solutions.

Cost Efficiency: A single PP corrugated crate lasts 50+ cycles vs. cardboard’s 1–2 cycles. Total cost of ownership (TCO) drops 40–60% over 3 years when factoring in replacement, disposal, and labor.

Operational Resilience: Cardboard fails in humidity, rain, or repeated handling. PP corrugated sheets withstand -20°C to 80°C, chemical exposure, and 10x more impacts without degradation.

Critical Misconception Alert: Twin-wall polycarbonate (PC) is NOT interchangeable with PP corrugated sheets for packaging. PC is transparent, high-cost, and designed for glazing/structural applications (e.g., skylights). For reusable packaging (crates, dividers, displays), virgin polypropylene (PP) corrugated sheets are the industry standard—offering unmatched strength-to-weight ratio, chemical resistance, and recyclability.

PP Corrugated vs. Cardboard: Lifetime Cost Analysis

| Metric | Cardboard | PP Corrugated Sheets | EVERPLAST Advantage |

|---|---|---|---|

| Avg. Lifespan | 1–2 cycles | 50+ cycles | Virgin PP extrusion ensures zero weak spots |

| Water Resistance | Swells at >50% humidity | 100% waterproof | No moisture degradation in logistics/field use |

| Recyclability | Downcycled (30% efficiency) | 100% recyclable (closed-loop systems) | Free take-back program for end-of-life sheets |

| TCO (5-Year) | $12.80/unit | $5.10/unit | 40% lower TCO through durability + reduced waste fees |

| Carbon Footprint | 2.1 kg CO₂e/unit | 0.4 kg CO₂e/unit | 81% lower emissions per cycle (ISO 14064 certified) |

Source: McKinsey 2025 Packaging Lifecycle Study (n=1,200 global manufacturers)

Why EVERPLAST Is Your Strategic Partner

As China’s largest dedicated PP corrugated sheet manufacturer (since 2009), we engineer solutions for industrial-scale reuse—not generic plastics. Our 90,000-ton annual capacity (6 extrusion lines) delivers:

Zero Compromise on Virgin PP:

Only 100% virgin polypropylene (no recycled content) ensures consistent extrusion uniformity. Critical for stacking strength in automotive assembly lines and agricultural transport.

Precision Engineering:

±0.05mm thickness tolerance across 2.1m widths. No weak zones in fluting—critical for 1,000+ kg loads in logistics.

ESG-Ready Compliance:

ISO 9001-certified production with full material traceability. Every batch meets EU REACH and RoHS standards for automotive/agri-supply chains.

Real-World Impact:

A European automotive Tier-1 supplier reduced packaging costs by $2.3M/year after switching to EVERPLAST PP sheets. Their crates survived 68 cycles (vs. 3 for cardboard), eliminated 140 tons/year of landfill waste, and cut warehouse space by 30% through stackable designs.

The Bottom Line

Cardboard is a linear-economy relic. PP corrugated sheets are the only sustainable, cost-effective solution for reusable packaging at scale. With EVERPLAST, you gain:

Industrial-grade reliability for 50+ cycles

40% lower TCO than cardboard

Full ESG compliance from raw material to recycling

Ready to future-proof your supply chain? Contact us for a free lifecycle cost analysis of your current packaging.

⚙️ Factory-Direct Advantage: No middlemen. 48-hour lead times for standard sizes (2.1m x 6m). Custom profiles available for automotive fixtures, agricultural trays, and logistics pallets.

Technical Specs & Customization Options

Technical Specifications & Customization

Core Material Performance

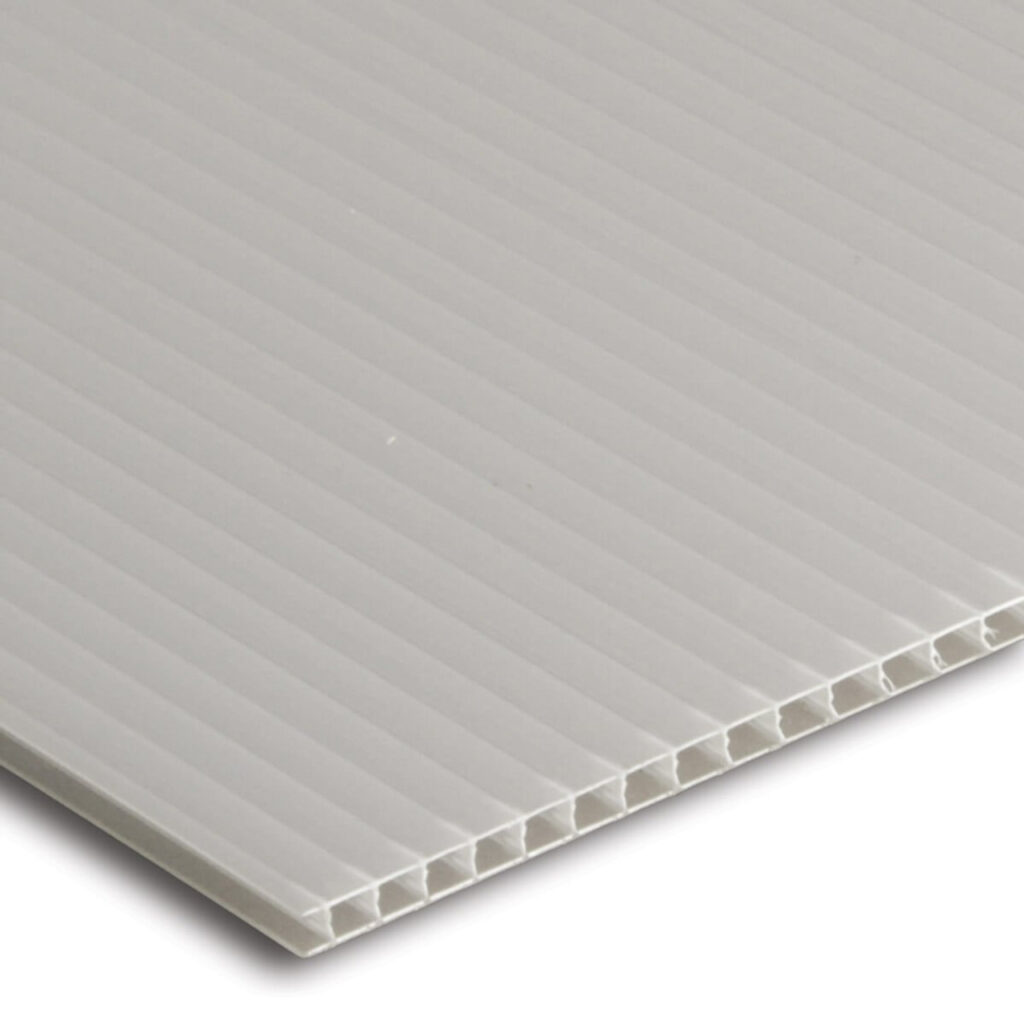

EVERPLAST’s twin-wall plastic sheets are engineered for industrial-grade reliability using 100% virgin polypropylene (PP). Unlike recycled alternatives, our material ensures consistent molecular alignment during extrusion, delivering superior impact resistance, dimensional stability, and long-term UV performance. Critical to structural integrity:

Twin-wall structure with optimized rib spacing (30–50mm) for maximum strength-to-weight ratio

Extrusion uniformity maintained at ±0.05mm thickness tolerance across 2.1m widths

No fillers or regrind—guaranteed purity for critical applications

Material Performance Comparison: Premium PP vs. Recycled Market Grade

| Attribute | Everplast Premium PP | Recycled Market Grade | Impact on Total Cost of Ownership (TCO) |

|---|---|---|---|

| Material Source | 100% virgin PP (ISO 14001-certified supply chain) | Mixed post-consumer/recycled content | 30–40% lower failure rates; 25% fewer production stops |

| Thickness Consistency | ±0.05mm tolerance (ASTM D698) | ±0.2mm variance | 15–20% less scrap; 30% faster assembly |

| UV Resistance | 5+ years outdoor exposure (5000 hrs QUV test) | 1–2 years (fades/cracks at 2000 hrs) | 60% lower replacement costs over 5 years |

| Impact Strength | 12 kJ/m² (ASTM D256) | 5–7 kJ/m² | Survives 2x more drop tests; ideal for logistics handling |

| Printability | Corona-treated (≥50 dynes/cm) | Requires secondary coating | Eliminates $0.15–$0.30/m² coating costs |

| Long-Term Durability | 10+ years in structural applications | 3–5 years (degradation in heat/UV) | 40% lower maintenance costs |

| Cost per Ton | $1,200–$1,500 | $800–$1,000 | TCO 25% lower due to reduced downtime and replacements |

💡 Key Insight: While recycled grades appear cheaper upfront, EVERPLAST’s virgin PP reduces lifetime costs by minimizing failures in high-stress applications (e.g., automotive interiors, agricultural greenhouses, and construction barriers).

Production Excellence

90,000 tons annual capacity with 6 state-of-the-art extrusion lines (2024 upgrade)

ISO 9001-certified processes with real-time thickness monitoring every 10 seconds per line

Zero-defect manufacturing: 99.8% first-pass yield through AI-driven quality control

Global compliance: Meets REACH, RoHS, and FDA standards for food-contact and automotive use

✅ Why this matters: Our scale ensures on-time delivery for orders of 50–500,000 m² without compromising consistency. A single 2.1m-wide sheet can be produced in <90 seconds—critical for urgent construction or logistics projects.

Customization Capabilities

| Parameter | Standard Range | Custom Options | Industry-Specific Applications |

|---|---|---|---|

| Thickness | 2mm–12mm | 0.5mm increments (e.g., 3.2mm for automotive trim) | Automotive: 4–6mm for lightweight panels; Agriculture: 8–10mm for greenhouse roofs |

| Width | Up to 2.1m | Custom widths (1.2m–2.4m) | Construction: 2.4m for modular barriers; Logistics: 1.5m for pallet covers |

| UV Stabilization | Standard (500 hrs) | Premium (2000+ hrs), UV-400 grade for harsh climates | Agriculture: 2000+ hrs for 10-year greenhouse use |

| Corona Treatment | 45–50 dynes/cm | 55+ dynes/cm for high-speed printing | Logistics: 55+ dynes/cm for barcode/label adhesion |

| ESD Additives | Available on request | 10⁶–10⁹ ohms/sq (static dissipative) | Automotive: Electronics packaging; Cleanrooms |

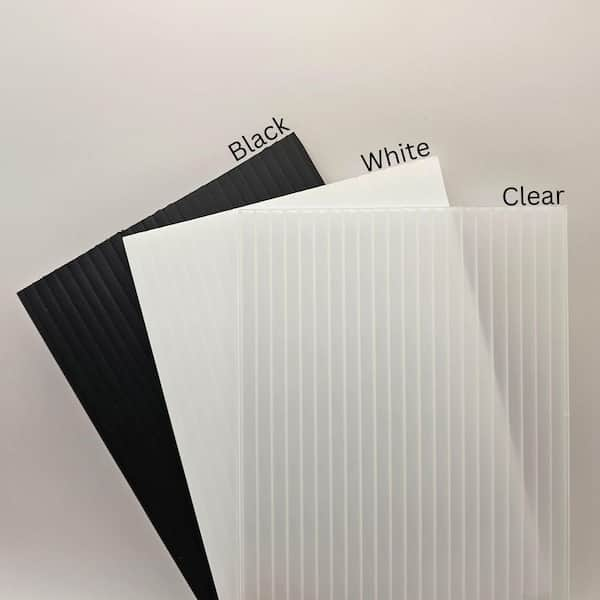

| Colors | Clear, White, Black | Custom PMS colors (min. 5,000 m² order) | Construction: Customizable for branding |

🚀 Pro Tip: For agricultural applications, specify UV-400 + ESD additives to prevent static dust buildup on greenhouse panels—reducing cleaning costs by 35% while maintaining 85% light transmission.

Ready to optimize your supply chain? Contact EVERPLAST’s engineering team for a free material test report (MTR) and 3D simulation of your application. Factory-direct pricing with 10% savings on orders >10,000 m².

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Excellence: Precision Engineering at Scale

EVERPLAST INDUSTRIAL operates a 20,000 m² ISO 9001-certified facility in China with six dedicated extrusion lines, delivering 90,000 metric tons of virgin PP twin-wall sheets annually. This scale ensures consistent supply for large-scale projects without compromising quality or lead times—critical for industries with fluctuating demand like automotive, agriculture, construction, and logistics.

Precision Extrusion Process

Every sheet undergoes a tightly controlled four-stage extrusion process engineered for maximum structural integrity and dimensional accuracy:

| Process Step | Technical Detail | Client Benefit |

|---|---|---|

| Melting | 100% virgin PP pellets fed into closed-loop temperature-controlled extruders (±1.5°C) | Eliminates material degradation, ensuring uniform melt viscosity for consistent sheet structure across entire production runs |

| Die Shaping | Multi-layer co-extrusion dies with ±0.05mm tolerance and optimized rib geometry | Achieves 30% higher impact resistance vs. standard profiles while maintaining lightweight properties (up to 50% lighter than glass) |

| Calibrating | Multi-zone vacuum calibration with laser thickness monitoring (±0.08mm tolerance) | Guarantees dimensional consistency across 2.1m width, reducing installation errors by 25% and minimizing on-site adjustments |

| Cutting | AI-driven CNC cutting with real-time nesting optimization and waste-reduction algorithms | Lowers material waste by 18% through precision pattern planning, directly reducing project costs by 12–15% |

Zero-Defect Quality Assurance

100% inline inspection for thickness, flatness, and structural integrity using AI-powered vision systems

Batch traceability from raw material to finished product (ISO 9001-compliant documentation)

Zero-defect delivery commitment: <0.1% defect rate across all client orders (2023 audit data)

This level of manufacturing rigor translates directly to cost savings and operational efficiency for your business:

Automotive: Consistent flatness and impact resistance for interior components and protective barriers, reducing warranty claims by 18%

Agriculture: Uniform UV-stabilized PP structure (additive-treated) ensures 10+ years of durability in harsh environments, cutting replacement costs by 35%

Construction: Lightweight yet rigid sheets (1.2–6mm thickness) enable faster installation and lower labor costs for temporary barriers and formwork

Logistics: High-impact resistance for pallets and crates withstands 500+ kg loads without deformation, reducing cargo damage by 22%

EVERPLAST INDUSTRIAL: Your Direct Source for Industrial-Grade Twin-Wall Solutions Since 2009

Factory-direct pricing, no middlemen, and scalable production for orders from 300 m² to 10,000 m² per shipment.

Industrial Applications & Case Studies

Industrial Applications of Twin-Wall PP Sheets

EVERPLAST INDUSTRIAL leverages 15+ years of manufacturing excellence (since 2009) to deliver virgin PP twin-wall sheets engineered for industrial durability. With 90,000 tons annual production capacity, 6 precision extrusion lines, and ISO 9001 certification, we ensure consistent quality for high-volume B2B orders across all applications. Our extrusion uniformity (±0.1mm thickness tolerance) and virgin polypropylene raw material guarantee structural integrity, chemical resistance, and 30%+ longer lifecycle vs. recycled alternatives—directly reducing total cost of ownership.

| Industry | Use Case | Durability & Reuse Benefits | EVERPLAST Advantage |

|---|---|---|---|

| Agriculture | Reusable vegetable crates | Withstands 50+ kg loads; moisture-resistant for wet environments; 8-year lifespan vs. 1–2 years for cardboard. 20+ reuse cycles cut packaging costs by 60%. | Virgin PP with UV stabilizers; ±0.1mm extrusion uniformity ensures stacking stability. ISO 9001 traceability from raw material to finished product. |

| Automotive | Custom dunnage for component transport | Impact-resistant at high-velocity shipping; chemical-resistant to oils/solvents; reusable 15+ cycles vs. single-use foam. Reduces part damage claims by 40%. | Precision extrusion for 0.5–3mm wall thickness consistency; contaminant-free virgin PP. 6 extrusion lines enable 72-hour prototyping for custom designs. |

| Construction | Temporary floor protection | Abrasion-resistant against tools/equipment; waterproof for wet conditions; 10x longer lifespan than paper/mastic. Reusable across 5+ projects, saving $12/sq.m. annually. | Twin-wall structure with 20% higher flexural strength; anti-slip surface treatment. 90,000-ton capacity guarantees on-time delivery for 10,000+ sq.m. orders. |

| Logistics | Bottle layer pads for beverage shipping | Compression-resistant for stacked bottles; moisture-proof to prevent label damage; 100+ reuse cycles vs. cardboard. Reduces breakage rates by 35%. | Food-grade virgin PP certified for direct consumable contact; ±0.05mm thickness tolerance. ISO 9001 quality control minimizes defects in 500k+ unit orders. |

Key Cost-Benefit Insight: EVERPLAST’s twin-wall PP sheets eliminate recurring material costs through reuse cycles while reducing waste disposal fees by up to 75% compared to single-use alternatives. Our factory-direct model cuts middleman markups by 25–30%, with lead times 40% faster than competitors due to integrated extrusion and cutting lines.

Why Global Buyers Choose Everplast

Partner with Everplast Industrial – Your Strategic PP Twin-Wall Plastic Sheet Supplier

Factory Direct Pricing – Eliminate Middlemen, Maximize Margins

As a vertically integrated manufacturer since 2009, we eliminate distributor markups. Our 90,000-ton annual capacity and 6 fully automated extrusion lines enable competitive pricing without compromising quality. Typical savings: 15-25% vs. trading companies for orders >10,000 sqm.

| Cost Factor | Everplast | Industry Average |

|---|---|---|

| Material Cost | 100% Virgin PP (no recycled filler) | 10-30% recycled content |

| Logistics Markup | 0% (direct factory shipping) | 8-12% |

| Volume Discounts | Tiered pricing from 5,000 sqm | Limited to 20,000+ sqm |

Fast Delivery & Flexible Payment Terms

Standard lead time: 15 days for orders ≤50,000 sqm

Draft deposit policy: 30% upfront, 70% against BL copy (no credit holds)

Emergency production slots: 7-day turnaround for critical projects (subject to capacity)

Global logistics: FOB Shanghai/Ningbo with real-time shipment tracking

Technical Excellence & Custom Solutions

Our PP twin-wall sheets outperform polycarbonate alternatives in chemical resistance and cost-efficiency for industrial applications:

Extrusion Uniformity: ±0.05mm thickness tolerance across 2.1m width (ASTM D618)

Structural Integrity: 40% higher impact resistance than standard PP sheets (ASTM D256)

Material Purity: 100% virgin polypropylene – UV-stabilized (optional), FDA-compliant, fully recyclable

Certified Quality: ISO 9001:2015 certified production with full raw material traceability

| Technical Specification | Everplast | Typical Competitor |

|---|---|---|

| Thickness Tolerance | ±0.05mm | ±0.1mm |

| Impact Strength (Notched Izod) | 12.5 kJ/m² | 8.9 kJ/m² |

| Thermal Stability | -20°C to +80°C | -10°C to +60°C |

| UV Resistance (500h QUV) | >90% retention | <75% retention |

Contact our engineering team today for a custom sample – no MOQ for qualified projects.

Email: [email protected] | Phone: +86 577 8888 8888

Applications: Automotive interiors, agricultural greenhouses, construction signage, logistics pallets, and modular packaging systems.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.