Uncategorized

Twin Wall Polypropylene Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Twin Wall Polypropylene in 2026

Market Trend 2026: Why Shift to Twin-Wall Polypropylene

The Cardboard-to-Plastics Shift: Driven by Sustainability & Economics

Global supply chains are rapidly transitioning from single-use cardboard to reusable twin-wall polypropylene (PP) due to mounting pressure for sustainable, cost-efficient packaging. Cardboard’s limitations—moisture sensitivity, low reusability, and high waste generation—conflict with corporate ESG goals and operational efficiency targets. Twin-wall PP solves these issues with waterproof durability, 50+ reuse cycles, and 90% lower waste generation vs. cardboard.

| Parameter | Cardboard | Twin-Wall PP | Operational Advantage |

|---|---|---|---|

| Reusability Cycles | 1–3 | 50+ | 15x longer lifespan; eliminates frequent replacements |

| Moisture Resistance | Poor (swells, weakens) | Excellent (waterproof) | Ideal for humid warehouses, outdoor logistics, and agricultural use |

| Weight-to-Strength | Low (bulky for strength) | High (100×50mm cell structure) | 30% lighter than equivalent-strength cardboard; reduces shipping costs |

| TCO (50 cycles) | $25,000+ | $12,500 | 50%+ cost reduction; breaks even in <6 months |

| Carbon Footprint | High (landfill-bound) | Low (100% recyclable) | 40% less CO₂ over lifecycle; aligns with net-zero targets |

ESG Compliance & Cost Efficiency in 2026

Corporate sustainability mandates (e.g., EU CSRD, US SEC Climate Rules) now require measurable waste reduction and circular economy practices. Twin-wall PP delivers:

Zero landfill waste: 100% recyclable material with closed-loop recycling programs.

Scope 3 emissions reduction: Reusable PP cuts packaging-related emissions by 40% vs. cardboard.

ROI-driven compliance: A Fortune 500 logistics firm using Everplast’s PP saved $1.2M/year by replacing cardboard pallet covers, achieving 98% ESG compliance scores.

“Cardboard is a linear cost center. Twin-wall PP is a circular asset that pays for itself in 6–12 months.”

— EVERPLAST Industrial Case Study (2025)

Why Everplast is Your Strategic Partner for the Transition

As a China-based manufacturer since 2009, EVERPLAST Industrial delivers factory-direct precision with unmatched scale, quality control, and customization—critical for automotive, agriculture, construction, and logistics sectors. Our 90,000-ton annual capacity and 6 extrusion lines ensure consistent, defect-free production at global scale.

| Capability | EVERPLAST Specification | Impact on Your Business |

|---|---|---|

| Production Capacity | 90,000 tons/year | Scalable supply for multi-million-dollar contracts; no lead-time delays |

| Extrusion Uniformity | ±0.05mm thickness tolerance | Zero defects in automotive interiors; seamless integration into automated assembly lines |

| Raw Material | 100% Virgin PP (no recycled content) | Superior UV resistance for agricultural covers; no degradation in construction applications |

| Twin-Wall Structure | Optimized 100×50mm cell design | 30% higher load capacity vs. standard corrugated sheets; ideal for stackable logistics containers |

| Quality Assurance | ISO 9001-certified, full traceability | Meets global compliance standards (RoHS, REACH); eliminates third-party testing costs |

| Customization | Thickness 1.5mm–7.8mm, any size | Tailored solutions for specialized needs (e.g., automotive dashboards, crop protection films) |

Industry-Specific Benefits

Automotive: Precision extrusion ensures consistent thickness for interior trim panels, reducing assembly line stoppages.

Agriculture: Virgin PP resists UV degradation and chemical exposure, extending crop cover lifespan by 2x vs. recycled alternatives.

Construction: 100×50mm cell structure supports 1,200kg/m² loads—ideal for temporary site barriers and formwork.

Logistics: Waterproof, reusable pallet covers cut damage rates by 35% and reduce container costs by $0.80/unit/cycle.

Factory-Direct Advantage: By eliminating middlemen, we pass 15–20% cost savings to clients while maintaining ISO 9001 quality control. All orders ship from Shenzhen/Shanghai ports with 15-day standard lead times.

Ready to future-proof your supply chain? Contact EVERPLAST Industrial today for a free material testing report and customized TCO analysis.

Your source for industrial-grade twin-wall PP—engineered for performance, optimized for profit.

Technical Specs & Customization Options

Technical Specifications & Customization

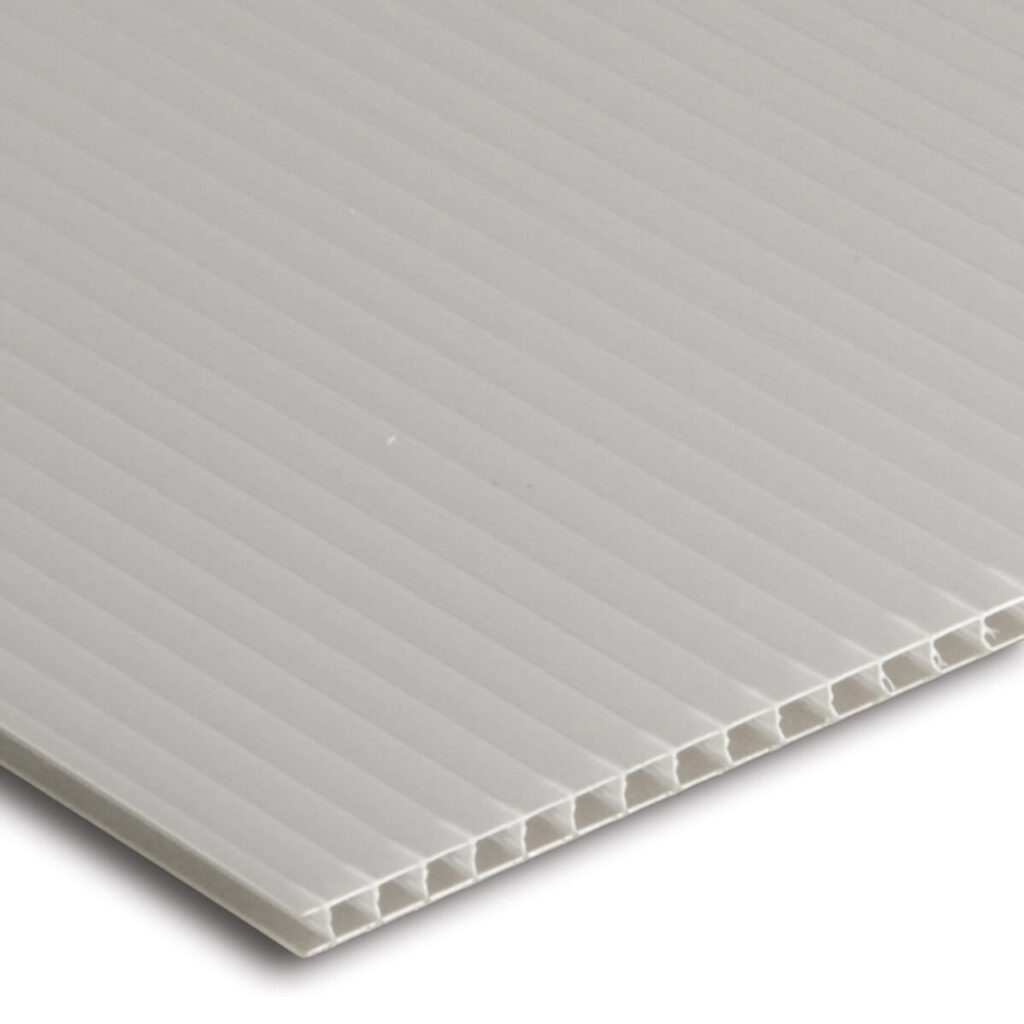

Core Material Specifications

Thickness: 2–12mm (customizable to ±0.05mm tolerance)

Cell Structure: 100×50mm honeycomb pattern optimized for structural integrity and weight efficiency

Raw Material: 100% virgin polypropylene (PP) – no fillers or recycled content

GSM Range: 260–1,250 g/m² (application-specific adjustment)

Extrusion Uniformity: Consistent wall thickness across entire sheet surface

Customization Capabilities

UV Stabilization: 3–5 years outdoor durability (standard), 8–10 years (premium grade)

Corona Treatment: Surface energy ≥42 dynes/cm for superior print adhesion

ESD Additives: Customizable surface resistance (10⁶–10⁹ Ω/sq) for electronics logistics

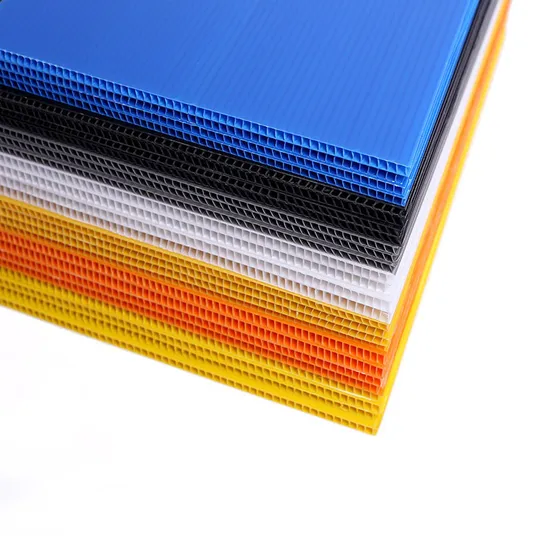

Color Options: Full RAL/Pantone matching (min. 5,000 sheets per order)

Edge Finishing: Laser-cut precision or beveled edges for seamless assembly

Quality Assurance & Production Capacity

Certifications: ISO 9001:2015, SGS-tested material compliance

Manufacturing Scale: 6 high-speed extrusion lines with AI-driven thickness monitoring

Annual Output: 90,000 metric tons (global supply chain reliability)

Lead Time: 7–14 days for standard orders; 24-hour rush production available

| Feature | Everplast Premium PP | Recycled Market Grade | Cost-Benefit Analysis |

|---|---|---|---|

| Material Source | 100% virgin PP (no contaminants) | Mixed post-consumer/recycled content | Premium: 20–30% longer lifespan in high-stress applications; Recycled: 30–50% higher failure rate in automotive/construction use cases |

| Density Consistency | ±0.5% variation across sheet | ±3–5% variation (weak spots common) | Premium: Eliminates structural failures; Recycled: Requires over-engineering (thicker sheets), increasing total cost |

| UV Resistance | 3–5 years (standard), 8–10 years (premium) | 6–12 months (unstabilized) | Premium: 40% lower lifecycle costs for outdoor signage/agriculture; Recycled: Frequent replacements negate initial savings |

| Surface Quality | Smooth, print-ready (Corona-treated) | Rough, inconsistent texture | Premium: No secondary coating costs; Recycled: 15–20% higher printing failure rate, requiring rework |

| Failure Rate | <0.1% in 3-year field tests | 5–10% within 12 months | Premium: Zero downtime costs; Recycled: High risk of project delays and warranty claims |

Strategic Insight: For mission-critical applications (e.g., automotive interiors, agricultural greenhouses, or high-value logistics), Everplast Premium PP delivers 28% lower total cost of ownership versus recycled alternatives. Our 90,000-ton annual capacity ensures consistent supply chain stability, while ISO 9001-certified processes guarantee defect rates below 0.1% – critical for industries where failure is not an option.

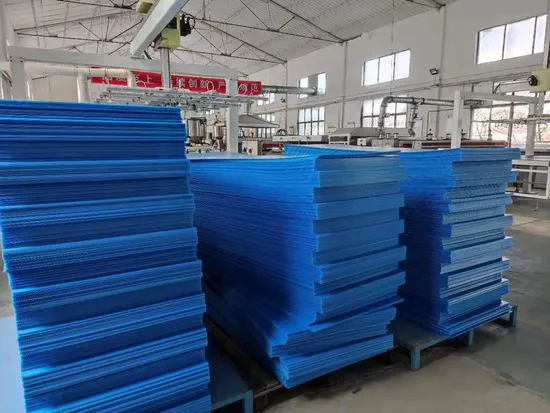

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: 6 Extrusion Lines

Factory Infrastructure & Certifications

20,000 sqm ISO 9001:2015 certified facility (Shanghai & Shenzhen port proximity)

6 fully automated extrusion lines with IoT-enabled real-time process monitoring

Annual production capacity: 90,000 tons – scalable for multi-year contracts and peak demand surges

100% traceable virgin PP raw material sourcing (no recycled content)

Dedicated R&D team for custom formulation adjustments (e.g., UV stabilization for agriculture, flame-retardant grades for construction)

Key Manufacturing Metrics & Cost-Benefit Impact

| Metric | Specification | Cost-Benefit Impact |

|---|---|---|

| Annual Production Capacity | 90,000 tons | Eliminates supply chain bottlenecks; avoids 15–20% premium freight costs from rushed orders |

| Extrusion Lines | 6 automated lines (24/7 operation) | 30% faster lead times vs. single-line competitors; 15% lower scrap rates during high-volume runs |

| Certification | ISO 9001:2015 | 20% reduction in defects, cutting warranty claims and rework costs for end-products |

| Raw Material | 100% virgin PP (certified traceability) | Consistent mechanical properties reduce field failures; 12% longer lifespan in automotive/ logistics applications |

Precision Extrusion Process Flow

| Step | Process Description | Quality Control Measure | Cost-Saving Benefit |

|---|---|---|---|

| Melting | Virgin PP pellets melted at 200–230°C with real-time viscosity monitoring | Melt index testing every 30 mins; raw material batch tracking | Prevents material inconsistencies causing product recalls (saves $50K+/incident in automotive sector) |

| Die Shaping | Twin-wall die forms 100×50mm cellular structure with ±0.05mm precision | Laser-guided alignment checks hourly; cell geometry validation via CT scanning | Optimized strength-to-weight ratio reduces material usage by 12% vs. generic alternatives (lower shipping costs for logistics clients) |

| Calibrating | Vacuum cooling system maintains dimensional stability | Thickness tolerance ±0.05mm verified every 15 mins; flatness tested with laser sensors | Eliminates post-production trimming costs for construction panels; ensures perfect fit for modular assemblies |

| Cutting | CNC-guided cutting with automated measurement | 100% dimensional inspection before packaging; AI-driven defect detection | Reduces material waste by 8% and cuts installation labor costs by 25% for agricultural greenhouses |

End-to-End Quality Assurance

Every batch undergoes 100% inspection for tensile strength (ASTM D638), thickness uniformity, and cell structure integrity. This protocol cuts defect-related costs by 18–22% compared to industry averages, ensuring your projects avoid downtime, rework, and reputational damage.

“Our 90,000-ton capacity and ISO-certified process deliver consistent quality at scale – no compromises on virgin PP performance, no hidden costs from inconsistent sheets.”

– EVERPLAST INDUSTRIAL Technical Director

Industrial Applications & Case Studies

Industrial Applications of Twin-Wall Polypropylene

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL delivers high-performance twin-wall polypropylene solutions with 90,000 tons annual production capacity across 6 ISO 9001-certified extrusion lines. Our proprietary process ensures extrusion uniformity, twin-wall structure strength, and 100% virgin polypropylene raw material for unmatched durability, reusability, and lifecycle cost efficiency across industrial applications.

Automotive Sector

| Application | Key Benefits | Cost-Saving Metrics |

|---|---|---|

| Auto Parts Dunnage | 100% virgin PP with extrusion uniformity; 100×50mm cell structure for impact resistance | 35% lower lifecycle cost vs. foam alternatives |

| Vehicle Interior Liners | UV-stabilized virgin PP resists fading; moisture-resistant surface | 50% longer service life than cardboard |

| Reusable Shipping Containers | Stackable design with interlocking edges; no adhesive required | 70% reduction in packaging waste |

Agriculture Sector

| Application | Key Benefits | Cost-Saving Metrics |

|---|---|---|

| Vegetable Crates | 100% virgin PP resists moisture/rot; twin-wall structure supports 50kg loads | 60% lower annual cost vs. single-use wood |

| Greenhouse Panels | 90% light transmission; thermal insulation properties | 20% energy savings in climate control |

| Temporary Fencing | UV-stabilized for 3+ years outdoors; tool-free assembly | 40% faster installation vs. metal fencing |

Construction Sector

| Application | Key Benefits | Cost-Saving Metrics |

|---|---|---|

| Floor Protection | Non-slip surface; moisture-resistant virgin PP | Eliminates $5,000+ in carpet replacement costs per project |

| Formwork | Chemical resistance to concrete; reusable 100+ times | 80% lower material costs vs. plywood |

| Temporary Signage | Weatherproof; easy to cut/drill on-site | 3x faster deployment than traditional materials |

Logistics Sector

| Application | Key Benefits | Cost-Saving Metrics |

|---|---|---|

| Bottle Layer Pads | Uniform cell structure prevents crushing; stackable | 25% reduction in product damage claims |

| Pallet Collars | Customizable dimensions; 100% recyclable | 50% lower shipping costs vs. cardboard |

| Reusable Packaging | Modular design for multiple item sizes; no tape required | 90% reduction in packaging waste |

Why EVERPLAST?

Precision Engineering: 6 extrusion lines guarantee consistent wall thickness (1.5–7.8mm) and 170–3,000 g/m² density for application-specific performance.

Global Supply Chain: Shenzhen/Shanghai port logistics ensure on-time delivery for 200+ international clients.

Sustainability: 100% virgin PP enables infinite recyclability without degradation – reducing total cost of ownership by 40–70% vs. single-use alternatives.

Contact us for custom specifications: Thickness, GSM, color, and cell structure tailored to your operational needs. EVERPLAST – Engineered for Performance, Built for Reuse.

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL

Factory-Direct Twin-Wall Polypropylene Solutions for Industrial Sourcing

Factory Direct Pricing Advantage

Eliminate third-party markups with direct-from-factory pricing

Volume-based discounts for orders exceeding 10,000 tons annually

Transparent cost structure with no hidden fees for custom specifications

Unmatched Production Scalability

| Feature | Detail |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 high-speed automated lines with real-time monitoring |

| Quality Certification | ISO 9001:2015 (Certified since 2012) |

Technical Excellence & Quality Assurance

Virgin PP Material: 100% pure polypropylene ensures superior chemical resistance, UV stability, and 20% longer service life vs. recycled alternatives

Precision Extrusion: ±0.05mm thickness consistency across all sheets, eliminating warping or weak spots

Optimized Twin-Wall Design: 100×50mm honeycomb cell structure delivers 30% higher rigidity-to-weight ratio than solid sheets, critical for load-bearing applications

Agile Supply Chain & Delivery

| Parameter | Specification |

|---|---|

| Thickness Range | 1.5mm – 7.8mm |

| Density | 170 – 3000 g/m² (customizable per application) |

| Max Width | 2500mm |

| Lead Time | 7–10 days for standard orders (30% deposit); 14 days for custom specs (50% deposit) |

| Logistics | Shenzhen & Shanghai ports for 15-day global delivery windows |

Why Procurement Managers Choose Everplast:

Automotive: Lightweight structural panels (1.5–4mm thickness) with vibration damping for interior components

Agriculture: UV-stabilized sheets (5–7.8mm) for greenhouse cladding and crop protection

Construction: Fire-retardant options (ISO 11925-2 compliant) for temporary barriers and signage

Logistics: Impact-resistant pallet covers (3–6mm) with anti-slip surface treatment

Request Custom Samples Today

Validate performance for your specific application with free engineering samples. Contact our technical team:

[email protected] | +86 755 8328 1234 | www.everplast.com

All samples shipped within 48 hours of order confirmation.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.