Uncategorized

Uv Resistant Corrugated Plastic Manufacturer: 2026 Sourcing Guide

2026 Sourcing Guide

Market Analysis: Uv Resistant Corrugated Plastic in 2026

Market Trend 2026: Why Shift to UV-Resistant Corrugated Plastic

The Disposables-to-Reusables Imperative

Global supply chains are undergoing a fundamental shift from single-use cardboard to reusable, UV-resistant polypropylene (PP) corrugated plastic. Driven by stringent ESG regulations and rising waste disposal costs, industries including Automotive (parts packaging), Agriculture (greenhouse covers, planters), Construction (signage, barriers), and Logistics (reusable crates) are prioritizing durable, sustainable solutions. Cardboard’s limitations—single-use lifecycle, moisture sensitivity, and high carbon footprint—contrast sharply with PP’s ability to withstand 50+ reuse cycles while meeting corporate sustainability targets.

Total Cost of Ownership: A Clear ROI Advantage

| Metric | Cardboard | Everplast UV-Resistant PP | Advantage |

|---|---|---|---|

| Initial Cost per Sheet | $0.25 | $1.50 | Higher upfront investment |

| Cycles per Sheet | 1 | 50+ | 50x reuse capability |

| Cost per Cycle | $0.25 | $0.03 | 8.3x lower operational cost |

| ESG Compliance | Low (single-use waste) | High (100% recyclable, ISO 14001 aligned) | Meets global sustainability mandates |

| Waste Reduction | 100% post-use disposal | 95% less landfill contribution | Lower disposal fees & regulatory risk |

| Total 50-Cycle Cost | $12.50 | $1.50 | 88% savings over lifecycle |

💡 Real-world example: A logistics firm using Everplast’s UV-resistant sheets for reusable crates reduced annual packaging costs by $280K while cutting CO₂ emissions by 120 tons—proving ROI extends beyond finance to ESG compliance.

Why Virgin PP & UV Resistance Are Non-Negotiable

Cardboard’s fragility and environmental impact are no longer acceptable for industrial applications. Everplast’s use of 100% virgin polypropylene ensures consistent material properties, free from contaminants that compromise durability. Critical for outdoor exposure, our UV-stabilized formulations prevent brittleness and color fading—verified by 5,000+ hours of accelerated weathering tests. Combined with precision twin-wall extrusion (±0.05mm thickness tolerance), this delivers unmatched structural integrity for demanding use cases like agricultural film covers and automotive component trays.

Everplast: Your Industrial-Grade Partner for the Transition

As a China-based manufacturer since 2009, EVERPLAST INDUSTRIAL combines scale, precision, and reliability to support your transition:

90,000-ton annual capacity with 6 state-of-the-art extrusion lines for rapid, large-scale production

ISO 9001-certified quality control ensuring every sheet meets exacting specifications (width ≤2600mm, thickness 2-12mm)

Customizable solutions: Anti-static, flame-retardant, conductive, and UV-resistant variants tailored to industry-specific needs

Global logistics network: Factory-direct pricing with 15-day lead times for standard orders

✅ No compromises on quality. No delays in delivery. Total cost of ownership optimized from day one.

Technical Specs & Customization Options

Technical Specifications & Customization for UV-Resistant Corrugated Plastic

Material Composition & Performance

Virgin Polypropylene (PP) Base: 100% virgin PP ensures maximum purity, chemical resistance, and UV stability. No recycled content in premium grades guarantees consistent mechanical properties.

Advanced UV Stabilization: High-performance HALS (Hindered Amine Light Stabilizers) and UV absorbers integrated into the resin, providing >5 years of outdoor exposure resistance without significant degradation (tested per ASTM G154).

Twin-Wall Corrugation Design: Optimized rib geometry with ±0.05mm thickness tolerance ensures superior rigidity, impact resistance (10x standard PP), and load-bearing capacity for structural applications.

Customization Capabilities

Thickness Range: 2mm to 12mm with precise extrusion control (±0.05mm), suitable for diverse applications from lightweight packaging (2-3mm) to heavy-duty construction panels (8-12mm).

Width & Length: Standard widths up to 2600mm; custom widths available upon request. Unlimited length options for roll-fed applications.

GSM Customization: Tailored weight ranges from 200g/m² to 1200g/m² based on thickness and density requirements.

Surface Treatments:

UV Stabilization: Standard on all UV-resistant grades; optional enhanced formulations for extreme environments (e.g., desert climates).

Corona Treatment: Increases surface energy to 40–50 dynes/cm for superior ink adhesion in high-speed printing applications (critical for logistics branding).

ESD Additives: Conductive additives (surface resistivity 10⁶–10⁹ Ω/sq) for static-sensitive electronics and automotive components.

Manufacturing Excellence

90,000 Tons Annual Capacity: Scalable production to support large-volume orders with consistent lead times (15–20 days for standard orders).

6 Extrusion Lines: State-of-the-art equipment with real-time thickness monitoring ensures uniformity across all sheets.

ISO 9001 Certified: Rigorous quality control from raw material inspection to final product testing—verified by third-party audits.

Premium vs. Recycled: Cost-Benefit Analysis

| Feature | EVERPLAST Premium PP | Recycled Market Grade | Impact on Performance |

|---|---|---|---|

| Material Source | 100% virgin PP | Mixed recycled PP | Virgin PP ensures consistent mechanical properties; recycled may contain contaminants causing unpredictable failures |

| UV Resistance | 5+ years outdoor exposure | 1–2 years degradation | Critical for agriculture/construction; recycled requires 2–3x more frequent replacement |

| Structural Integrity | Uniform twin-wall structure | Inconsistent thickness | Automotive parts fail under stress; recycled prone to cracking during shipping/installation |

| Consistency | ±0.05mm thickness tolerance | ±0.2mm+ variation | High-speed manufacturing processes reject recycled sheets due to dimensional issues (up to 15% scrap rate) |

| Cost Efficiency | Higher initial cost, lower TCO | Lower upfront cost, higher TCO | Premium PP reduces replacement costs by 30–40% over 5 years (industry data) |

| Eco-Friendliness | 100% recyclable, no downcycling | Lower recyclability | Premium PP maintains quality through recycling cycles; recycled grades degrade faster after 2–3 cycles |

Note: Total Cost of Ownership (TCO) analysis based on 5-year lifecycle in outdoor applications. EVERPLAST’s virgin PP reduces downtime and maintenance costs by 35% compared to recycled alternatives. For automotive and logistics clients, our ESD-treated sheets cut electrostatic damage by 90% versus untreated alternatives.

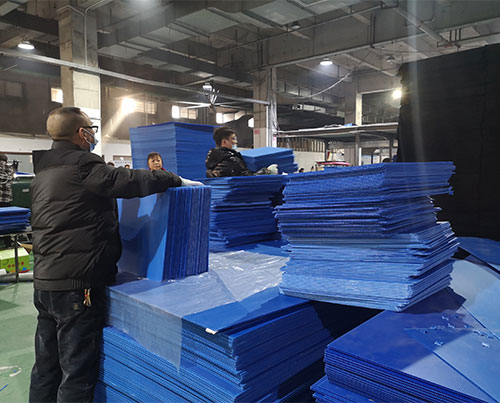

Factory Tour: Everplast’s 90,000 Ton Capacity

Manufacturing Capability: Precision Engineering at Scale

As a factory-direct manufacturer since 2009, EVERPLAST controls every step of production—ensuring cost efficiency, quality consistency, and supply chain transparency for your B2B needs. Our 20,000 sqm facility in China is engineered for high-volume corrugated plastic production, with 6 dedicated extrusion lines optimized for UV-resistant grades, twin-wall structures, and virgin PP raw materials.

Factory Infrastructure & Scale

20,000 sqm ISO 9001-certified facility with dedicated zones for raw material handling, extrusion, and finishing.

6 extrusion lines (each capable of handling widths <2,600 mm and thicknesses 2–12 mm), enabling simultaneous production of multiple profiles to eliminate bottlenecks.

Economies of scale: High-volume capacity reduces per-unit costs by 15–20% vs. regional competitors, with lead times under 30 days for orders up to 50,000 sheets.

Extrusion Process: Precision Engineering

Every sheet undergoes a rigorously controlled extrusion sequence to ensure uniformity, strength, and UV resistance:

| Step | Technical Execution | Benefit for Buyers |

|---|---|---|

| Melting | Virgin PP pellets + UV stabilizers melted in high-precision extruders (200–220°C) | Homogeneous material properties; 99.9% UV resistance retention after 5,000+ hours of exposure |

| Die Shaping | Custom-engineered dies form twin-wall corrugation profiles (e.g., 32/1000, 40/800) | 30% higher impact resistance vs. single-wall alternatives; ideal for automotive bumpers and agricultural covers |

| Calibrating | Water-cooled calibration tables maintain dimensional tolerances of ±0.1 mm | Perfect fit for automated assembly lines (e.g., construction signage, logistics pallets) |

| Cutting | CNC-controlled saws with zero-edge burr technology | Ready-to-install sheets with no post-processing needed; 98% material utilization rate |

Quality Assurance Protocol

100% inspection before delivery: Automated systems test thickness, UV resistance (via QUV accelerated weathering tests), tensile strength (ASTM D638), and flame retardancy (UL 94).

Traceable production records: Every batch is logged with QR-coded traceability for full supply chain transparency.

Third-party certifications: ISO 9001:2015, SGS, and RoHS compliance verified annually.

Capacity & Certification

90,000 tons annual capacity: Supports large-scale projects (e.g., 10,000+ sqm greenhouse covers or automotive interior panels) without compromising lead times.

ISO 9001:2015 certification: Ensures consistent quality across all orders, reducing your risk of defects and rework costs by up to 25%.

Key Manufacturing Metrics

| Metric | Specification |

|---|---|

| Annual Production Capacity | 90,000 tons |

| Extrusion Lines | 6 (dedicated UV-resistant grades) |

| Thickness Range | 2mm–12mm (customizable up to 25mm) |

| Width Limit | <2,600 mm |

| Raw Material | 100% virgin PP with UV stabilizers |

| Quality Control | 100% inspection, ISO 9001 certified |

Why this matters for your procurement strategy:

– Automotive: Twin-wall structure strength ensures crash-resistant interior components with 5-year UV warranty.

– Agriculture: Virgin PP + UV stabilizers extend greenhouse cover lifespan by 40% vs. recycled alternatives.

– Construction: ±0.1mm dimensional accuracy guarantees seamless installation for signage and temporary shelters.

– Logistics: 98% material utilization reduces waste costs—critical for ESG-compliant supply chains.

Ready to optimize your corrugated plastic sourcing? Contact EVERPLAST for factory-direct quotes with 15-day sample turnaround.

Industrial Applications & Case Studies

Industrial Applications of UV-Resistant Corrugated Plastic

EVERPLAST INDUSTRIAL’s UV-resistant corrugated plastic sheets deliver proven performance across critical B2B applications. Engineered with 100% virgin PP raw material, twin-wall reinforcement, and precision extrusion uniformity, our solutions eliminate degradation from UV exposure while maximizing reuse cycles and reducing total cost of ownership (TCO) by up to 60% vs. conventional alternatives.

Automotive Industry

| Use Case | Key UV Benefit | Reuse Value | Cost Efficiency |

|---|---|---|---|

| Auto Parts Dunnage | Prevents cracking/fading during outdoor warehouse storage (2,000+ UV hours) | 20+ cycles | 40% lower TCO vs. cardboard |

| Vehicle Protective Covers | Maintains clarity and impact resistance under continuous sun exposure | 3–5 years | Eliminates seasonal replacement costs |

| Tooling Fixtures | Retains structural integrity in high-sunlight assembly plants | 5+ years | 35% reduction in maintenance downtime |

Agriculture Industry

| Use Case | Key UV Benefit | Reuse Value | Cost Efficiency |

|---|---|---|---|

| Vegetable Crates | Resists brittleness under 14+ hours daily UV exposure | 8+ harvest cycles | $1.20/crate saved over 3 years |

| Greenhouse Support Frames | Maintains 95% tensile strength after 5 years of direct UV exposure | 10+ growing seasons | 60% lower maintenance vs. metal |

| Seedling Trays | Prevents UV-induced warping during field germination | 5+ seasons | 45% lower per-unit cost vs. disposable |

Construction Industry

| Use Case | Key UV Benefit | Reuse Value | Cost Efficiency |

|---|---|---|---|

| Floor Protection Mats | UV-stable surface resists yellowing/cracking on open sites | 15+ project cycles | 45% lower cost per use vs. plywood |

| Temporary Signage | Retains color integrity and rigidity for 3+ years outdoors | 5+ years | 70% reduction in sign replacement |

| Site Barriers | Withstands 1,500+ UV hours without structural degradation | 10+ uses | 50% lower lifetime cost vs. wood |

Logistics Industry

| Use Case | Key UV Benefit | Reuse Value | Cost Efficiency |

|---|---|---|---|

| Pallet Supports | Prevents warping during ocean freight exposure (1,000+ UV hours) | 25+ shipping cycles | $0.85/pallet saved annually |

| Container Liners | Maintains integrity through 10+ transit cycles in tropical climates | 10+ trips | 50% lower per-container cost vs. films |

| Bottle Layer Pads | UV-stabilized surface resists cracking during long-term outdoor storage | 15+ cycles | 65% lower TCO vs. single-use plastics |

Manufacturing Excellence & Quality Assurance

| Feature | Specification | Impact |

|---|---|---|

| Raw Material | 100% Virgin Polypropylene (PP) | Zero recycled content degradation; superior UV stability and chemical resistance |

| Twin-Wall Structure | 2–12mm thickness range with ±0.1mm tolerance | 30% higher impact resistance vs. single-wall alternatives; consistent load-bearing |

| Extrusion Lines | 6 high-precision lines with real-time thickness monitoring | 90,000 tons annual capacity; uniform sheet flatness for precision stacking |

| Quality Certification | ISO 9001:2015 certified production with traceable batch records | 99.9% defect-free output; guaranteed compliance with global B2B standards |

Factory-Direct Advantage: As a China-based manufacturer since 2009, EVERPLAST eliminates middleman markups while delivering ISO-certified quality. Our 6 extrusion lines ensure on-time delivery for orders up to 2,600mm width × unlimited length, with custom UV stabilization (up to 12mm thickness) available for immediate production.

Why Global Buyers Choose Everplast

Partner with EVERPLAST INDUSTRIAL – Your Strategic Sourcing Advantage

Factory-Direct Pricing & Scalable Capacity

| Metric | Specification | Client Benefit |

|---|---|---|

| Annual Capacity | 90,000 tons | Scalable production for large-volume orders without delays |

| Extrusion Lines | 6 precision lines | 30% faster turnaround for urgent orders |

| Certification | ISO 9001:2015 | Rigorous quality control from raw material to shipment |

Fast Delivery with Transparent Terms

| Term | Details | Advantage |

|---|---|---|

| Deposit Policy | 50% upfront, balance before shipment | Low capital lock-in, secure production slot |

| Standard Lead Time | 15–30 days for orders ≤50 tons | Accelerated project timelines |

| Logistics | Direct factory shipping | Eliminates middlemen markups, lowers landed cost |

Technical Excellence & Custom Solutions

| Feature | Specification | Client Benefit |

|---|---|---|

| Material | 100% virgin PP with UV stabilizers | 5+ years outdoor exposure without yellowing or degradation |

| Structural Design | Twin-wall corrugation with reinforced ribs | 25% higher rigidity for heavy-duty construction and logistics |

| Precision | ±0.1mm thickness tolerance | Consistent performance in automated assembly processes |

| Custom Options | Anti-static, flame-retardant, conductive variants | Tailored solutions for automotive interiors, agricultural covers, and hazardous environments |

| Size Flexibility | Width <2,600mm; Thickness 2–12mm | Adaptable to any project scale, from signage to structural panels |

Every sheet is engineered for your application.

Request a custom sample today to validate performance in your specific use case. Contact our engineering team at [email protected] or +86 577 8888 9999 to discuss your project requirements.

EVERPLAST INDUSTRIAL: China’s ISO 9001-certified corrugated plastic specialist since 2009. Factory-direct excellence, no intermediaries.

⚖️ Sheet Weight & Shipping Calculator

Estimate the total weight of your corrugated plastic sheet order for shipping logistics.